KETTLE JACKET CLEANOUT AND PASSIVATION PROCEDURES

The following procedure should be preformed at least once every three years to prevent possible corrosion

and ensure the optimum life of the kettle.

DESCRIPTION

- Molyfilm 315 inhibits corrosion in

stainless steel and copper. A pH buffer is present to

assist in maintaining the appropriate pH to assist in

corrosion inhibition.

DISPOSAL

- Follow all Federal, State and local codes

when disposing of product.

SHELF LIFE

- Molyfilm 315’s effectiveness will

diminish after three years.

REFILL QUANTITIES

(ORDERING INFO: 1 Liter

Molyfilm 315 Rust Inhibitor - Part# KE600340-1)

IIM

MP

PO

OR

RT

TA

AN

NT

T: To ensure satisfactory mixing follow the

MIXING / FILLING PROCEDURE described below.

Kettle Size

Volume of Water

Volume of Molyfilm 315

U.S. Gal. Liters

oz.

cc (ml.)

25 U.S. Gal.

4.4

16.6

6

176

MIXING / FILLING PROCEDURE

1.

Refer to chart to determine the required volumes of

water and Molyfilm 315.

2.

In a separate container mix 1/2 gallon of the required

volume of water with the total required volume of

Molyfilm 315.

3.

Pour mixture into kettle.

4.

Pour the remaining required volume of water into kettle.

WARNING:

IMPROPER REFILLING OF KETTLE JACKET WILL

RESULT IN IRREVERSIBLE DAMAGE TO UNIT

.

DANGER:

MOLYFILM 315 IS CORROSIVE, AVOID

CONTACT WITH SKIN AND EYES.

DANGER:

AVOID INHALATION - VAPORS FROM

MOLYFILM 315 MAY BE HARMFUL OR FATAL.

DANGER:

PRESSURE RELIEF VALVE WILL

EXHAUST HIGH TEMPERATURE STEAM.

CONTACT WITH SKIN COULD RESULT IN

SERIOUS BURNS. KEEP FACE, HANDS

AND BODY CLEAR OF DISCHARGE

.

DANGER:

WORKING ON MACHINES WITH

POWER COULD RESULT IN SEVERE

ELECTRICAL SHOCK.

DANGER:

EXTREMELY HOT SURFACES.

WORK ONLY ON COLD KETTLE.

Flushing Procedure

1.

Ensure kettle is at room temperature and

pressure gauge showing zero or less

pressure.

2.

Shut off and disconnect gas supply.

3.

Remove electrical plug from power source.

4.

Remove bolts holding kettle to tabletop/floor.

5.

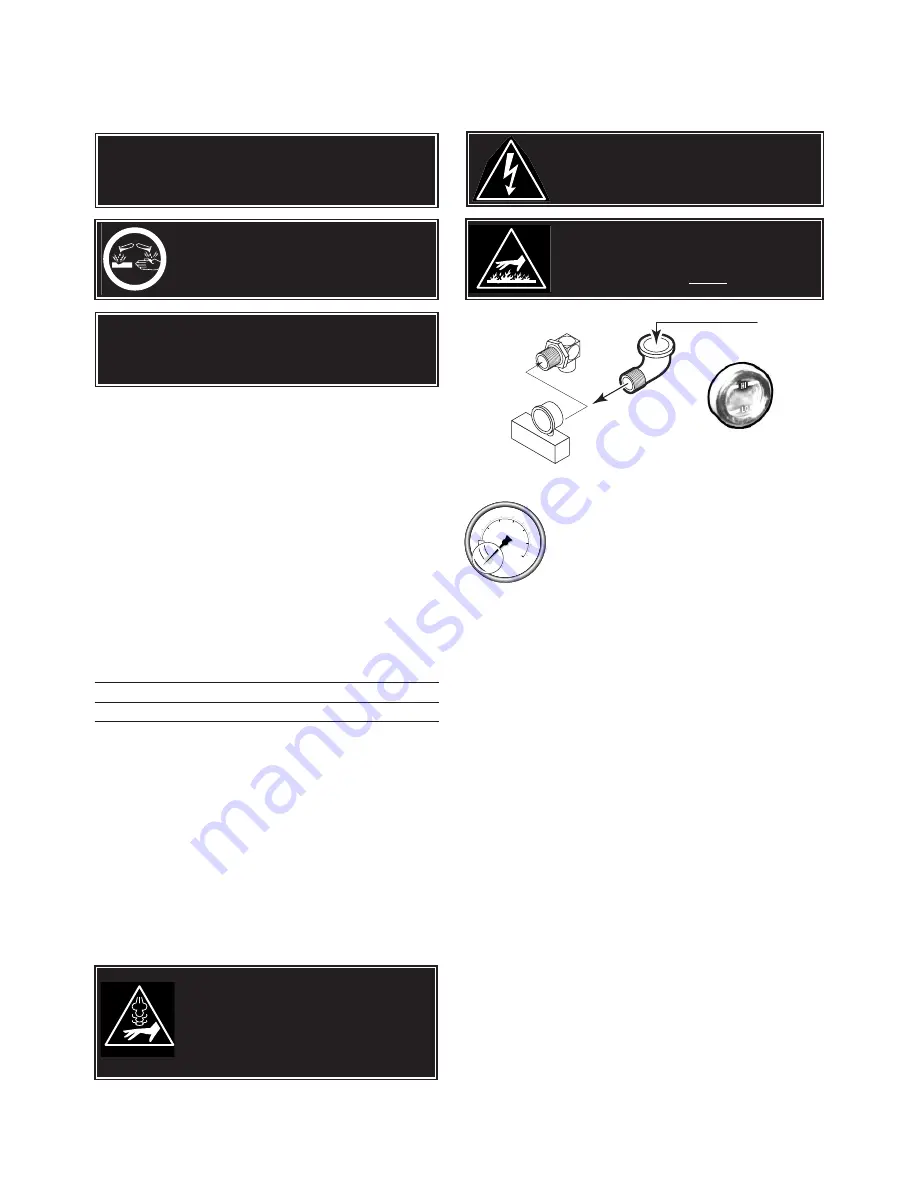

Pull ring on pressure relief valve to insure there

is no pressure within the kettle jacket.

6.

Remove pressure relief valve.

7.

Replace pressure relief valve with street elbow.

8.

Remove sight glass.

9.

Tilt kettle on its side (sight glass down) and allow to

drain. Flush out as much debris as possible with water.

10.

Tilt kettle upright, apply a thread sealant (i.e. Teflon

tape) to the sight glass threads and replace.

11.

Fill jacket via the street elbow with a mixture of water

and Molyfilm 315 (see REFILL QUANTITIES).

12.

Remove street elbow.

13.

Apply a thread sealant (i.e. Teflon tape) to the pressure

relief valve and replace.

14.

Reconnect gas and electrical supplies.

15.

Turn kettle on, vent and heat to high for 1/2 hour.

16.

Cool and drain kettle as per above procedure.

Refilling Unit

1.

Apply a thread sealant (i.e. Teflon tape) to the sight

glass threads and replace.

2.

Fill kettle jacket with a mixture of water and Molyfilm

315 (see REFILL QUANTITIES charts).

3.

Apply a thread sealant (i.e. Teflon tape) to the filler

plug threads and replace.

4.

Turn kettle on and check for leaks at sight glass and

filler plug. See Vacuum Leak Test.

5.

Vent kettle. See Kettle Venting Instructions for proper

procedure.

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

EN

T

A

IR

Remove

Pressure

Relief

Valve

Attach

Street

Elbow

Fill unit via Street Elbow

Important

-

Pull pressure relief valve

ring open to insure vessel

is not pressurized.

Sight

Glass