CLEARSPAN

™

GREENHOUSES

20

Revision date: 10.03.14

Complete the following general steps to install the end wall

panels.

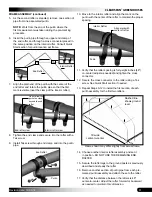

1. Consult the panel location diagrams, select one

polycarbonate panel, begin at the edge of the opening

for the door, and work to the outside edge of the end

wall.

See the X in the diagram below for the first panel.

END PANEL INSTALLATION (continued)

Mark UV Side

X

NOTE:

Remove the protective film. When needed, an

upper panel is cut to length

after

attaching it to the end

wall frame and rafter.

Always remove the protective film and mark and install

the UV-protected side to the outside of the greenhouse.

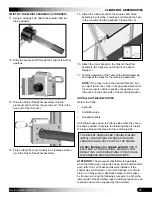

Photo shows Tek screw

and washer installed to

horizontal framing. Tek

screws and washers

are also used to secure

panels to the vertical

end framing.

H-channel

Installed End

Panels with

H-channel

DO NOT USE

WASHERS WHEN

SECURING THE

H-CHANNEL TO THE

END WALL FRAMING.

2. Apply white vent tape to the bottom of the lower panel

and then install the aluminum U-channel profile to the

edge of the panel adjacent to the door as shown on the

Polycarbonate Panels diagram.

EXCESS

Trimmed &

use here

Dashed line and small arrows (above) show where to

install the white vent tape. Do not install tape in any

other location on any other end panels.

X

Place the panel in position, attach it to the end wall

framing using Neo-bonded washers and the long Tek

screws. Space the screws evenly at 16" when securing

the panels.

Panel

Center

of tube

4' x 12' Panel

Not to scale.

The dotted line shows the location of the edge of the

first polycarbonate panel.

3. With the panel secured in place, cut it to the proper

size using the rafter as a guide.

NOTE:

DO NOT

damage the part of the polycarbonate

panel removed during the cutting of the panel. That

portion is used to cover the small area above the door.

The H-channel can be installed before the panel is

attached to the framing or after securing the panel to

the frame.

DO NOT install profile on the bottom of the end wall

panels.

These edges are sealed with the white vent

tape.

NOTE:

Tuck panel behind channel of the door frame.

Align the edge of the panel adjacent to the door with

the center of the vertical end wall frame tube that

frames the door.