CLASSIC BLAST MACHINE with TLR-100/300 REMOTE CONTROLS

Page 23

© 2018 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 22501, Rev. I 02/18

could result in early valve failure or abrasive leakage

when the machine is pressurized or depressurized.

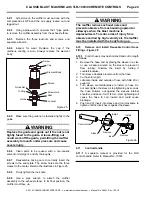

Figure

22

6.7.4

Slide the new pop-up valve over the guide and

then screw the valve guide (with the pop-up valve on it)

into position inside the machine. Tighten the guide

wrench-snug, but not wrench-tight. Over-tightening the

guide will make it difficult to remove the next time the

pop-up valve needs replacement.

6.7.5

Refer to Figure 23 to check the pop-up height. If

the pop-up sits too low, misalignment could occur when

the pop-up comes up against the seal. If the pop-up sits

too high, it will take longer for abrasive to flow through

the opening when filling. Adjust the height by replacing

the guide with one that is longer or shorter.

6.7.6

Put a new gasket on the inspection door before

bolting the door onto the machine.

Figure

23

6.8

Replacing the Pop-Up Seal - Figure 24

WARNING

To avoid serious injury from the sudden release

of compressed air, all service on the blast

machine must be done with the machine

depressurized, the air OFF, the air supply locked

out and tagged out, and the air-supply line bled.

6.8.1

Remove the old seal by using a finger,

screwdriver, or similar object to work the seal out of the

retainer groove. If for some reason replacement cannot

be made from the top of the machine, observe the

warning at the beginning of this section, and empty the

machine and bleed the air supply line. Remove the

inspection door assembly and work through the

inspection door opening.

Figure

24

6.8.2

Push the new seal all the way through the port

and then fit it into the retaining groove. For the last few

inches, pull up on the seal and allow it to pop into

position.

6.9

Exhaust Muffler - Figure 25

WARNING

Replace the muffler or element body as soon as

blast machine depressurization time increases

noticeably. Longer depressurization time

indicates the porous element body is becoming

clogged. If the element becomes plugged,

excessive air pressure could build up inside the

element and cause it to burst, resulting in injury.

Loosen

Tighten

Pop-Up Guide

Pop-Up Valve

Distance between the top of

the pop-up valve to the top of

the welding ring should be

1

1

/

2

min. and 2

1

/

2

max.

Pop-Up Guide

Seat Casting

Retainer Groove

Pop-Up Seat

Top of Blast Machine

Push into groove

Push or pull up to "pop"

it into the groove.

Welding Ring

Pop-Up Valve

1

1

/

2

- 2

1

/

2