K4W120-210-310

Installation Instructions

8

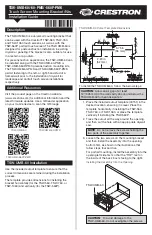

Install Arm Assembly to Wall

-

Hollow

Concrete Block or Poured Concrete

WARNING:

Failure to provide adequate structural strength

for this component can result in serious personal injury or

damage to equipment! It is the installer’s responsibility to

make sure the structure to which this component is attached

can support five times the combined weight of all equipment.

Reinforce the structure as required before installing the

component.

WARNING:

The wall to which the mount is being attached

may have a maximum drywall thickness of 5/8” (1.6cm). Do

not install drywall anchors into the seam between drywall

pieces.

WARNING:

INSTALLING A K4W SERIES MOUNT INTO

UNDERRATED OR DAMAGED CONCRETE CAN LEAD TO

SERIOUS INJURY OR DAMAGE TO PRODUCT! Never

install a K4W Series mount into cracked, chipped or flaking

concrete.

1.

Determine mounting location.

2.

Measure 1" above desired center line and mark a hole at

desired mounting location. (See Figure 3)

IMPORTANT ! :

Use a level to make sure arm assembly

(Z) is level when mounted to the wall!

IMPORTANT ! :

The K4W Series mounts are designed to be

mounted to an 8" concrete or 8"x 8"x 16" concrete block wall.

3.

Drill one 5/16” diameter hole at location marked in Step 2

with a depth of 3 1/4”. (See Figure 3)

Figure 3

4.

Install one concrete anchor (C) into drilled hole. (See Figure

3)

5.

Install one 1/4 x 2 1/2” lag bolt (B) into concrete anchor (C),

leaving bolt hanging out 1/2” from the wall. (See Figure 3)

6.

Hang arm assembly (Z) onto lag bolt (B) by latching key-

shaped hole over top of bolt. (See Figure 3)

7.

Mark two holes at lower mounting hole locations. (See

Figure 4)

8.

Remove arm assembly (Z) from wall.

9.

Drill two 5/16” holes at marked locations. (See Figure 4)

10. Install two concrete anchors (C) into holes. (See Figure 4)

11. Hang arm assembly (Z) back onto wall.

12. Install two 1/4 x 2 1/2” lag bolts (B) into concrete anchors (C)

to secure mount to wall. (See Figure 4)

13. Tighten all lag bolts (B) to fully secure mount to wall.

Figure 4

(B)

6

1/2”

screen

center

1" above

2

3

5/16”

center

5

4

(C)

(B)

(C)

(B) x 2

12

7

9

10

(C) x 2

5/16"

8

11

(remove mount)

(hang mount)