IOM-DA8

2

table below) before shutting off the process fluid

supply pressure. If the regulator is specified with

a fully supported diaphragm, then the diaphragm

will withstand a loading pressure equal to the

Diaphragm Proof Rating for the fully supported

diaphragm.

9. Upstream Sensing Installation Considerations –

Internal or External Sensing:

a. The regulator may be installed with internal or

external sensing. Unless otherwise specified,

the regulator is supplied by factory with internal

sensing. The regulator may be con vert ed in

the field to external sensing (see Section VII

Maintenance, Paragraph H).

b. Reference DA8-TB, Table DAG-12 for recom-

mendations for applying external pressure

sensing.

c. For internal sensing, no external line is used.

For external sensing, use an external control

line. The line is connected from the port (1/4"

NPT) on the side of the body di a phragm flange

to an upstream pressure tap. The pressure

tap should be located a minimum of 10 pipe

diameters upstream of the regulator. It is

recommended that the upstream pressure

tap be located close to the point of use to

minimize the adverse affect of variable line

losses. A tubing outer diameter of 0.25 inch

is adequate for short sensing lines (less than

4 feet). Use 3/8" tubing or 1/4" Sch 40 pipe

for sensing lines of 5 to 50 feet.

d. For condensable vapors (i.e. steam) slope

the external sensing line downward 2 to 5

de grees to upstream piping to prevent water

pock ets, which allows the diaphragm chamber

to always be self draining. The external sens-

ing line may be sloped upward for liquids or

gases. (i.e., non condensable fluids)

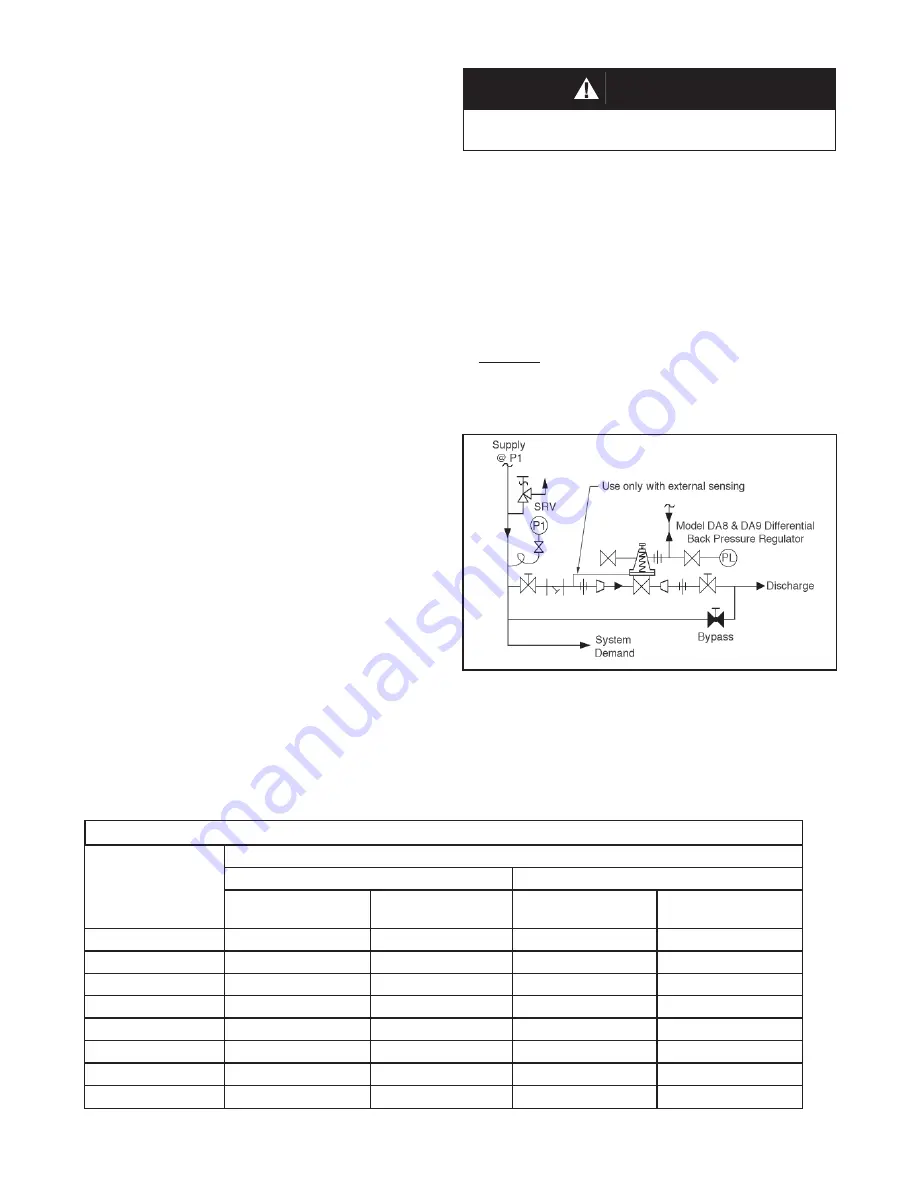

Recommended Piping Schematic for

Differential Back Pressure Station

CAUTION

The proof test pressure must not exceed the

diaphragm and body rating for the regulator.

A hydrostatic or pneumatic proof test is allowable un-

der the following conditions for the standard diaphragm

construction: Uniformly pressurize the valve body inlet,

valve body outlet, and loading chamber to the lesser of

the Diaphragm Proof Rating or 1.5 times the Inlet Pres-

sure Rating shown on the nameplate. For example, a

1" DA8 with Cast Iron Body and Spring Chamber, Neo-

prene Diaphragm (BC) has an Inlet Pressure Rating of

400 psig CWP. The lesser pressure of 1.5X 400 psig =

600 psig and the BC diaphragm proof rating of 750 psig

is

600 psig

. Therefore, uniformly pressurizing the DA8

to 600 psig is allowable. Take care to uniformly depres-

surize at end of test.

TABLE 1 – DIAPHRAGM PROOF RATING IN PSIG (BARG)

Diaphragm Material

Body Sizes – inch (mm)

1/2" - 2" (DN15 - 50)

2-1/2" - 4" (DN65 - 100)

Standard Diaphragm

Construction

OPT-81 Full

Diaphragm Support

Standard Diaphragm

Construction

OPT-81 Full

Diaphragm Support

BC, EPR

750 (51.7)

1200 (82.7)

450 (31.0)

800 (55.2)

HK, NBR, HK+TFE

300 (20.7)

1200 (82.7)

225 (15.5)

600 (41.4)

FK

500 (34.5)

1200 (82.7)

225 (15.5)

600 (41.4)

Elastomeric TFE

125 (8.6)

125 (8.6)

125 (8.6)

125 (8.6)

17-7 PH SST

500 (34.5)

1500 (103)

N/A

N/A

Be-Cu

300 (20.7)

750 (51.7)

N/A

N/A

302 SST

350 (24.1)

800 (55.2)

N/A

N/A

Inconel 718

500 (34.5)

1500 (103)

N/A

N/A