21

20

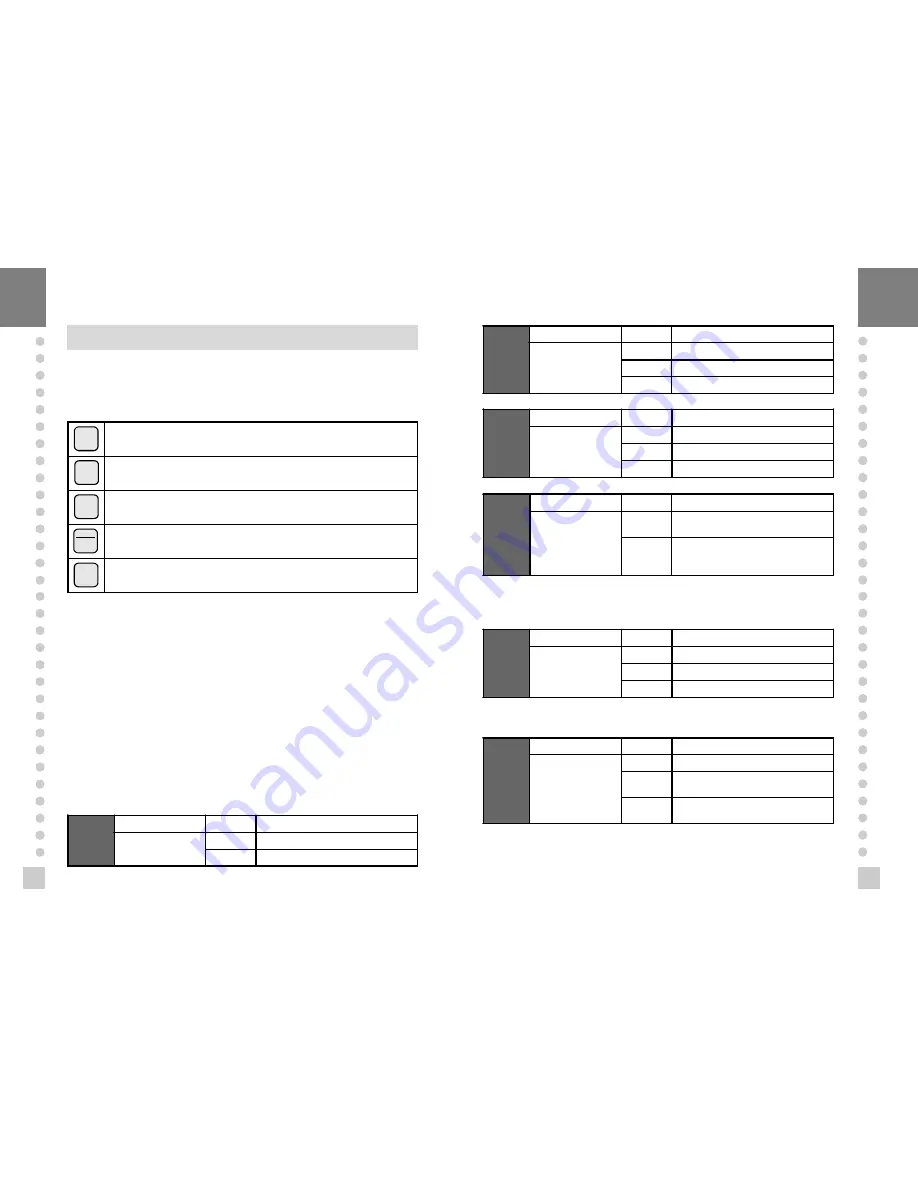

SET MODE

1. How to enter

Turn on the power while pressing the

TARE

key on the front of the indicator.

2. Available keys

used to save inputted value and exit to menu selection.

used to set the current value to zero

used to set the current value x10.

used to set the current value +1.

used to set the current value -1.

3. Set Value Conversion Menu

F01 Change of display unit

F02

SET

Key usage

F03 Serial port Usage

F04 Auto Print Usage

F05 Speed control of weigh display

F06 Automatic zero condition set

F07 Weight backup function set

F08 External Input 2 Usage

F09

ZERO

key operation range set

F10 Device number

F11 Baud rate set

F12 Data set sent to Computer

F13 Hold type set

F14 Set Clock

F20 Relay mode (CI-1560A)

F01

Function

Display

Description

SET display

unit(0~1)

F01 0

Unit : kg

F01 1

Unit : ton

F02

Function

Display

Description

SET key usage(0~2)

F02 0

is Hold key

F02 1 is Total data print

F02 2

is Start key in relay mode

F03

Function

Display

Description

Serial Port usage

(0~2)

F03 0

Not Used

F03 1 Connection to Serial Printer

F03 2

Connection to P.C or RemoteDisplay

F04

Function

Display

Description

Automatic print(0~1)

F04 0

Manual print-whenever you press

the key, it will be printed.

F04 1

Automatic print-when the weight is

stable or you press the key, it will be

printed.

F05

Function

Display

Description

Speed control of

weighing display

(Digial filter function,

1~9)

F05 1 In high speed

F05 5

In normal speed

F05 9

Very slowly

4

Note 1. Upon setting the automatic print, the print is carried out without

pressing the print key when the weight is in stable state.

Note 2. It shall be in 1 of F03.

4

Note . Adjust the speed variation of the weight on the screen to be suitable

for the current usage.

F06

Function

Display

Description

Automatic zero

condition set(0~9)

F06 0

No compensation

F06 2

Compensation for gradual change

below two division for 3 seconds.

F06 9

Compensation for gradual change

below nine division for 3 sec.

TARE

3

NET

GROSS

5

3

SET

ZERO