12

201102

201103

201104

201214

202566

202567

202568

202569

202725

842517

842980

843589

847219

847710

847846

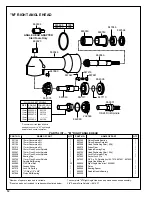

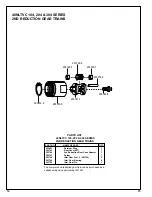

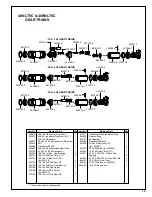

"M" RIGHT ANGLE HEAD

*Number of spacers required is variable.

**Denotes parts not included in subassemblies listed below.

The complete "M" Right Angle Head can be purchased as a subassembly.

3/8" Square Drive Spindle — 861637

PARTS LIST — "M" RIGHT ANGLE HEAD

PART NO.

PART NO.

NAME OF PART

NAME OF PART

QTY.

QTY.

863360

863564

863698

864076

864396

865723

867641

867642

867643

869034

869048

869049

869050

882629

10mm Conversion Kit

13mm Conversion Kit

15mm Conversion Kit

11mm Conversion Kit

10mm Flush Socket Spindle

13mm Flush Socket Spindle

15mm Flush Socket Spindle

Bearing Cap

11mm Flush Socket Spindle

Spindle Ball Bearing

3/32' Steel Ball

Grease Fitting

Lock Pin Spring

"O"-Ring 1/2" x 5/8"

Pinion Ball Bearing

Pinion Needle Bearing

Pinion Bearing Retainer

Head Positioning Shim (.008')

Driven Gear

Spindle Bearing Cap

Head Positioning Shim (.004')

Lock Pin Retainer Plug

Socket Lock Pin

3/8" Sq. Dr. Spindle (incl. 847219, 867641, 867642)

Angle Head Adapter

Right Angle Head (incl. 843589)

Pinion

Bearing Spacer

Spindle Needle Bearing

1

1

1

1

1

1

1

1

1

1

30

1

1

1

1

1

1

*

1

1

*

1

1

1

1

1

1

1

1

863564

869050

863360

847846

869048

869049

882629

864076

842517

847710

864396

867641

869034

ANGLE HEAD ADAPTER

Stall Tools Only

843589

867642

847219

867643

842980

202569

863698 .008"

865723 .004"

FLUSH SOCKET SPINDLE

SIZE SPINDLE CONVERSION

PART NO. KIT* PART NO.

10mm 202566-6 201102

11mm 202725-8 201214

13mm 202567-4 201103

14mm ------------ ------------

15mm 202568-2 201104

*Conversion kit contains all parts

needed to convert a "M" right angle

head to flush socket operation.

3/8-24 Drill Spindle

869051