9

installation:

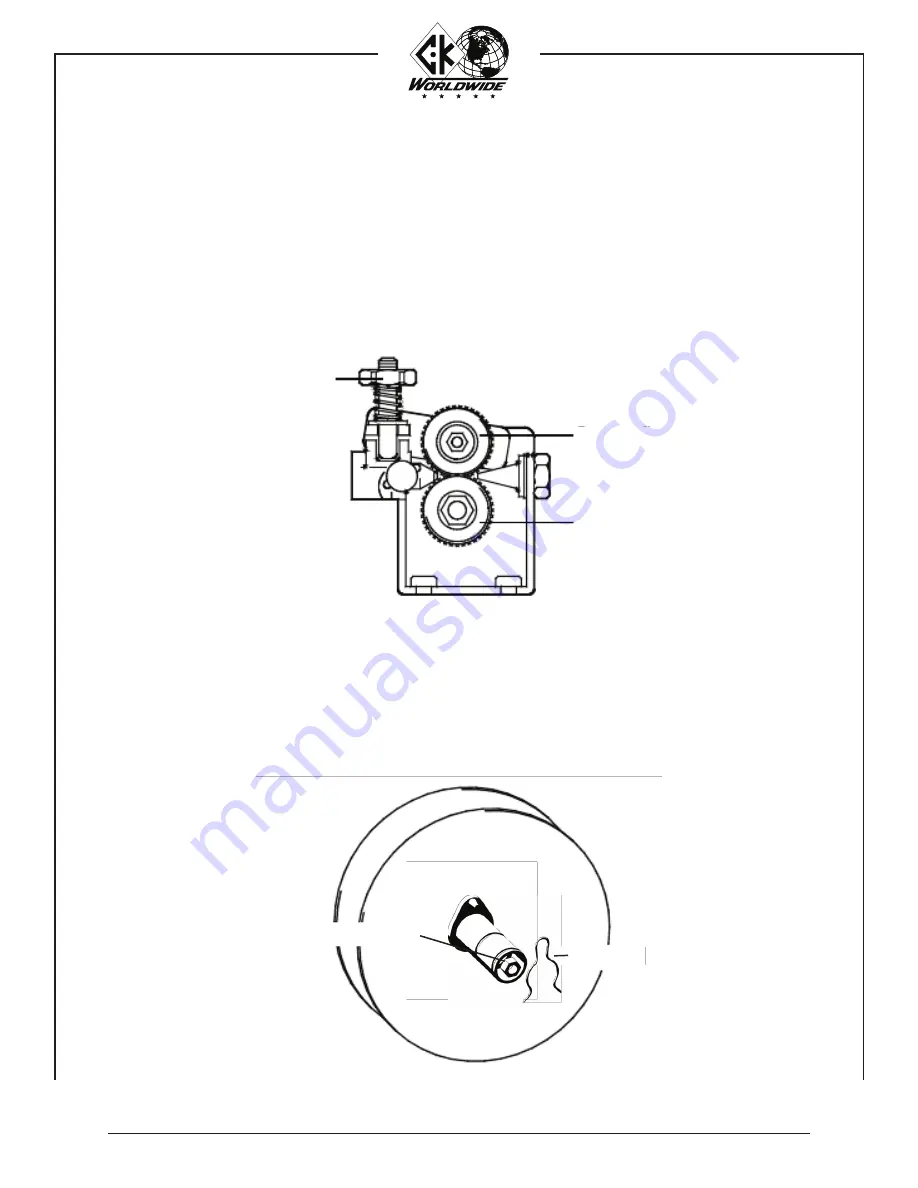

Wire feed roll adjUstMent:

spool Brake adjUstMent:

to adjust the feed rolls, tighten the pressure roll adjusting nut

approximately one-half turn past the point where the rolls

just begin to “grab” the welding wire.

too much braking force will needlessly overload the drive

motor.

always replace and lock the cover door after loading wire.

feed rolls that are adjusted too tightly will result in deformed

wire and needless overload of the drive motor.

iMportant:

Warning:

note:

Warning:

8. the wire feed rolls and spool brake are properly adjusted at the factory, prior to delivery. as

componenets “seat in”, it may be necessary to adjust the settings.

9.

adjust the spool brake by turning the brake adjusting nut in to increase braking force and oUt

to decrease the braking force. adjust the brake just tight enough to prevent the welding wire

from over-running when feeding has stopped.

pressure roll

adjusting nut

pressure roll

drive roll

retaining clip - cW804

spool Brake adjusting nut