ENGLISH

Operator’s Manual - Vantage 13

17

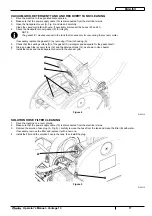

VACUUM GRID, DETERGENT TANK AND RECOVERY TANK CLEANING

Drive the machine to the appointed disposal area.

1.

Make sure that the power supply cable (10) is disconnected from the electrical mains.

2.

Open the transparent cover (A, Fig. 4) and clean it carefully.

3.

Clean the vacuum grid (B) with care. If necessary disconnect the hoses (20 and 21).

Check the transparent cover gasket (C) for integrity.

4.

NOTE

The gasket (C) creates vacuum in the tank that is necessary for vacuuming the recovery water.

If necessary replace the gasket (C) by removing it from its housing (A).

Check that the seating surface (D) of the gasket (C) is integral and adequate for the gasket itself.

5.

Drain and wash the recovery tank (16) and the detergent tank (14) as shown in Use chapter.

6.

Install the tanks and the transparent cover with the vacuum grid.

7.

A

B

D

C

Figure 4

P100315

SOLUTION HOSE FILTER CLEANING

Drive the machine on a level ground.

1.

Make sure that the power supply cable (10) is disconnected from the electrical mains.

2.

Remove the solution hose plug (A, Fig. 5), carefully remove the hose from the tank and clean the

fi

lter (B) with water.

3.

If necessary, remove the

fi

lter and replace it with a new one.

Install the

fi

lter and the solution hose in the tank, then install the plug.

4.

A

B

Figure 5

P100316

Summary of Contents for Vantage 13

Page 2: ......

Page 58: ...56 Parts List Vantage 13 1 6 4 11 10 2 2 5 3 7 8 4 9 9 9 TANKS SYSTEM...

Page 60: ...58 Parts List Vantage 13 1 2 5 6 3 8 7 2 4 2 9 4 10 FRAME UPPER SYSTEM 05 09...

Page 62: ...60 Parts List Vantage 13 1 5 8 6 7 10 10 5 5 9 4 2 3 11 FRAME LOWER SYSTEM 05 09...

Page 64: ...62 Parts List Vantage 13 1 2 6 10 8 7 6 5 4 6 3 9 3 9 3 TRANSMISSION SYSTEM...

Page 66: ...64 Parts List Vantage 13 4 1 2 3 3 BRUSHES SQUEEGEES DECK 05 09...

Page 68: ...66 Parts List Vantage 13 SUPPORT ROLLER KIT 05 09 1...

Page 70: ...68 Parts List Vantage 13 1 PANEL SYSTEM...

Page 72: ...70 Parts List Vantage 13 10 9 8 3 2 7 6 5 4 1 CARPET KIT OPTIONAL...

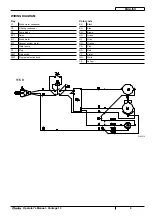

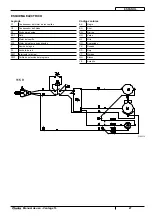

Page 74: ...72 Parts List Vantage 13 230 V 100 V 115 V 230 V 100 V 115 V WIRING DIAGRAM...

Page 76: ...74 Parts List Vantage 13 NOTES...