Pneumatic chain hoist CPA ATEX

15 of 21

Parts subject to wear are:

Stop washers (item 6, 23, 30), needle bearings (item 8, 24, 31), O-rings

and packing rings (item 4, 16, 18, 43) as well as the seal (item 45).

Assembly

Installation should be performed only on the basis of the sectional

drawing. Installation takes place essentially in the reverse order of the

dismantling.

Special care should be taken for clean and correct installation of planet

gears (item 7) with needle bearings (item 8) in equal sorting and stop

washers (item 6) as well as spacer rings (item 9) in the planet gear

carrier (item 3).

The brake friction pads (item 28) on either side of the ring gear (item 29)

must be installed oil-soaked (leave in oil for 1 hour before installation).

The exact adjustment of the overload device is only possible when the

lifting device is completely reassembled. Pre-adjustment of the cup

spring (item 41) is made with the fi xing screw (item 42). After the exact

adjustment has been made, the fi xing screw (item 42) is secured by

means of the ball (item 46) and the threaded pin (item 47).

The gearbox is to be fi lled with approx. 0.3 Litre of gearbox oil

(CLP 460, DIN 51547).

Afterwards the fi ll hole can be closed with the screw plug (item 44) and

the seal (item 45).

8.8 MAINTENANCE OF THE MOTOR

Motor

The life and performance of the hoist motor are properly determined by:

a) the purity of the air

b) the lubrication conditions and maintenance

to a) If rust can form and water can settle in the supply pipe, dirt and

water separators should be installed upstream.

to b) resin- and acid-free lubricating oils (SAE 5W - SAE 10W) should

always be used. Viscous oils stick to the lamellae and aff ect the starting

and effi

ciency of the motor. The lifespan can be signifi cantly increased

through optimum lubrication. We therefore recommend the prefi xing of

maintenance units and oils.

The oilers should be set in such a way that for every m

3

/min. of air

consumption, approx. 2-5 drops are sprayed.

Wear parts - especially the lamellae - should be replaced at the right

time. They are worn out when their width is less than 25 mm (Fig. 19).

The rings (item 18) working as start-up aids must also be replaced with

the lamellae.

O-Ring

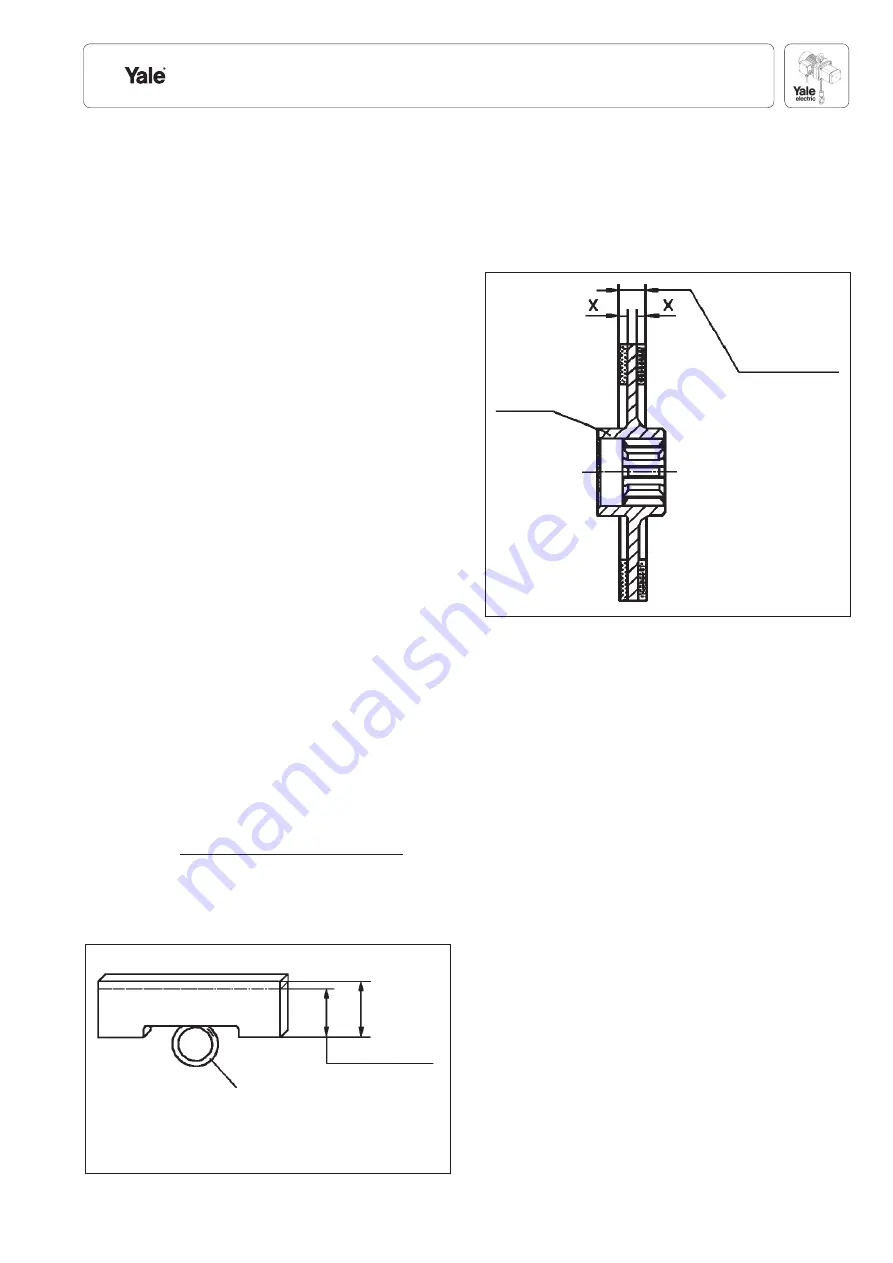

The main wear parts include the brake disk (item 44). The thickness of

the brake lining must be regularly checked, as wear of the lining aff ects

the retention force.

The brake disk is to be changed when the lining thickness is less than

7.5 mm or the lining has worn out on one side and falls below the

dimension x = 2 mm (Fig. 20).

Disassembly and assembly

Dismantling - lamellae and brake disc change

1. Changing lamellae

Loosen the screw (item 27), remove the motor cover (item 25) and cup

spring (item 24). Pull out the sealing plate with the clutch bearing (item

20) from the rotor seat using an extraction device, remove the spacer

ring (item 23). Remove the lamellae (item 17) from the rotor slots.

If no extraction device is available, the complete inner parts can also

be taken out of the motor housing and dismantled further on the work-

bench. To detach the sealing plates (items 5 & 20) from the rotor seat,

slightly pressing a wooden board on to the shaft ends may be helpful.

The cylinder socket (item 9) can be removed and the lamellae (item 17)

can be taken out of the rotor slots.

Before replacing the lamellae, clean the rotor slots of oil and resin resi-

dues. The new lamellae must easily fi t into the slots of the rotor (item 12).

2. Replacing brake discs

Loosen the screws (item 33) and remove the motor housing lid (item

32). Remove the springs (item 55).

Attention:

The pressure springs (item 53) are under tension.

Remove the brake housing lid (item 54) and the pressure springs (item

53). Pull out the brake air housing (item 46) complete with (item 47-

52) from the brake housing (item 40). Pay attention to the O-ring (item

45). Pull out the brake disc (item 44) from the rotor pin and check the

thickness of the lining.

Before the installation/assembly, the brake housing (item 40) and the

pressure plate (item 51) must be cleaned of brake dust. The shaft end

of the rotor (item 12, splining) as well as the hole of the brake disc (item

44) must be coated with a rust protection paste (e.g. Altemp Q NB 50)

to guarantee mild movement of the brake disc (item 44) on the rotor pin

(item 12). This also applies to the teething of the pressure plate (item

51) and the brake housing (item 40).

Fig. 20

Fig. 19

< 25 mm change

Brake disc assembly

Installation 9 mm

< 7.5 mm change

x installation 3 mm

< 2 mm change

31.9 mm

Installation

measurement