BRA2 - BRN2

EN

23

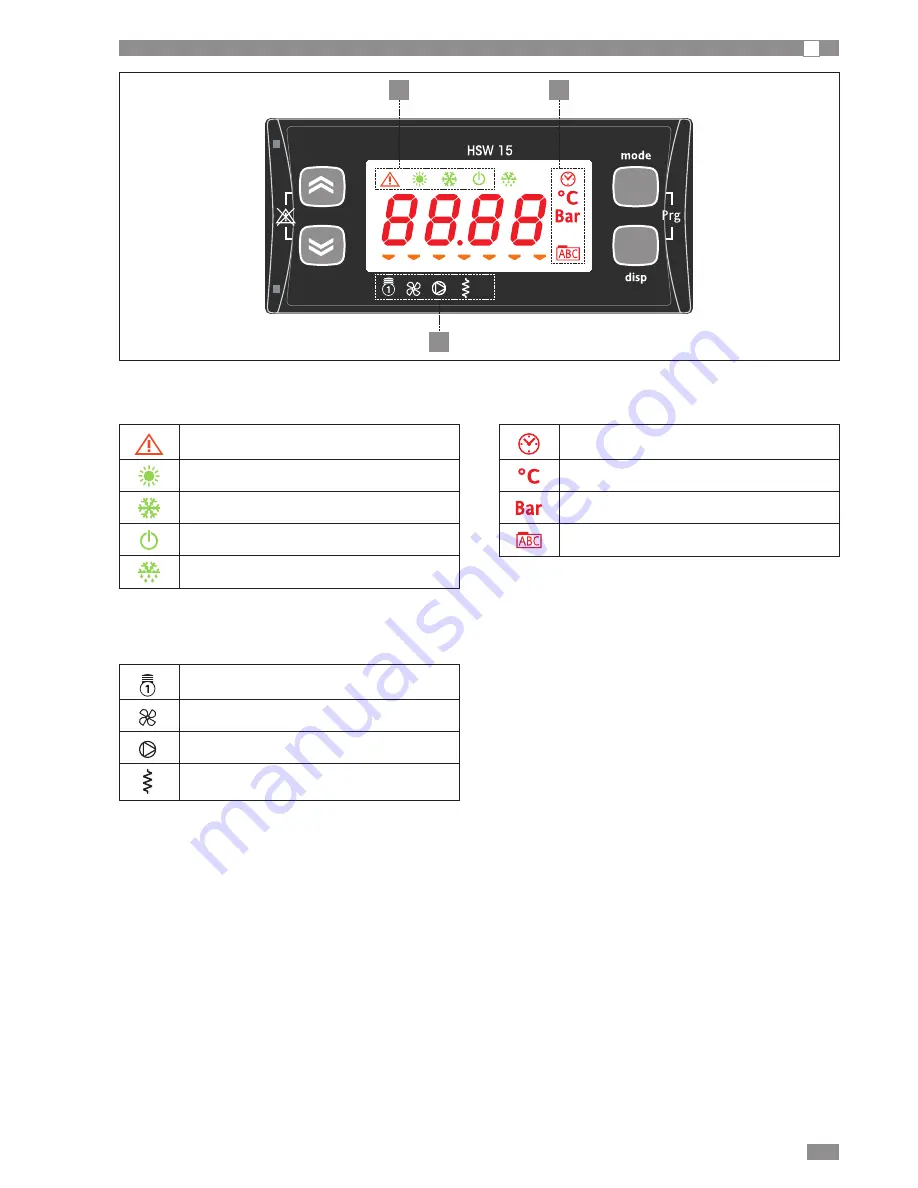

LEDS AND DISPLAY

A

Alarm

Heating

Cooling

Standby

Defrost

1 STATUS AND OPERATING MODE LEDS

Compressor

Fans

System pump

Frost protection heater system heat exchanger

3 UTILITY LEDS

Clock

Degrees centigrade

Pressure (Bar)

Menu (ABC)

2 VALUE AND UNIT OF MEASURE LEDS

set

esc

1

3

2