INSTALLATION

Always wear the appropriate protective apparel when working on

or around the pumping equipment. Safety glasses with side shields,

heavy work gloves (use insulated work gloves when handling hot

items), steel-toed shoes, hard hat, and any other protective gear as

needed for protection. One example of other gear would be breath-

ing apparatus when working near toxic materials. Use lifting

devices, manufactured expressly for the purpose of lifting, to move

the pumping machinery. Do not attempt to lift the assembly or its

components manually. Use only devices with lifting capabilities in

excess of the weight of the unit being lifted. Inspect straps, chains,

hooks, etc. for damage and lifting capability before use. Lift only at

the center of gravity.

Personal injury, death, and/or equipment damage could occur if

good lifting practices are not used.

APPLICATION AND REAPPLICATION

At the time of installation, the equipment received should have

already been selected for the service required. You must read the

paperwork for the installation and check the serial number of the

pump to assure that you are installing the correct pump into the ser-

vice for which it was selected.

Many pumps look identical from the outside but can be made of dif-

ferent materials and/or be constructed differently inside. Personal

injury, death, equipment damage, product (pumpage) damage,

and/or product loss could occur if the incorrect pump is installed.

Do not transfer an existing pump to any other service conditions until

you have thoroughly reviewed the pump construction, materials, siz-

ing, sealing, pressure containing capability, head/capacity capabili-

ty, and temperature capability with respect to the required service.

Consult your Dean Pump sales engineer with all the service require-

ments and a full description of the existing pump (including the serial

number), seal, and sub-systems so that we can assist you in a suc-

cessful reapplication.

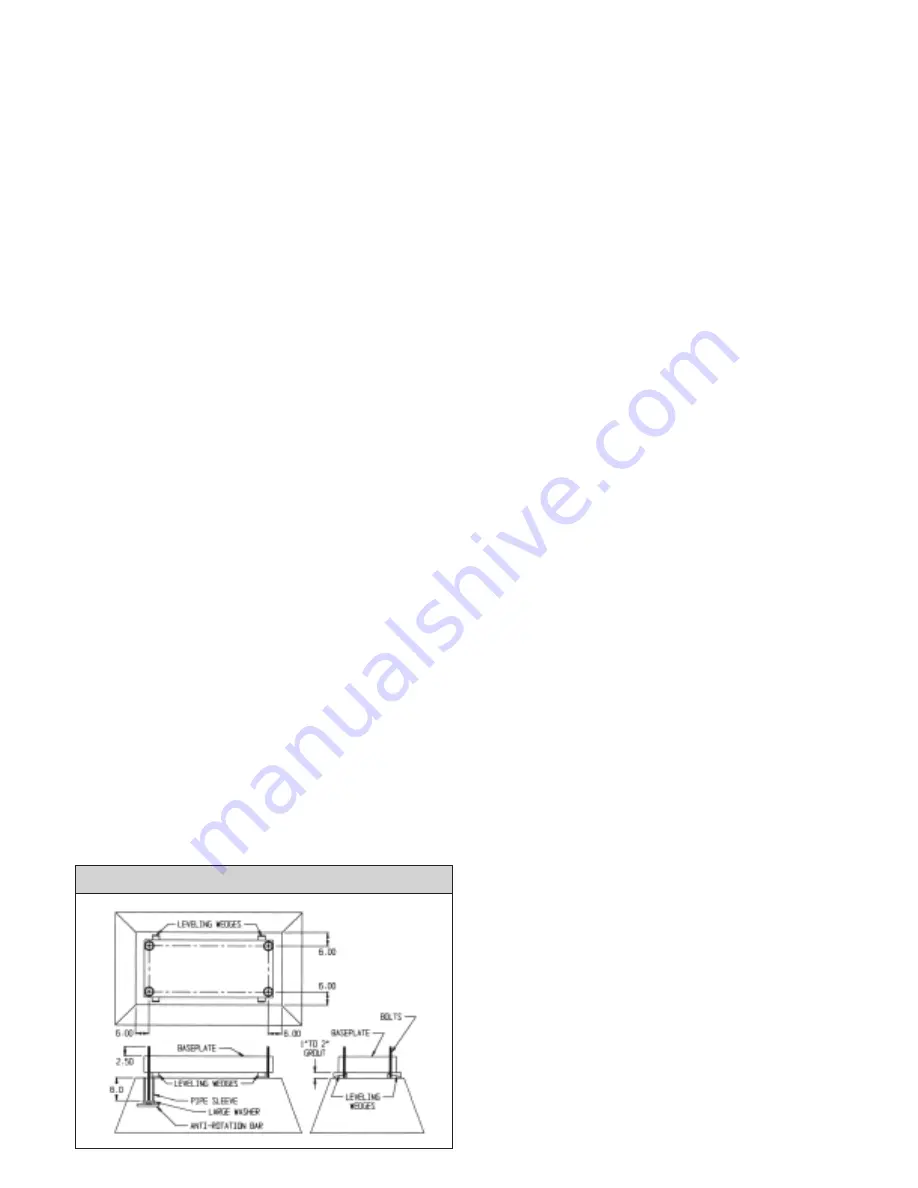

PUMP FOUNDATION

The pump foundation provides rigid support to the baseplate and

maintains the alignment of the pumping unit. Baseplates are

designed to rigidly support the pump and driver without vibration or

distortion only when they are properly set, leveled, and secured to

the foundation.

The purchaser may elect to mount the pump without grouting the

baseplate. In any case the baseplate must be fully supported by the

customer’s mounting means to prevent vibration and distortion.

BASEPLATE MOUNTING AND ALIGNMENT

The sequence of mounting which must be observed for proper base-

plate and pump mounting is:

1) Place baseplate, with pump and driver mounted thereon, on the

pump foundation.

2) Use wedges under the baseplate edges, at each foundation

bolt, to properly support and level the unit. Check this with a

spirit level. Pull down the baseplate mounting bolt nuts tightly

and recheck for level. Correct if necessary.

3) Align the driver to the pump. See

“Pump and Driver

Alignment’’

on page 4.

4) Grout the baseplate.

Do not grout the baseplate to the founda-

tion until the pump and driver are correctly aligned.

The

baseplates are provided with grouting holes. Fill the entire

void under the baseplate with grout and firmly embed the

baseplate edges.

5) Connect the suction and discharge piping without forcing the

piping into position. See

“Suction and Discharge Piping’’

on

page 4. The pipe flanges must line up with the pump flanges

“

freely

”.

Install a

“

new

”

bolt, of the correct size per ASME/ANSI

B16.5 and the correct material per ASME/ANSI B16.5, in

every bolt hole. Tighten all bolts evenly. Use only new

uncorroded fasteners.

WARNING:

Strain caused by “forcing”, improper flange bolting, and/or

misalignment may cause failure of the pumping unit, flanges, piping

and/or fluid (pumpage) release which could cause personal injury,

death, and/or damage to this and/or other equipment.

6) Recheck pump and driver alignment to ensure that no distortion

of the pump unit has been caused by piping strain. Correct

piping if misalignment has occurred and again align pump and

driver.

7) Connect all other (auxiliary) piping necessary for safe and

successful operation of the equipment in the specific service

conditions of the application. See

“Pump Cooling

Requirements”

on page 6.

WARNING:

Make sure that all piping is installed into its correct connection.

Installation of a pipe into an incorrect location could result in an

explosion and personal injury or death as well as damage to this

and/or other equipment. Install pressure relief valves in any cavities

that could be subjected to pressures in excess of the allowable work-

ing pressure. Explosion, personal injury, death, and/or damage to

this and/or other equipment may occur if pressure exceeds allow-

able.

One example of the above would be the cooling jacket around the

seal chamber. If this chamber were full of water and someone

would close both the inlet and outlet valves and then operate the

pump at 500 degrees fahrenheit, the vapor pressure of the water,

665 PSIG, would far exceed the capacity of the jacket and possibly

other parts. In this example, a relief valve must be installed between

the pump and the outlet valve.

8) Recheck the alignment between the driver (motor,

turbine, or engine) and pump shafts. Installation of piping

3

T

YPICAL

F

OUNDATION

L

AYOUT