UNPACKING AND INSTALLATION (continued)

6

INSTALLATION

Counter-Top Models

Tools Needed:

NSF approved food grade silicone, level

1. Place the cabinet in an area where the ambient air temperature is constant and

at least 70°F (21°C). Make sure the countertop is fixed, level and strong

enough to support the weight of the cabinet and it is at the proper counter

height for convenient use.

2. Verify that the unit is level. The unit must be within 0.5° of level. Use shims to

level the unit, if necessary.

3. Apply NSF-approved sealant around the edge of the unit and the countertop to

seal it in place.

Floor Models

Tools Needed:

power drill, concrete screws, anchors, level

3) Using an appropriate device, such as

forklift or pallet jack, lift the unit off of the

pallet, remove the pallet, and then lower

the cabinet to the ground.

4) Move the cabinet to the desired location.

5) Lock the front two casters to hold the

cabinet in place.

Appliance should be thoroughly cleaned be-

fore use. See CLEANING INSTRUCTIONS,

page 16.

INSTALLATION CLEAR-

ANCES:

Allow at least 2”

ventilation gap at the top,

sides and rear of the cabi-

net. Allow at least 36” clearance at

the front of the cabinet. Pass through

cabinets require 36” at the front and

rear of the cabinet.

Before using, familiarize

yourself with the

appliance controls. Read

entire manual before operating

this cabinet.

1

2

3

4

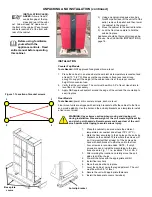

Figure 1.1 Location of bracket screws

Floor mount units are shipped with anti-slip brackets to affix the cabinet to the floor

and provide stability. Use the holes on the anti-slip brackets as a template to install

a floor mount model.

WARNING: Use extreme caution when moving and tipping unit

during installation. Size and weight of the unit create significant tip

and pinch point hazards. Remain aware and keep clear of the unit/

pinch points while tipping to avoid serious injury.

1. Place the cabinet in an area where the ambient

temperature is constant and at least 70°F (21°C).

2. Mark the floor according to the 4 holes on the anti-slip

brackets on the cabinet. This is where the screws will

go. It is important that at least 2 of the 4 screws be

used with each bracket to affix the unit to the floor.

Four screws are recommended. NOTE: If only 2

screws are used, install them according to the loca-

tions shown in Fig. 1.1, i.e. locations 1 & 4 or 2 & 3

3. After marking the locations, carefully move the unit

aside to drill floor holes

4. Pre-drill the holes with the appropriate drill bit

5. Install floor anchors

6. Move the cabinet back in place

7. Level the cabinet, using the leg adjustment. The unit

must be within 0.5° of level.

8. Secure the unit with appropriate fasteners

9. Install the base plate covers (included)

Anti-slip bracket

Base plate

covers