4

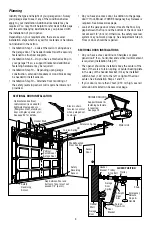

SECTIONAL DOOR INSTALLATION

Planning

Identify the type and height of your garage door. Survey

your garage area to see if any of the conditions below

apply to your installation. Additional materials may be

required. You may fi nd it helpful to refer back to this page

and the accompanying illustrations as you proceed with

the installation of your opener.

Depending on your requirements, there are several

installation steps which may call for materials or hardware

not included in the carton.

• Installation Step 1 – Look at the wall or ceiling above

the garage door. The header bracket must be securely

fastened to structural supports.

• Installation Step 5 – Do you have a fi nished ceiling in

your garage? If so, a support bracket and additional

fastening hardware may be required.

• Installation Step 10 – Depending upon garage

construction, extension brackets or wood blocks may

be needed to install sensors.

• Installation Step 10 – Alternate fl oor mounting of

the safety reversing sensor will require hardware not

provided.

• Do you have an access door in addition to the garage

door? If not, Model 7702CB Emergency Key Release is

required. See Accessories page.

• Look at the garage door where it meets the fl oor. Any

gap between the fl oor and the bottom of the door must

not exceed 1/4" (6 mm). Otherwise, the safety reversal

system may not work properly. See Adjustment Step 3.

Floor or door should be repaired.

SECTIONAL DOOR INSTALLATIONS

• Do you have a steel, aluminum, fi berglass or glass

panel door? If so, horizontal and vertical reinforce ment

is required (Installation Step 11).

• The opener should be installed above the center of the

door. If there is a torsion spring or center bearing plate

in the way of the header bracket, it may be installed

within 4 feet (1.22 m) to the left or right of the door

center. See Installation Steps 1 and 11.

• If your door is more than 7 feet (2.13 m) high, see rail

extension kits listed on Accessories page.

FINISHED CEILING

Horizontal and vertical

reinforcement is needed for

lightweight garage doors

(fi berglass, steel, aluminum,

door with glass panels, etc.).

See page 23 for details.

Slack in chain

tension is normal

when garage door

is closed.

Support bracket &

fastening hardware

is required.

See page 15.

Extension Spring

Motor Unit

OR

Torsion Spring

Header Wall

Vertical

Centerline of

Garage Door

Wall-Mounted

Door Control

Access

Door

Safety

Reversing

Sensor

Safety

Reversing

Sensor

Gap between fl oor and

bottom of door must not

exceed 1/4" (6 mm).

Trolley

Header

Bracket

Garage

Door

Spring

Chain

Emergency

Release

Rope &

Handle

Straight

Door

Arm

Curved

Door Arm

Door

Bracket

Header

Wall

Garage

Door

Trolley

Stop Bolt

CLOSED POSITION