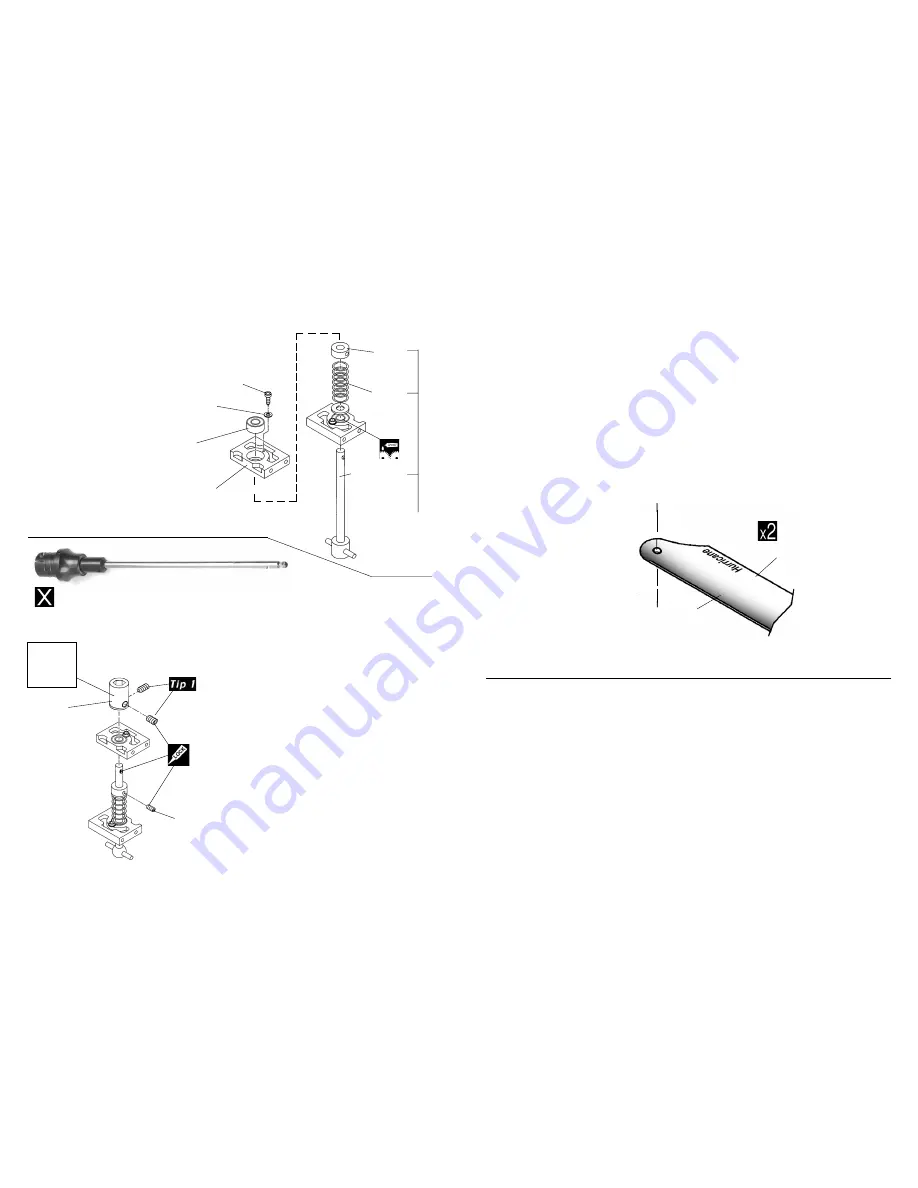

From parts bag 2: The

Start Shaft Guide Blocks

are pre-assembled. Slide

the Starter Shaft through

one of the block assem-

blies with the M5x11 Ball

Bearing facing up then

slide the M5 Flat Washer,

spring and finally the

M5x10 Collar.

M5x10

Collar

M2x5 Self

Tapping Screw

Spring

M2x5 Flat

Washer

5x11 Ball

Bearing x 2

[CNBB1150]

Start Shaft Guide

Blocks x 2

[HI3007]

Starter Shaft

Set

[HW3005A]

Step 9

Starting Shaft Bearing Blocks

Step 10 Starting Shaft & Hex Coupler

From parts in bag 2: After sliding the top bear-

ing block in place, attach the hex starter adapter

CN0402 to the starting shaft using threadlock on

both 4x4mm set screws. Align one set screw to fit

into the machined indentation in the hardened

start shaft. For added strength apply a locktight

to the shaft before the hex coupler is attached.

Apply some lubricant on the shaft after assembly

to ensure smooth vertical movement inside the

inner races of the bearings when engaging and

disengaging the start system. Position the M5

collar so the end of the start shaft clears the fan,

verify after installing the lower frames.

Hex Start

Adapter

[CN0402]

M4x4 Set

Screw x 2

(med hex key)

Optional:

Aluminum

Start Cone

#CN2209

3x4mm Set

Screw

(small hex key)

When removing the hex start extension after

the engine has started, it is recommended that

you use a two step procedure.

Step #1: Lift the hex extension upwards just

enough to disengage the start shaft while

keeping the extension inserted in the hex

coupler (CN0402).

Step #2: After the coupler has stopped turning,

then remove the extension completely.

Engine Start Procedure with Hex Coupler

Starter Shaft

One way Hex Starter Extension

(Optional Part #CN0427)

35

The Main Rotor Blades included in

Raven 50

the kit are pre-finished and balanced carbon rotor blades. Care

must be taken in handling composite blades to keep them in excellent condition. Do not compress any portion

of the blade from the trailing edge to the center spar as it is hollow. In the event of a crash-landing discard rotor

blades, scuffs or marks on the blade tips maybe the only visible damage however there is no method for inspect-

ing the internal structure of the rotor blades for stress cracks which can cause total blade failure at an unpredict-

able time. Also, do not store rotor blades indoors in direct sunlight or near heat sources for any period of time.

Simply wipe blades clean after flying.

Blades rotate clockwise, so observe the leading edge. To install the blades, slide the root into the rotor grip

and insert one 4x30mm Socket Cap Screw through the top grip and secure using one 4mm Locknut. Repeat for

opposite rotor blade. Blade bolt tension will affect how the blades perform. To set proper tension, start from

loose blades (bolt is loose enough for the blade to pivot freely from the grip) and tighten the bolts a little at a

time until the blades will hold straight as the helicopter is tipped on its side. Slightly tighter is good. Too tight

and a vibration will occur, too loose and a tail boom strike can happen. Tail blades can be set the same way.

Trailing Edge

of Blade

Leading Edge

of Blade

Raven 30

CN2400

Hurricane Carbon 3D Symmetrical 550mm

CN2414

Hurricane Carbon Sport Semi-Symm 550mm

CN265501

Rotortech Carbon 3D Competition Symmetrical 550mm

CN265522

Rotortech Carbon 3D Sport Symmetrical 550mm

CN260853

Rotortech Carbon Tail Blades Symmetrical 85mm

Raven 50

CN2412

Hurricane Carbon 3D Symmetrical 600mm

CN2413

Hurricane Carbon Sport Semi-Symm 600mm

CN266001

Rotortech Carbon 3D Competition Symmetrical 600mm

CN266022

RotorTech Carbon 3D Sport Symmetrical 600mm

CN260853

Rotortech Carbon Tail Blades Symmetrical 85mm

The Raven 50 contains symmetrical rotor blades for sport and aerobatic flying. For your convienence

you can also use semi-symmetrical for smooth aerobatics and scale flying.

Step 45B Care and installation of Hurricane Carbon Blades - Raven 50

R-50

Step 45C Replacement High Performance Rotorblades Main & Tail