9

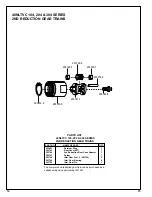

TRANSDUCER SPECIFICATIONS

MAXIMUM TORQUE CAPACITY

See full scale values below

OUTPUT VOLTAGE (Vo)

2 Millivolts per volt at maximum torque capacity

BRIDGE RESISTANCE (Rbr)

700 ohms (nominal) can be used with 350 and 700 ohm strain gage equipment*

TRANSDUCER CABLE

Cannon No. KPTO6AJ149P (mates with Cannon No. KPTO6AJ149S or equivalent)

CALIBRATION INSTRUCTIONS

CALIBRATION VALUES

GEAR TRAINS FULL SCALE VALUE

& ANGLE HEAD

FT. LBS.

Nm

104P

167.1

226.6

204P

178.3

241.8

304P

189.5

256.9

10M & K

40.0

54.2

20M & K

42.9

58.1

30M & K

45.5

61.7

In order to calculate the calibration value for the system in % full scale, the following formula may be used:

% FS = Rbr

1

1

------------------ X ----- X -----

2(Rcal) + Rbr Vo

2

Where Rcal = Calibration Resistor Value in ohms of the torque monitor used.

The following is an example of a 40 series right angle tool with a 10M gear train, angle head and a torque monitor with a

110,000 ohm calibration resistor.

The values are: FS = 40.0 ft. lbs.

Rbr = 700ohm

Vo = .002

Rcal = 110,000ohm

700ohm

1

1

% FS = --------------------------- X ------ X ----- = 79.3%

2(110,000ohm) + 700ohm .002

2

Calibration Value = 40.0 (.793) = 31.7 ft. lbs.

*Calculated calibration value should be doubled if a torque monitor designed for use with a 350ohm bridge resistance

transducer is used.

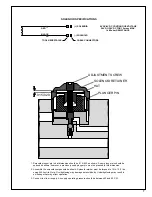

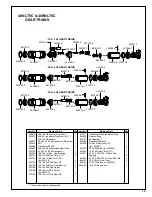

A

A

B

B

C

C

D

D

BLACK

GREEN

RED

WHITE

TOOL RECEPTACLE

CABLE CONNECTORS

R

WIRING DIAGRAM

E

E

F

F

(+) SIGNAL

(-) SIGNAL

SHIELD

(+) EXCITATION

(-) EXCITATION

Ro/2

Rm/2

R

R

R

t

C

t

C

Ro/2

Rm/2

Rcal

R= Gage Resistance

Rm= Modulus Resistor

Ro= Output Scaling Resistor

Rm & Ro may be omitted

Rcal= Shunt Calibration Resistor

NOTE: CALIBRATION VALUES MAY BE ADJUSTED TO

COMPENSATE FOR LOSSES THROUGH GEAR TRAINS

AND ANGLE HEADS.