Service setups

HS Series 2K Service Manual—D13HD2-HS, D13WU2-HS, D16HD-HS, D16WU-HS, D20HD-HS, D20WU-HS

27

020-001468-02 Rev. 1 (01-2020)

Copyright ©2020 Christie Digital Systems USA Inc. All rights reserved.

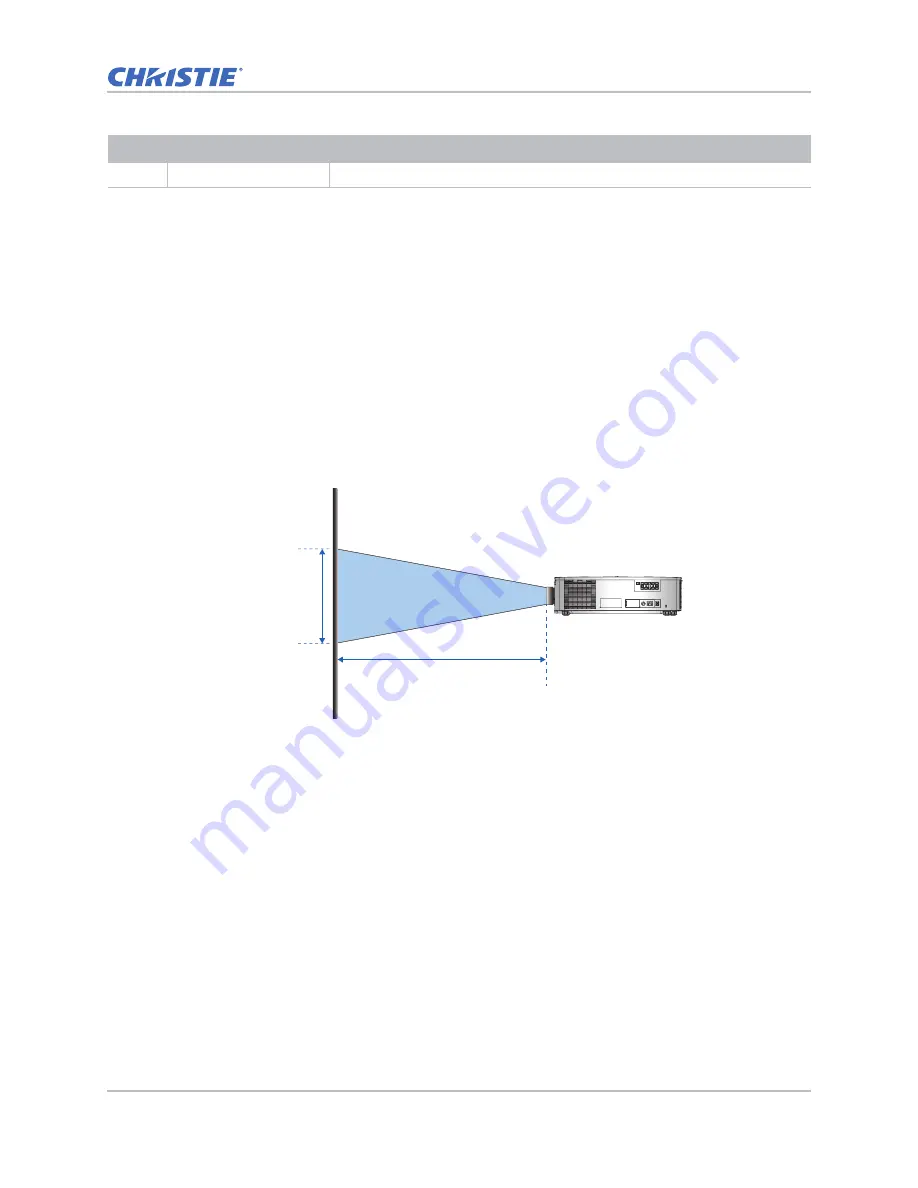

Adjusting the back focus

To set up for the back focus adjustment, follow the steps below.

1. Use the PC to project a

Full Screen

test pattern.

2. Adjust the lens zoom to its widest position.

3. Adjust the focus to make the picture as fuzzy as possible.

4. Measure and confirm the minimum imaging values are differ less than 3 cm from the lens

specification values.

• If the value does not meet the lens specification within 3 cm, adjust the three set screws

with a M4 Allen key.

• If the value does meet the lens specification, perform a bore-sight adjustment.

3

Criteria

• The image is clear, crisp, and sharp.

ID

Part name

Description

FUSE T15A/250V~

200V-240V~

Focus

Point

Distance

Summary of Contents for D13HD2-HS

Page 107: ......