8

NORSE Operating Manual & Parts List 9681310 & 9681311

urn the pointer from the middle OFF position to the left

T

3.

urn the pointer from the middle OFF position to the left

urn the pointer from the middle OFF position to the left

Setting the miter tool to a 90º right angle

Setting the miter tool to a 90º right angle

g

It is recommended that you sand your workpiece with the disc

Setting the

hand or knee.

position, or push the emergency stop button with either your

o stop the machine, turn the pointer back the middle OFF

T

To stop the machine, turn the pointer back the middle OFF

5.

direction.

The right REV position will rotate the disc in the clockwise

4.

motion.

FOR position, and the disc will spin in the counter-clockwise

g

It is recommended that you sand your workpiece with the disc

e guards for forward or reverse rotation

hand or knee.

position, or push the emergency stop button with either your

o stop the machine, turn the pointer back the middle OFF

direction.

The right REV position will rotate the disc in the clockwise

FOR position, and the disc will spin in the counter-clockwise

urn the pointer from the middle OFF position to the left

It is recommended that you sand your workpiece with the disc

verse rotation

position, or push the emergency stop button with either your

o stop the machine, turn the pointer back the middle OFF

The right REV position will rotate the disc in the clockwise

FOR position, and the disc will spin in the counter-clockwise

g

Use a machinist square or suitable tool and adjust the face

2.

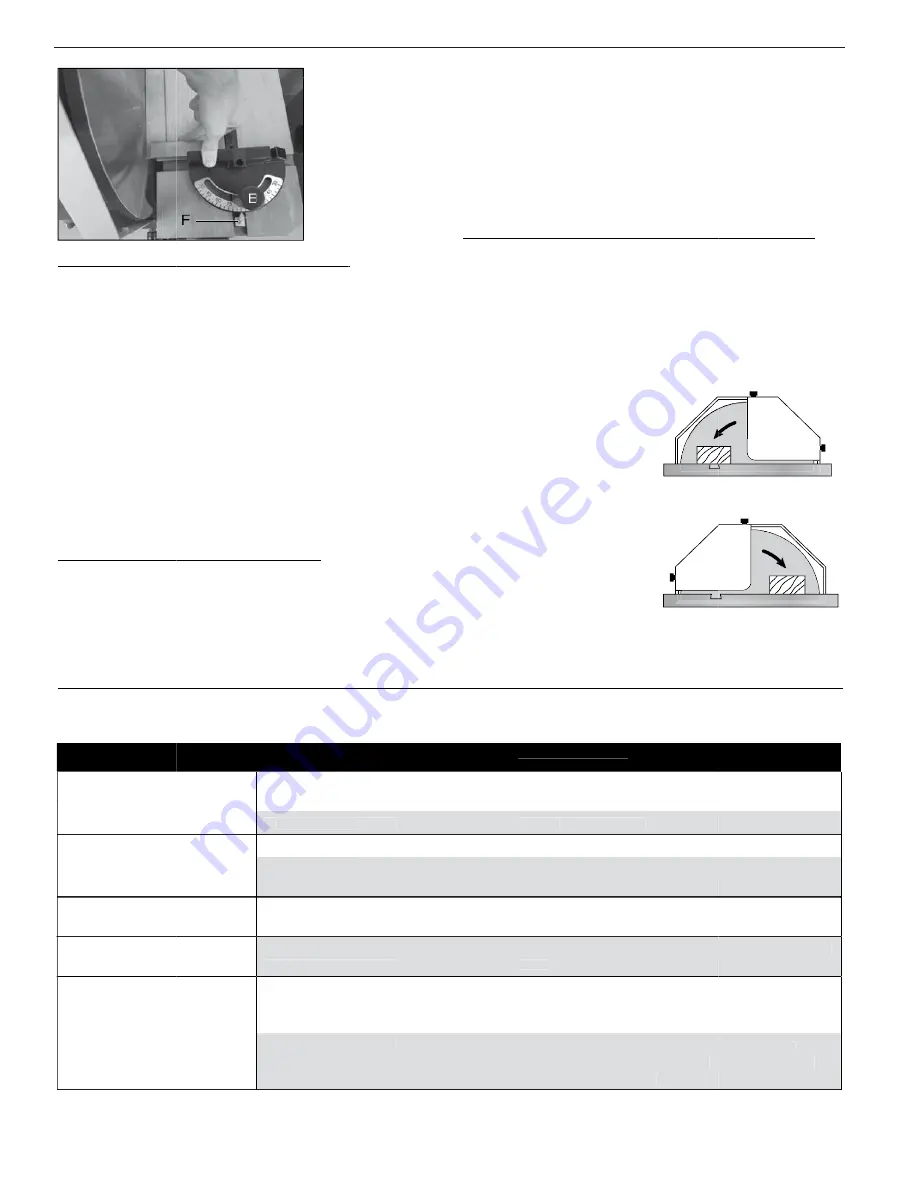

Slightly loosen the miter tool adjustment push knob (E).

1.

tool while the abrasive sanding disc is removed.

While not required, it is much easier to adjust the miter

NOTE:

steps:

o set a true 90º refe

T

To set a true 90º reference for miter tool, perform the following

performs accurate flush and angled miter sanding operations.

The miter tool can be adjusted to ensure your disc sander

Setting the miter

g

g

Use a machinist square or suitable tool and adjust the face

Slightly loosen the miter tool adjustment push knob (E).

tool while the abrasive sanding disc is removed.

While not required, it is much easier to adjust the miter

o set a true 90º reference for miter tool, perform the following

performs accurate flush and angled miter sanding operations.

The miter tool can be adjusted to ensure your disc sander

r tool to a 90º right angle

Use a machinist square or suitable tool and adjust the face

Slightly loosen the miter tool adjustment push knob (E).

While not required, it is much easier to adjust the miter

o set a true 90º reference for miter tool, perform the following

performs accurate flush and angled miter sanding operations.

The miter tool can be adjusted to ensure your disc sander

according to the rotation of the sanding disc.

depending on the guard’

and removing the two black knobs on the top and back (or front

rear half of the sanding disc. Move the top guard by loosening

The top disc guard can be moved to expose either the front or

rotating down toward the workpiece to hold it against the table.

It is recommended that you sand your workpiece with the disc

o set up the machine for

T

To set up the machine for

rotation set up

Counterclockwise

according to the rotation of the sanding disc.

The guard’

s set up).

depending on the guard’

and removing the two black knobs on the top and back (or front

rear half of the sanding disc. Move the top guard by loosening

The top disc guard can be moved to expose either the front or

rotating down toward the workpiece to hold it against the table.

It is recommended that you sand your workpiece with the disc

o set up the machine for

rotation set up

Counterclockwise

Front

Machine

s position is set

The guard’

and removing the two black knobs on the top and back (or front

rear half of the sanding disc. Move the top guard by loosening

The top disc guard can be moved to expose either the front or

rotating down toward the workpiece to hold it against the table.

It is recommended that you sand your workpiece with the disc

g

out.

, and the emergency stop button is pulled

electrical supply

Ensure the machine is properly connected to a suitable

1.

Turning on the sa

Adjust the indicator pointer (F) to 90º if required.

4.

miter tool to ensure it is square.

Carefully tighten the adjustment push knob and recheck the

3.

tool face and flywheel disc.

of the miter tool until the square rests flush on both the miter

g

, and the emergency stop button is pulled

Ensure the machine is properly connected to a suitable

anding disc machine

Adjust the indicator pointer (F) to 90º if required.

miter tool to ensure it is square.

Carefully tighten the adjustment push knob and recheck the

tool face and flywheel disc.

of the miter tool until the square rests flush on both the miter

, and the emergency stop button is pulled

Ensure the machine is properly connected to a suitable

Adjust the indicator pointer (F) to 90º if required.

Carefully tighten the adjustment push knob and recheck the

of the miter tool until the square rests flush on both the miter

portion of the disc.

set the disc guard to the back

counterclockwise rotation,

o set up the machine for

T

To set up the machine for

the back portion of the disc.

guard to the front and sand on

clockwise rotation set the disc

o set up the machine for

T

To set up the machine for

Clockwise rotation set up

portion of the disc.

set the disc guard to the back

counterclockwise rotation,

o set up the machine for

Front

Machine

the back portion of the disc.

guard to the front and sand on

clockwise rotation set the disc

o set up the machine for

Clockwise rotation set up

emergency stop button.

Locate the power and direction switch to the left of the

2.

TROUBLESHOOTING GUIDE

Symptom

Sanding paper becomes glazed.

emergency stop button.

Locate the power and direction switch to the left of the

TROUBLESHOOTING GUIDE

Possible Cause(s)

Sanding paper becomes glazed. Sanding a painted or coated surface.

Locate the power and direction switch to the left of the

Corrective Action

grit.

Use open-end grain/flint sanding paper with a coarser

Sanding a painted or coated surface.

Possible Cause(s)

Corrective Action

Use open-end grain/flint sanding paper with a coarser

Use open-end grain/flint sanding paper with a coarser

orkpiece pulled fro

W

Workpiece pulled from hand.

.

quickly

Sanding paper burns, or clogs

Burn marks on workpiece.

orkpiece pulled from hand.

Allow the disc to cut freely

hand sand workpieces.

No support for workpiece. Do not free

disc.

Sanding paper burns, or clogs

disc.

Do not force the workpiece into sanding

rong sanding paper surface.

Burn marks on workpiece.

Forcing the workpiece into the sanding

ood is wet or g

W

W

Wood is wet or gummy

amounts of material in one pass.

table.

Use miter gauge. Keep workpiece firmly down against

hand sand workpieces.

No support for workpiece. Do not free

the disc to cut freely

Make several passes instead of trying to remove large

.

Allow the disc to cut freely

Do not force the workpiece into sanding

Use coarser grit for stock removal.

Do not force the workpiece into sanding disc.

Forcing the workpiece into the sanding

Use dif

rong sanding paper surface.

grit.

.

ood is wet or gummy

amounts of material in one pass.

table.

Use miter gauge. Keep workpiece firmly down against

.

Make several passes instead of trying to remove large

Use coarser grit for stock removal.

the disc to cut freely

Do not force the workpiece into sanding disc.

ferent material.

grit.

e dif

fferent material.

Make several passes instead of trying to remove large

Use miter gauge. Keep workpiece firmly down against

Allow

Do not force the workpiece into sanding disc.

8

Sanded edge is not square.

Sanded edge is not square.

sanding is not recommended.

able scale inacc

T

Table scale inaccurate.

Result of freehand sanding. Free hand

workpiece is square with sanding disc.

table angle if necessary

square. It should be 90 degrees.

Check table alignment to disc with a machinist’

able scale inaccurate.

square edge is desired. Use miter gauge to ensure

Keep workpiece flat on table at all times when a

sanding is not recommended.

Result of freehand sanding. Free hand

workpiece is square with sanding disc.

.

table angle if necessary

Adjust pointer and

square. It should be 90 degrees.

Check table alignment to disc with a machinist’

square edge is desired. Use miter gauge to ensure

Keep workpiece flat on table at all times when a

workpiece is square with sanding disc.

Adjust pointer and

s

Check table alignment to disc with a machinist’

square edge is desired. Use miter gauge to ensure

Keep workpiece flat on table at all times when a