45

SPACE SENSOR CONTROL — If the unit is in cooling,

operating under space temperature control, the economizer is

available for cooling, and no compressors are operating, the

economizer will control the SAT to either

Setpoints

→

LCSP

or

Setpoints

→

HCSP

(see Table 40). If a compressor is ON, the

economizer will try to position itself at the economizer maxi-

mum cooling position (

Configuration

→

ECON

→

EC.MX

).

If the control senses low suction pressure for any active re-

frigerant circuit when the economizer is also providing cooling,

the maximum allowable economizer position will be reduced.

Factory default configurations have been qualified over a large

range of conditions and should only be changed with care. For

unit troubleshooting, factory default maximum economizer

limits for this condition are provided in Table 41.

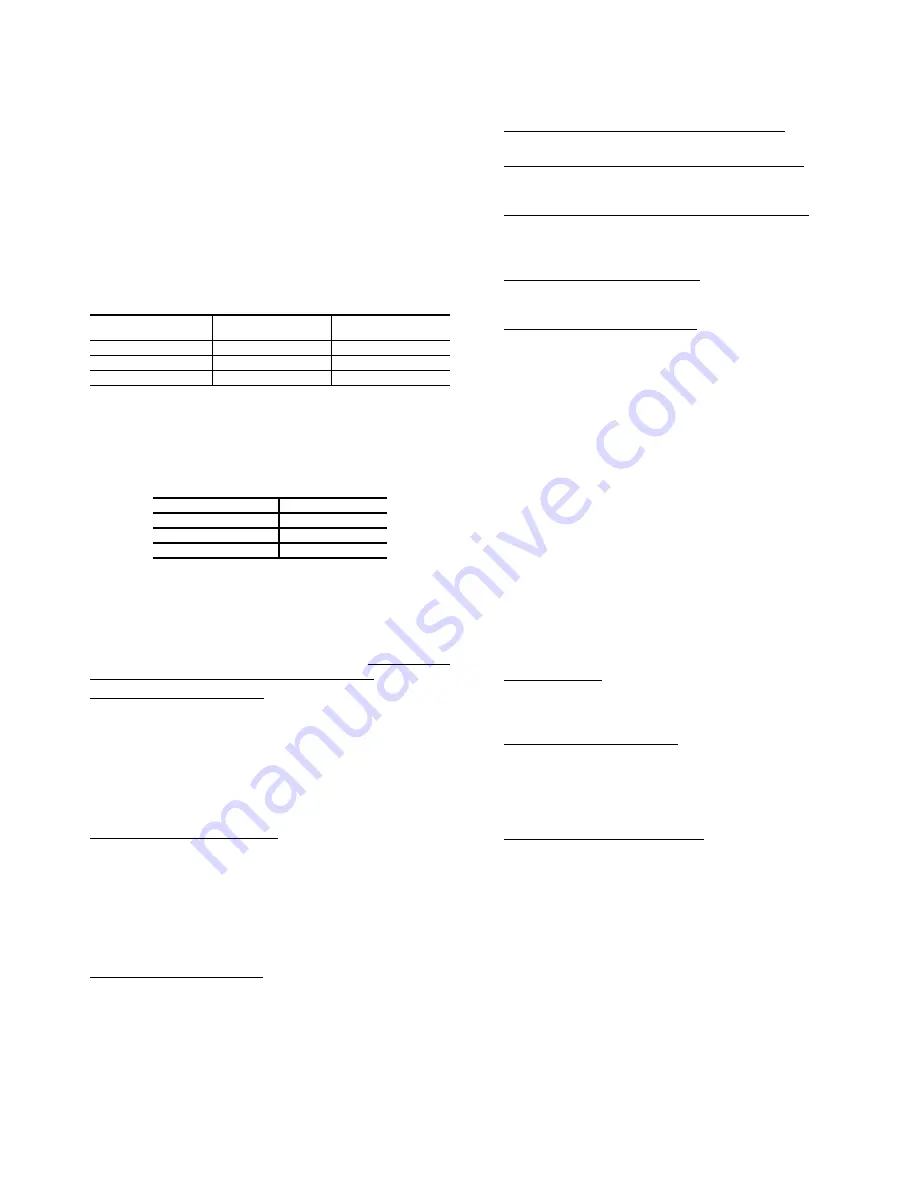

Table 40 — LCSP and HCSP Transitions for

Space Temperature Mode

LEGEND

Table 41 — Maximum Economizer Limits During

Low Suction Pressure

ECONOMIZER ACTUATOR COMMUNICATIONS — The

configuration Economizer Control Type determines the

communication method, either digital or analog, used to

communicate between the ECB and the economizer actuator.

Economizer Control Type is accessible via the Scrolling

Marquee at

Configurations

→

ECON

→

E.CTL

. The power to

the unit must be cycled after

E.CTL

is changed.

E.CTL =

1

(Digital/Position) — When

E.CTL

is set to 1, the

ECB will communicate with the economizer actuator using the

digital protocol. The ECB 4 to 20 mA output will represent the

actuator’s actual position. Because the wiring has a built-in

500-ohm resistor, the 4 to 20 mA signal is converted to a 2 to

10-v signal that is accessible via field connection terminal board

TB2-8 and TB2-9. However, before this signal can be read, the

violet wire that connects the actuator to field connection termi-

nal board TB2-J10-8 must be removed or cut.

E.CTL =

2

(Digital/Command) — When

E.CTL

is set to 2,

the ECB will communicate with the economizer actuator using

the digital protocol. The ECB 4 to 20 mA output will represent

the actuator’s commanded position. Because the wiring has a

built-in 500-ohm resistor, the 4 to 20 mA signal is converted to

a 2 to 10-v signal that is accessible via field connection termi-

nal board TB2-8 and TB2-9. However, before this signal can

be read, the violet wire that connects the actuator to field con-

nection terminal board TB2-J10-8 must be removed or cut.

E.CTL =

3

(Analog Control) — When

E.CTL

is set to 3, the

ECB will communicate with the economizer actuator using the

4 to 20 mA analog signal wired to TB2-8 and TB2-9 along

with the 500-ohm resistor producing a 2 to 10-v signal for the

actuator. While in this mode, the actuator’s built-in 2 to 10-v

feedback signal is accessible via TB2-9 and TB2-10.

UNOCCUPIED FREE COOLING — The unoccupied free

cooling algorithm attempts to maintain the building space at

the occupied cooling set point during unoccupied periods if the

conditions in the building and the outdoors are suitable. Three

different configurations define this algorithm: Unoccupied

Free Cooling (

Configuration

→

ECON

→

UEFC

), Free Cool-

ing Preoccupancy Time (

Configuration

→

ECON

→

FC.TM

)

and Free Cool Low Temp Limit (

Configuration

→

ECON

→

FC.LO

).

Configuration

→

ECON

→

UEFC

= 0

(Disabled) — When

UEFC

= 0

, unoccupied free cooling is disabled.

Configuration

→

ECON

→

UEFC

= 1

(Unoccupied) — When

UEFC

= 1

, unoccupied free cooling can occur whenever the

building is unoccupied.

Configuration

→

ECON

→

UEFC

= 2

(Preoccupancy) — When

UEFC

= 2

, unoccupied free cooling can only occur when the

time to the next occupied period is less than

Configuration

→

ECON

→

FC.TM

minutes.

Configuration

→

ECON

→

FC.TM

—

FC.TM

is the configura-

tion that determines how many minutes before occupancy that

free cooling can occur.

Configuration

→

ECON

→

FC.LO

— Unoccupied free cooling

cannot occur if the Outdoor Air Temperature (

Tempera-

ture

→

AIR.T

→

OAT

) is less than

FC.LO

.

POWER EXHAUST — To enable power exhaust,

Configu-

ration

→

ECON

→

PE.EN

must be set to

ENBL

. If power ex-

haust is enabled, Power Exhaust 1 will turn on when the econo-

mizer position is greater than the value of

Configuration

→

ECON

→

PE.1

. If power exhaust is enabled, Power Exhaust 2

will turn on when the economizer position is greater than the

value of

Configuration

→

ECON

→

PE.2

. There are small time

delays to ensure that rapid cycling does not occur.

Optional Humidi-MiZer™ Dehumidification Sys-

tem —

Units with the factory-equipped Humidi-MiZer

option are capable of providing multiple modes of improved

dehumidification as a variation of the normal cooling cycle.

The Humidi-MiZer option includes additional valves in the

liquid line and discharge line of each refrigerant circuit, a small

reheat condenser coil downstream of the evaporator, and

Motormaster® variable-speed control of some or all outdoor

fans. Operation of the revised refrigerant circuit for each mode

is described below.

NOTE: x = refrigerant circuit A or B.

Normal Cooling — Refrigerant flows from the outdoor

condenser through the de-energized 3-way valve (RH1.x) to

the expansion device. Reheat2 Valve (RH2.x) is closed. See

Fig. 6.

Reheat 1 (Subcooling Mode) — This mode increases latent

cooling and decreases sensible cooling compared to normal

cooling. Refrigerant flows from the outdoor condenser,

through the energized 3-way Valve (RH1.x), and through the

reheat condenser coil to the expansion device. Reheat2 Valve

(RH2.x) is closed. See Fig. 7.

Reheat 2 (Hot Gas Reheat Mode) — This mode provides

maximum latent cooling with little to no sensible capacity.

This mode can operate to provide dehumidification when there

is no cooling demand. Like Reheat 1 mode, refrigerant flows

from the outdoor condenser, through the energized 3-way valve

(RH1.x), and through the reheat condenser coil to the expan-

sion device. Reheat2 Valve (RH2.x) is open which provides

some compressor discharge gas to the reheat condenser to fur-

ther increase the reheat of the evaporator air stream. See Fig. 8.

Units with multiple circuits can operate with additional

staging of the cooling and dehumidification capacity. When

there is only cooling demand, based on a space temperature

sensor or thermostat, one or more circuits will operate in

normal cooling mode. When there is only dehumidification

demand, based on a space humidity sensor or switch, all

circuits will operate in reheat2 mode. When there is both

cooling demand and dehumidification demand, all circuits will

operate in either reheat1 or reheat2 mode, with the portion of

reheat1 circuits determined from the cooling demand.

CURRENT SAT

SET POINT

COOL DEMAND

(

∆

F)

NEXT SAT

SET POINT

LCSP

>0.5

HCSP

HCSP

<0

LCSP

LCSP

<–0.5

Exit Cooling

HCSP

—

High Cool Set Point

LCSP

—

Low Cool Set Point

SAT

—

Supply-Air Temperature

COOLING STAGE

LIMIT (%)

Bottom

50

Middle

50

Top

0

Summary of Contents for 48PG24

Page 68: ...68 Fig 14 Low Voltage Control Schematic 48PG20 28 Units without Humidi MiZer System a48 7627...

Page 69: ...69 Fig 15 Low Voltage Control Schematic 48PG20 28 Units with Humidi MiZer System a48 8227...

Page 70: ...70 Fig 16 Low Voltage Control Schematic 50PG20 28 Units without Humidi MiZer System a48 7778...

Page 71: ...71 Fig 17 Low Voltage Control Schematic 50PG20 28 Units with Humidi MiZer System a50 8101...

Page 72: ...72 Fig 18 Power Schematic Units without Humidi MiZer System a48 7628...

Page 73: ...73 Fig 19 Power Schematic Units with Humidi MiZer System a48 8228...

Page 74: ...74 Fig 20 Component Arrangement Units without Humidi MiZer System a48 8229...

Page 75: ...75 Fig 21 Component Arrangement Units with Humidi MiZer System a48 8230...

Page 105: ......