LT-WIC101010

3

rd

Printing

Page 13 of 16

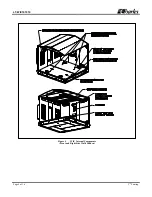

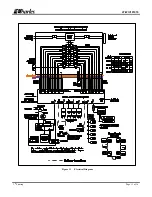

The right side of the WIC, near the top, has two panels, each with four portals. Each portal has nine Ø0.605” entry ports athat

accommodate Ø0.5” cable.

See Figures 2, 3, and 4 for all entry locations.

3.8.

Conduit Seals

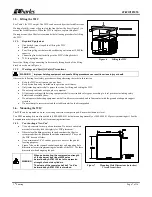

All conduit openings on the WIC must be completely sealed with a duct seal compound to prevent

moisture from entering the WIC. Use a moldable, flame-retardant putty style duct seal material. Do not

use an expanding foam seal. Mold the putty so that the open space around the wire or conduit is

completely sealed, as shown in Figure 12. If the openings must be accessed at any time, remove the

putty and set it aside. When work is complete, re-mold the putty to re-seal the opening.

3.9.

Verifying the Installation

Verify that earth ground and all grounding and bonding is complete and functional. After verifying that

all installer connections are secure and complete, apply voltage.

4.

PERIODIC MAINTENANCE

In the event that the enclosure must be opened in freezing conditions, use a narrow, pointed metallic object such as a screwdriver or chisel,

along with a non-metallic device like a rubber mallet, to remove excessive ice buildup around the door and locking mechanism. A

commercial aerosol de-icer spray can be used to free up locks and latches if needed. Use protective gloves and safety glasses when

applying de-icer sprays.

Reset the GFCI duplex receptacle periodically to ensure it is working. The unit meets UL-943, which requires an auto-monitoring (self-

testing) feature. A flashing or solid red LED indicates a fault. If the unit continues to show a fault after resetting, replace the unit.

Refer to the CTMS manual supplied with the CTMS for periodic maintenance requirements.

5.

TECHNICAL ASSISTANCE AND REPAIR SERVICE

For questions on product repair or if technical assistance is required, contact Charles Technical Support.

847-806-8500

http://www.charlesindustries.com/techserv.htm

6.

WARRANTY & CUSTOMER SERVICE

Charles Industries LLC offers a one-year warranty on the WIC product. The Charles warranty is limited to the operation of the WIC

hardware as described in this documentation and does not cover equipment which may be integrated by a third party. The terms and

conditions applicable to any specific sale of product shall be defined in the resulting sales contract. For questions on warranty or other

customer service assistance, contact your Charles Customer Service Representative.

847-806-6300

http://www.charlesindustries.com/main/telecom_sales_support.htm

7.

SPECIFICATIONS

7.1.

Regulatory Specifications

Designed to meet GR-487

UL-60950 Recognized

GFCI: UL-943 Listed

If WICs are field-modified, a customer provided ETL field evaluation of the modified components may be required to re-establish ETL

certification to UL standards. Consult local jurisdictions for guidance on a site-by-site basis.

Figure 12

Applying Putty Seal