11

4 Installation

4.1 Software installation

Recommended computer properties are listed in Table 4.1:

Table 4.1. Recommended computer properties.

Operating system Windows 10

Processor

Intel i5 or i7, preferably latest generation multicore processor

RAM memory

8-16 GB (depending on the recording requirements)

Hard disk

SSD with sufficient capacity (depending on the recording requirements)

Display

High quality display with wide viewing angle

GigE

At least two connectors, if two cameras are to be connected to the same computer

Ventilation

Efficient ventilation to prevent heating

If applicable, please uninstall old software version completely before installing new software

version!

Insert the CAVITAR Capture software CD into the CD drive and run the setup file (if the

setup doesn’t start automatically).

In some cases it may be necessary to disable firewall and/or virus software. As an example, in

Windows 10 the “Check apps and files” feature under Windows Security App & Browser

Control may need to be turned off. Please consult your IT support if needed.

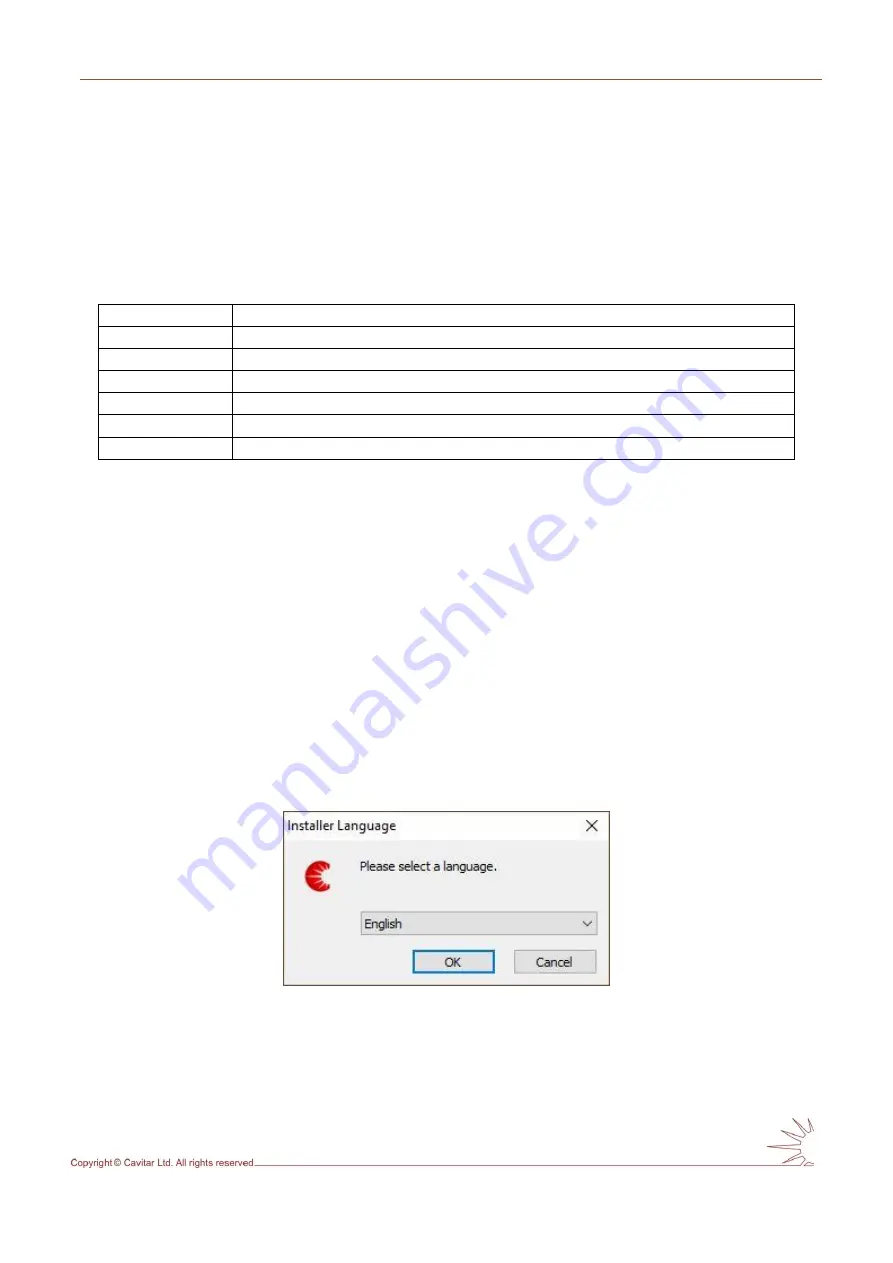

The screenshots below show a typical installation procedure for Windows 10. The actual

appearance of the windows may vary.

Fig. 4.1.

Select language and click “OK”.