12

B. Milling

Vertical Milling is similar to drilling, except that instead of the workpiece being held stationary,

it may be moved in 3 directions - a. vertically, and b. horizontally in both axis. Milling cutters

are capable of cutting with their ends and their faces.

Several broad categories of end and face milling tools exist, such as centre cutting versus

non-centre cutting (whether the mill can take plunge cuts), and categorisation by number

of flutes, by helix angle, by material, and by coating material. Each category may be

further divided by specific application and special geometry.

Please note that It is not within the scope of this manual to advise on types of cutter, it is

assumed that the user is familiar with milling applications, cutters and techniques.

This machine is also capable of milling at any angle from vertical - 90º, to 45º left or right

of vertical.

Installing the Cutter

If the chuck is installed, proceed as follows:

1.

Insert the tommy bar into the hole in the side of the head so that it locates in the hole

in the spindle.

2.

Remove the draw bolt cover and with the spindle being held, undo the draw bolt by

two complete turns only, using the spanner provided.

3.

Strike the head of the draw bolt sharply with a soft faced mallet, or by placing a

piece of wood on the head and striking the wood with a hammer. The taper shank

will disengage, thereby allowing the draw bolt to be fully unscrewed and the drill

chuck and taper shank to be withdrawn.

NOTE: It is possible that when the head of the draw bolt is struck, the chuck could become

disengaged with the taper shank and drop on to the bed, with possible resultant damage.

It is strongly advised therefore, that the operator holds the chuck with one hand whilst

striking the head of the draw bolt, or a substantial piece of cloth is placed beneath the

chuck, in order to avoid damage when it drops.

With the taper shank removed, the cutter may be installed in a similar manner to the drill

chuck, please see the notes on pages 10/11.

Please note that a range of accessories, including collet sets and collet chuck sets which are used

to secure the cutter, are available from your Clarke dealer - see Accessories on page s 20/21.

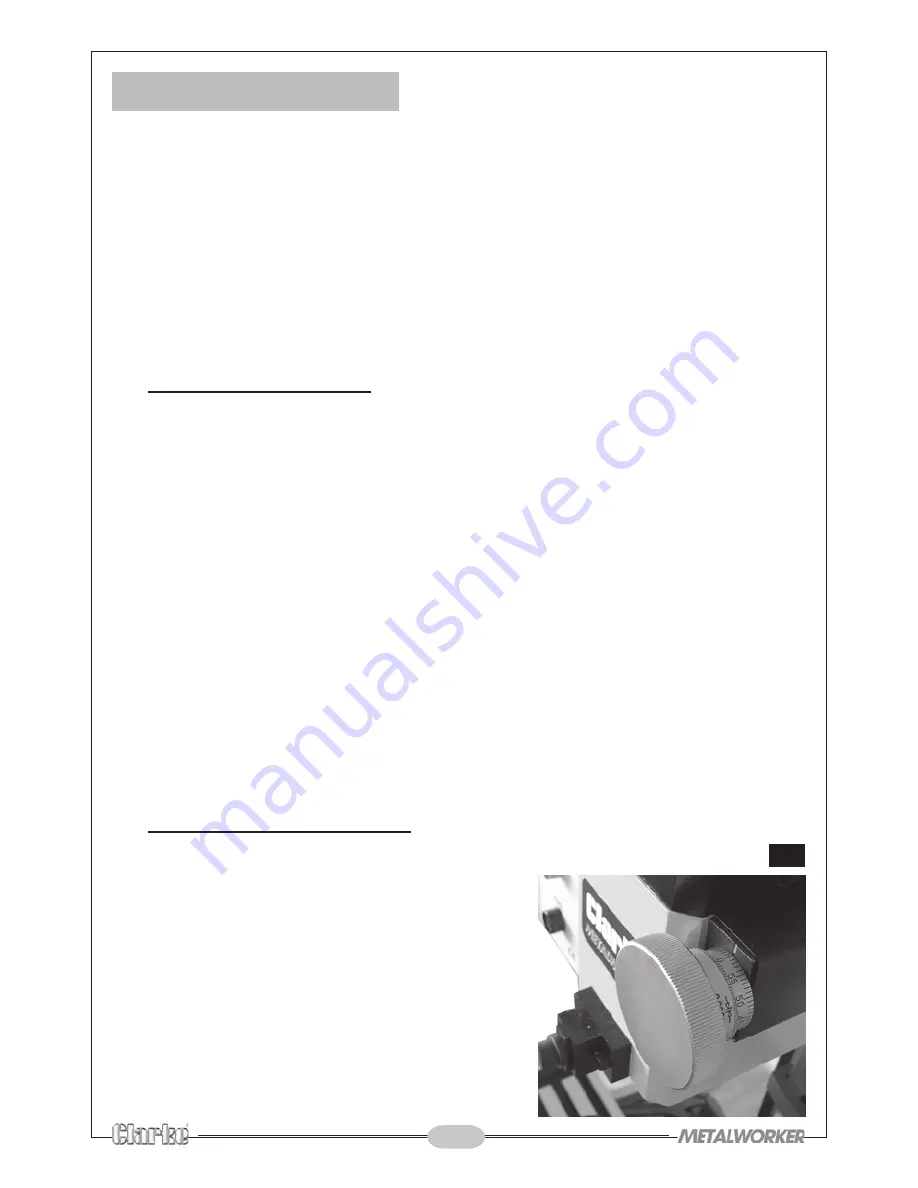

Using the Micro Feed

17

For Milling, the micro feed should always be used.

In order to use this device, it is first of all necessary to

engage the dog clutch on the raise/lower hub

assembly. Simply turn the raise/lower handles until the

cutter is as near the workpiece as possible and the

dogs become aligned, then push the hub IN fully.

In this mode, the handles cannot be used to raise or

lower the head, only by turning the micro adjuster

knob, will this be effected.

A scale on the adjuster sleeve may be used to

determine the depth of cut.

Turn the adjuster so that the cutter just touches the

workpiece, then zero the scale by holding the adjuster

Fig.8

Summary of Contents for CMD300

Page 8: ...8 Parts Identification FIG A FIG B FIG C ...

Page 15: ...15 Parts Diagram ...

Page 16: ...16 Parts Diagram ...

Page 23: ...23 ...

Page 24: ......