Operator's Manual

HPS09 Pellet Stove

Check for parts online at

www.castlestoves.com

or call 800-345-6007 M-F 8-5 CST

15

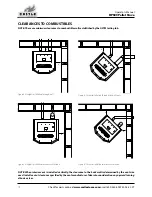

outside air connection

Connection from the intake pipe (2” diameter pipe in rear of

stove) to the outside of the house is REQUIRED for mobile

home installation. It is recommended in tightly sealed

homes with exhaust fans such as kitchen or bathroom

fans. This will eliminate poor performance due to negative

pressure.

Only noncombustible pipe 2” (or greater) in diameter is

approved to use for outside air connections (straight or

flexible).

Pvc pipe is not approved and should never

be connected to the stove.

If the air inlet is connected to the outside, it MUST be

terminated with a vertical 90º bend (down) or with a

wind hood. Failure to do so could result in a burn back

during high winds blowing directly up the air inlet during

a simultaneous power failure.

Blockage, excessive length, or extra bends in the air intake

pipe will starve the stove of combustion air. A 90º bend is

equivalent in restriction to approximately 30” of straight

inlet pipe.

mobile home

Installation in a mobile home should be in accordance

with the manufactured home and safety standard.

Department of Housing and Urban Development (HUD)

CITE: 24CFR3280.707 stating this stove must be vented

to the outside. In addition to the standard installation

instructions, the following requirements are mandatory

for installation in a mobile home:

1. The stove must be permanently attached to the

floor.

2. Stove must have an outside air source.

3. Stove must be electrically grounded to the steel chassis

of the mobile home.

4. All vertical chimney vents must have wall supports.

5. All exhaust systems must have a spark arrestor.

6. Check with local building offficials to see if other codes

may apply.

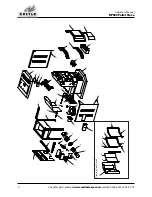

understanding your stove

Your Castle pellet stove utilizes a vertical auger fuel feed

system that is operated by a microprocessor controlled

digital circuit board. The digital circuit board allows the

vertical auger fuel system to run in a timer based, non-

continuous cycle; this cycling allows the auger to run

for a predetermined amount of time. The auger pushes

pellets up a chute located in the hopper. The pellets will

then turn and fall through another chute into the burn

pot. Your stove is equipped with an automatic ignition

system that should ignite the fuel within 3-5 minutes of

pressing the On/Off button . As pellets fill the burnpot

and ignite, outside air is drawn across the fuel and heated

during the combustion process which is then pulled across

the heat exchanger by the exhaust motor or the draft fan.

As the stove reaches operating temperature, room air is

then circulated around the heat exchanger by a room air

blower, distributing warm air into the room.

The amount of heat that is produced by the stove is

proportional to the rate of fuel that is burned. This rate is

controlled by pressing the fuel control button <->.

Because a forced draft pressure is required for the

combustion process inside your stove, it is extremely

important that the exhaust system be properly installed

and maintained. Also, the doors must remain closed while

in operations and the seals on the doors must be properly

maintained.

Warning

do not connect to any air distribution

duct or system.

do not install in a sleePing room.

Caution

the operatIon of exhauSt fanS Such aS

bathroom fans, attic fans, etc. might

starve the Pellet stove of combustible

air creating a negative Pressure in the

room. Provide adequate ventilation

in the room accomPanying the Pellet

stove. if not, the Pressure switch may

shut off oPeration of the Pellet stove.

the struc tur al integrity of the

manufactured home floor, wall, and

ceiling/roof must be maintained.

I