5

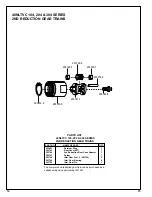

TRANSDUCER DISASSEMBLY

Remove the ring gear and transducer assembly from the rear

of the transducer housing. Press drive shaft No. 203703 or

203704, out of the transducer bearing No. 847566. Remove the

retainer ring No. 619017, from the transducer and tap lightly on

a soft surface to remove bearing, No. 847566. Drive the roll pin

No. 202888, into the transducer until it falls inside the trans-

ducer. Then remove the transducer from the rear of the ring

gear. Note: The transducer is a very delicate part and must be

handled very carefully.

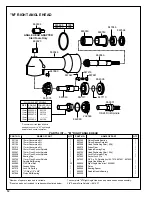

GEAR TRAIN DISASSEMBLY

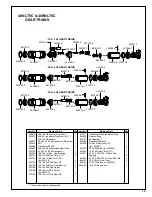

Single Reduction

The spider should be pressed out the rear of the gear case.

Remove the retainer ring, No. 844364, and press the bearing,

No. 847147, out the front of the gear case.

If replacement of the idler gear pins is necessary, they should

be pressed out the rear of the spider. See Fig. 1 for replacement

pin height.

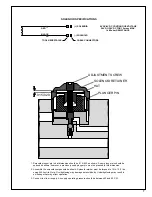

Fig. 1—Single Reduction Spider

Double Reduction

Both spiders should be removed from the rear of gear case.

Remove the retainer ring, No. 844364, and press the bearing, No.

847147, out the front of the gear case.

If replacement of the idler gear pins is necessary, they should

be pressed out the rear of the spider. See Fig .2 for replacement

pin height.

- 10 & - 104 2nd Reduction Spider - 10 & - 104

1st Reduction Spider

Fig. 2—Double Reduction Spiders

LIGHT RING KIT and HOUSING SHROUD DISASSEMBLY

Remove inlet bushing No. 203355, and slide back exhaust

deflector No. 203356. Unplug wiring and remove wire bundle

No. 203372. All caps and throttle lever must be removed from

backhead No. 203745 or No. 203979, before housing shroud

No. 203742 or 203982 and 203981, can be removed. Loosen

all three set screws No. 843518 and (2)No. 847282, in light ring

several turns. Slide housing shroud off the rear of the backhead.

NOTE: Do not rotate the light ring kit or housing shroud when

removing from backhead to prevent breaking wires. Hold pig

tail connection while removing light ring kit and housing shroud

from backhead.

SERVICE INSTRUCTIONS

DISASSEMBLY—GENERAL (ALL MODELS)

Disconnect tool from air supply. On the "M" and "K" head

unscrew (left hand threads) and remove the right angle head

and the angle head adapter No. 869034. On the "P" head

unscrew housing lock nut No. 203438, lift up and remove the

angle head. Unscrew and remove the second reduction gear

train. Unscrew the inlet bushing No. 203355 and lift exhaust

deflector far enough to unplug wire bundle No. 203372. Un-

screw valve caps(3) No. 203362, No. 832207 and No. 203360.

Remove throttle lever No. 867877. Remove throttle valve and all

related parts. Remove housing shroud or shrouds, from rear

of backhead, being very careful to prevent damage to the wiring.

Unscrew (left hand threads) transducer housing and lift care-

fully, feeding the wiring through the hole in the backhead. To

remove motor assembly, tap backhead lightly on a soft surface.

RIGHT ANGLE HEAD DISASSEMBLY

"K" Right Angle Head

To disassemble the right angle head, unscrew the spindle

bearing cap. This will permit the removal of the spindle assem-

bly.

The pinion bearing retainer No. 863564, may be removed by

utilizing a 5/8" hex nut and a 5/8" deep socket. Drop the hex nut

over the pinion shaft and engage the hex in the bearing retainer

and unscrew the retainer using the deep socket. Using a

suitable driver, drive the pinion No. 202200, and related bear-

ings out of the angle head.

"M" Right Angle Head

Using a suitable spanner wrench, unscrew (left hand threads)

the bearing cap No. 864396. Remove the spindle, ball bearing

No. 842517, and driven gear by clamping the spindle in a vise

and driving the right angle housing No. 869048, away from the

spindle using a soft-faced mallet. The ball bearing can now be

removed by pressing the larger end of the spindle through the

bearing I.D. Press the smaller end of the spindle through the

gear to remove the driven gear. The pinion bearing retainer No.

863564, may be removed by utilizing a 5/8" hex nut and a 5/8"

deep socket. Engage the hex in the bearing retainer and

unscrew the retainer using the 5/8" deep socket. The pinion and

bearings may now be removed by lightly tapping angle head on

a soft surface.

"P" Right Angle Head

Using a suitable wrench, unscrew (left hand threads) the

bearing cap, No. 203250. Remove the square drive spindle No.

203249 or No. 203439, ball bearing, No. 842517, and driven

gear No. 203251, by clamping the square drive in the vise. Drive

the right angle housing, No. 203441, away from the square

drive using a soft-faced mallet. Remove the spindle retainer

nut, No. 203248. The ball bearing can now be removed by

pressing the threaded end of the spindle through the gear to

remove the driven gear. Remove the housing set screw No.

867546, and using a punch, drive the pinion gear No. 203440,

and bearings No. 203253 and 202197 out the angle head.

.240

.255

Front

Rear

.360

.375

Front

Rear

.240

.255

Front

Rear