Model SH-2012AH-QG

Cutting Machine

(

C002

)

30

7.5. Control Parameters Setting

In the SETUP submenu, press [F5] key to enter control parameters setting window, as shown in Fig. 7.6

Flame/plasma option

——

Take 0 for flame machining and 1 for plasma machining.

Move hole option

——

0 stands for disabling the option and 1 for enabling the option.

No-pretreatment pattern

——

The normal machining procedure is to machining program first to calculate the maximum value

and the minimum value of the pattern. However, it might take too long to handle a large program. Therefore, it is allowed to set

the maximum value and the minimum value of pattern in advance without pattern pretreatment(see the parameters below). The

system will machine the workpiece when drawing the pattern.

X-axis width of steel plate ----

The actual width of steel plate along X axis, which is enabled only in running extra large

program.

Y-axis height of steel plate ----

The actual height of steel plate along Y axis, which is enabled only in running extra large

program.

Common edge option

——

Since the system may control three kinematic axes, this option is used to determine the 3rd axis(Z

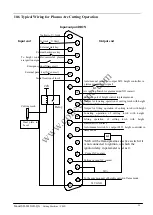

Fig.7.5 Plasma Parameters Setting

SETUP

main

menu

Parameters

display zone

ESC key

Parameter

setting range

Remarks

zone

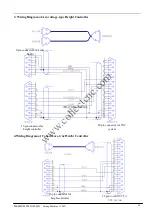

Fig. 7.6 Control parameters menu

SETUP main menu

Parameters

display

zone

ESC key

Parameter setting

range

Remarks zone

www.collectcnc.com