Model SH-2012AH-QG

Cutting Machine

(

C002

)

48

main

window

after machining

program

is

started.

e system; initialize the sy

stem if any parametric pr

oblem.

ram has bug.

The system can

only

machine

straight line and

fail to machine a

circle.

Initialize the system if an

y parametric problem

Initialize the system parameters.

Replace the machining pr

ogram and test run again.

If no more problem, check

that machining program.

Check the program or return it to the

manufacturer for diagnosis.

Screen

blinks

when a solenoid

valve is opened

or plasma arc

ignition is going

on.

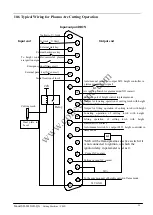

a. The power supply unit for plasma, CNC system and the enclosure of machine must shar

e a ground wire that is 2mm thick at least in diameter and well connected to the ground.

b. Shielded cables must be used for the system input/output and the exposed part at the ca

ble end must not be longer than 30mm.

c. The unused input end must be connected to 24V ground wire.

d. A 0.01uF capacitor should be used between the 24V ground wire and enclosure(shielded

cable).

e. Use an isolation transformer(380V-220V) and as interference suppressor if it is possible.

f. Separate the operational power supply for high-power welding machine/cutting machine fr

om that for CNC system.

Failure to save

the program or

clobber

Failure to save the progra

m.

After replacing batteries, press G, G a

nd 3 in the system main window succ

essively to format the program area.

No

system

output

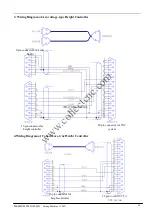

Check if 24V power supp

ly is normal or not.

Measure the voltage betwe

en Pin 24 and Pin 25.

Check and replace the switching powe

r supply unit.

Check if the four relays

on the rear panel are reli

ably connected, if the rela

y operation is normal and

if the contact is function

al.

Replug or replace the relays.

www.collectcnc.com