2 . INTRODUCTION - SAFETY INSTRUCTIONS AND WARRANTY

2.12

2.16.4 - Follow recommended start-up procedures

Follow the start-up procedures recommended in the Oper-

ation chapter of this Operator instruction Book. This chap-

ter includes normal starting, cold starting, and the use of

starting fluids.

2.16.5 - Controls test

After starting, check all gauges and lights again. Make sure

everything is functioning correctly. If the tractor does not

respond correctly when each control is operated,

DO NOT

USE

the machine until the fault is remedied.

Ensure that the starter solenoid cover is always in position.

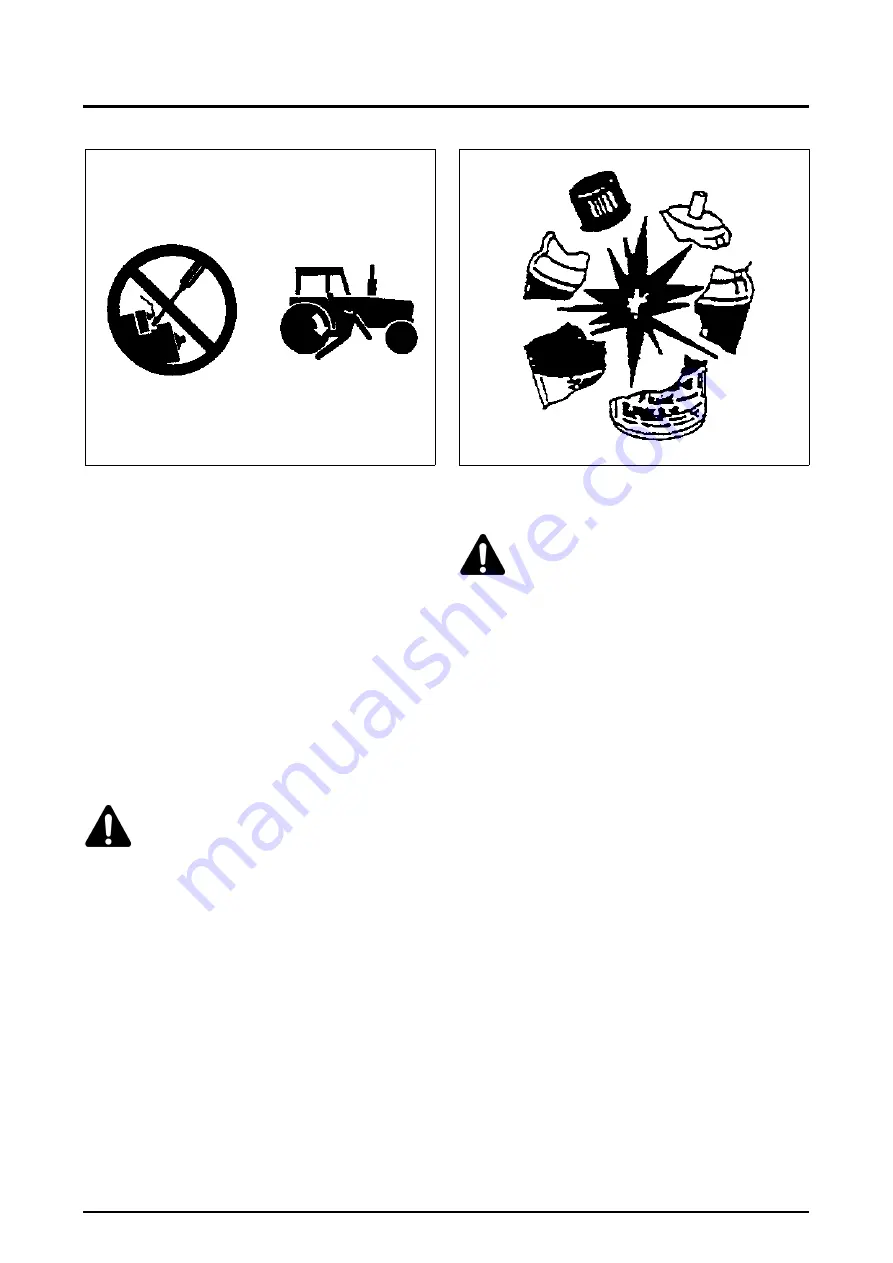

2.16.6 - Starting fluid

WARNING: It is very important that you read

and follow the starter fluid instructions before

using it. DO NOT use aerosol cans of starter

fluid on tractors with the thermostat con-

nected to the electrical system. Ether combined with

thermostat can cause an explosion with damage to

engine, personal injury, or both.

Handle starting fluid correctly. Starting fluid must only be

used in conjunction with an ether-start aid fitted as original

equipment by the manufacturer or installed by a Dealer as

an accessory. In cases of tractors being fitted with glow

plugs or a thermostat, these must be removed prior to the

installation of an ether-start aid (Fig. 9).

If aerosol cans of starting fluid are to be used the thermo-

stat must be disconnected. Remove the wire from the

thermostat which will be found on the manifold. Tape the

end of the wire to prevent an electrical short circuit.

2.17 - WORKING SAFELY

WARNING: An unbalanced tractor could over-

turn and cause injury or death.

Make sure front frame counterweights, wheel

weights and wheel ballast are used as recom-

mended by the manufacturer. DO NOT add extra coun-

terweights to compensate for an overloaded tractor; it

is recommended to reduce the load. Keep all parts of

your body inside the cab while operating the tractor.

2.17.1 - Make the right moves

Ensure that the tractor is ready for the work to be carried

out. Make sure you know the tractor nominal load capaci-

ties and never exceed them. Be certain that any attach-

ments or implements you intend to use

DO NOT EXCEED

the load rating of your tractor. Be sure the tractor and im-

plement PTO speed match.

Keep in mind that tractors normally operate on uneven, un-

paved, and often bumpy or sloping surfaces. Operating

conditions can reduce the amount of weight you should

carry or pull.

2.17.2 - Safety instructions to be observed

• Operate the controls smoothly - don’t jerk the steering

wheel or other controls.

•

NEVER

get on or off a moving tractor. Keep a firm grip

on the steering wheel at all times, with the thumbs clear

of the spokes when driving the tractor.

• Make sure you have adequate clearance in all directions

for the tractor and implement.

•

DO NOT

play with a tractor or equipment. Use only for

intended purpose.

•

DO NOT

attempt to work the controls except from the

driver’s seat.

Z2-535-05-03

Fig. 8

Fig. 9

WC1952

Summary of Contents for Techstar CVT MT525B Series

Page 2: ......

Page 4: ......

Page 5: ...1 TRACTOR IDENTIFICATION 1 1 Challenger MT500B EU 1 Chapter 1 TRACTOR IDENTIFICATION ...

Page 6: ......

Page 7: ...1 TRACTOR IDENTIFICATION 1 3 Challenger MT500B EU 1 CONTENTS 1 1 SERIAL NUMBERS 1 5 ...

Page 8: ...1 TRACTOR IDENTIFICATION 1 4 Challenger MT500B EU ...

Page 12: ......

Page 30: ......

Page 31: ...3 INSTRUMENTS AND CONTROLS 3 1 Challenger MT500B EU 3 Chapter 3 INSTRUMENTS AND CONTROLS ...

Page 32: ......

Page 34: ...3 INSTRUMENTS AND CONTROLS 3 4 Challenger MT500B EU ...

Page 51: ...4 OPERATION 4 1 Challenger MT500B EU 4 Chapter 4 OPERATION ...

Page 52: ......

Page 90: ......

Page 124: ......

Page 125: ...6 SPECIFICATIONS 6 1 Challenger MT500B EU 6 Chapter 6 SPECIFICATIONS ...

Page 126: ......

Page 128: ...6 SPECIFICATIONS 6 4 Challenger MT500B EU ...

Page 138: ......

Page 139: ...7 ACCESSORIES AND OPTIONS 7 1 Challenger MT500B EU 7 Chapter 7 ACCESSORIES AND OPTIONS ...

Page 140: ......

Page 235: ...8 TROUBLESHOOTING 8 1 Challenger MT500B EU 8 Chapter 8 TROUBLESHOOTING ...

Page 236: ......

Page 238: ...8 TROUBLESHOOTING 8 4 Challenger MT500B EU ...

Page 242: ......

Page 243: ...CONVERSION TABLES Challenger MT500B EU Appendix CONVERSION TABLES ...

Page 244: ......

Page 246: ......