14

Condenser coil

We recommend, that finned coils are inspected regularly to

check the degree of fouling. This depends on the environment

where the unit is installed, and will be worse in urban and

industrial installations and near trees that shed their leaves.

For coil cleaning proceed as follows:

•

Remove fibres and dust collected on the condenser face

with a soft brush (or vacuum cleaner).

•

Clean the coil with the appropriate cleaning agents.

We recommend TOTALINE products for coil cleaning:

Part No. P902 DT 05EE: traditional cleaning method

Part No. P902 CL 05EE: cleaning and degreasing.

These products have a neutral pH value, do not contain

phosphates, are not harmful to the human body, and can be

disposed of through the public drainage system.

Depending on the degree of fouling both products can be used

diluted or undiluted.

For normal maintenance routines we recommend using 1 kg

of the concentrated product, diluted to 10%, to treat a coil

surface of 2 m

2

. This process can either be carried out with

a TOTALINE applicator gun (part No. TE01 WA 4000EE)

or using a high-pressure spray gun in the low-pressure position.

With pressurised cleaning methods care should be taken not to

damage the coil fins. The spraying of the coil must be done:

- in the direction of the fins

- in the opposite direction of the air flow direction

- with a large diffuser (25-30°)

- at a distance of 300 mm.

The two cleaning products can be used for any of the following

coil finishes: Cu/Cu, Cu/Al, Cu/Al with Polual, Blygold and/or

Heresite protection.

It is not necessary to rinse the coil, as the products used are pH

neutral. To ensure that the coil is perfectly clean, we

recommend rinsing with a low water flow rate. The pH value

of the water used should be between 7 and 8.

WARNING: Never use pressurized water without a large

diffusor. Concentrated and/or rotating water jets are strictly

forbidden.

Correct and frequent cleaning (approximately every three

months) will prevent 2/3 of the corrosion problems.

Fan motor replacement

This presents no special problems. The work is done from

above the unit.

•

Remove the grille with its support air duct assembly.

•

Remove the fan shaft protection cap.

•

Pull the fan from the shaft using a FACOM U35, or

similar, hub puller.

•

Unscrew the fan motor fixing bolts.

Remove only the lower bolts to prevent the motor from

falling.

•

Withdraw the fan motor.

Installation is in the reverse order. Take care not to damage the

plastic components when installing the fan and position the fan

to maintain a clearance of 117 + 0/-2 mm between the upper

edge of the fan and the upper edge of the volute.

CAUTION: On unit sizes 30GH/GZ 040-245 the fan rotation is

counter clockwise, viewed from above.

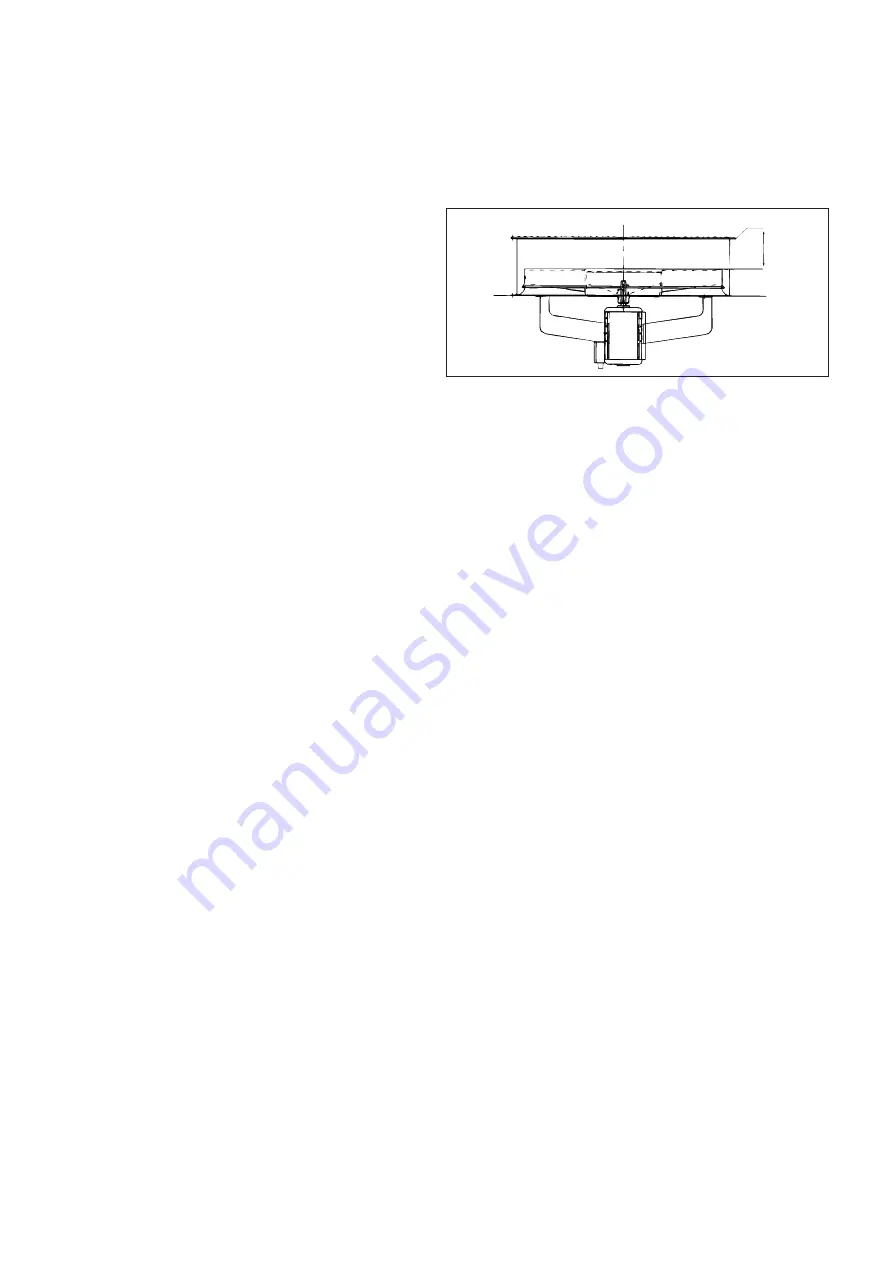

30GH/GZ 040-245 fan

Fan motor protection

All units are equipped with a fan protection circuit breaker.

Refrigerant circuit

Thermal expansion valve (TXV)

The function of the thermal expansion valve is to control the

flow of liquid refrigerant. The valve is controlled by a sensor

bulb in the compressor suction line. It is factory set to maintain

refrigerant superheat of 4 K.

This setting should not be changed unless absolutely necessary.

Filter-drier

The filter-drier keeps the circuit clean and free of moisture. The

sight glass indicates when it is necessary to change the cartridge

in the filter-drier. A temperature difference between the inlet

and the outlet of the filter-drier indicates fouling of the drier.

NOTE: The unit must run for at least 12 hours before it can

give an accurate indication, because only with the unit running

is the indicator in continuous contact with the refrigerant.

Liquid line service valve

This valve provides, in each circuit, a liquid refrigerant charging

port and, in conjunction with the compressor discharge line

valves, enables liquid refrigerant to be pumped to the high

pressure side of the system.

117 +0/-2

Maximum

clearance