UniVert User Manual

104

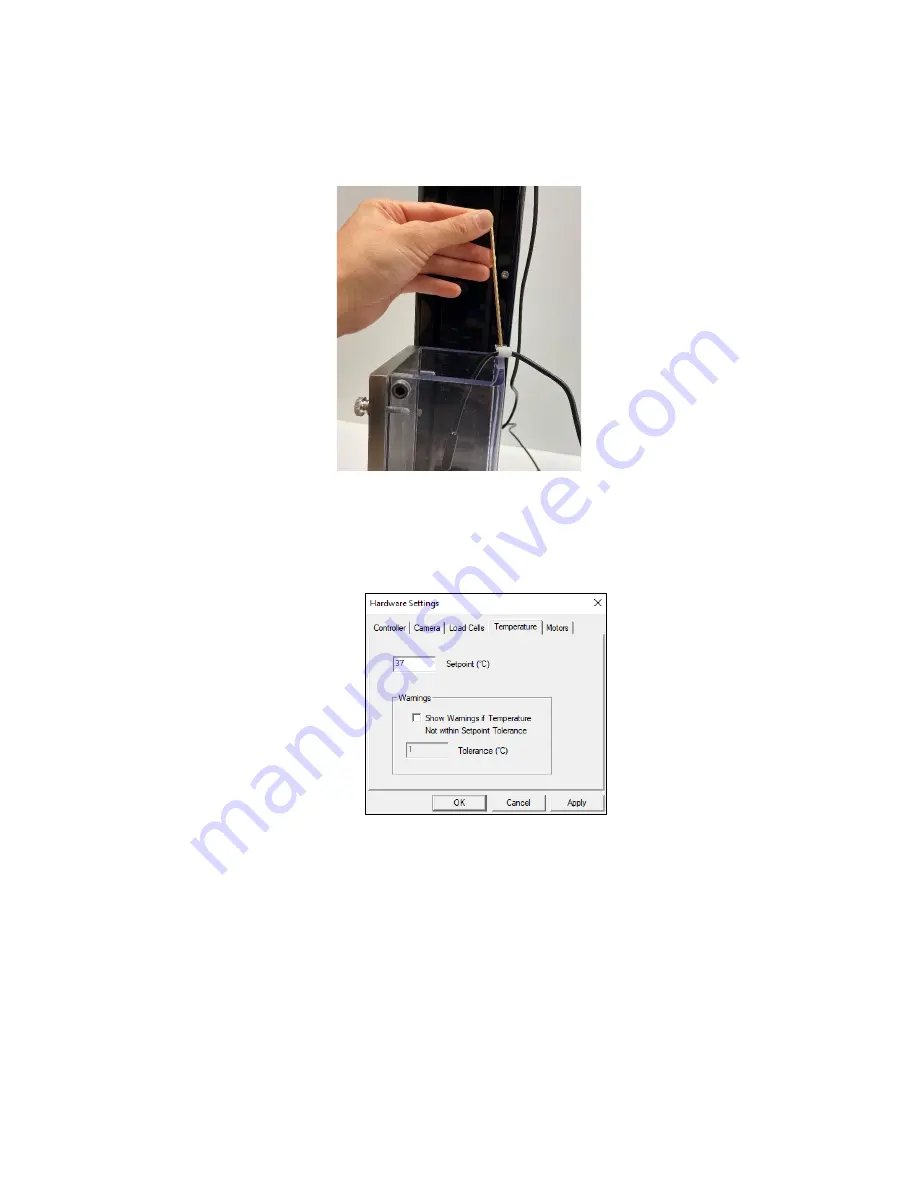

8. Secure the temperature sensor to the top of the chamber using an M4x8 Flat head

fastener and the supplied D-clip

9. To activate the fluid chamber heater, the unit must be powered on and the heater cable

must be connected (the computer and software do not need to be on yet). At this point,

the heater will warm the fluid to the last used temperature set point. The temperature set

point can be changed by selecting Hardware from the Settings menu.

10. Typically, the heater will take 30 to 60 minutes to warm a full fluid chamber from room

temperature to 37°C and will take up to 90 minutes to stabilize at this temperature.

Summary of Contents for UniVert

Page 1: ...UniVert Mechanical Test System User Manual version 3 0 ...

Page 36: ...UniVert User Manual 31 ...

Page 78: ...UniVert User Manual 73 ...

Page 79: ...UniVert User Manual 74 ...

Page 80: ...UniVert User Manual 75 ...

Page 81: ...UniVert User Manual 76 ...

Page 82: ...UniVert User Manual 77 ...