62-11785

8–20

8.7.7

Compressor Suction Modulation Valve (CSMV)

The purpose of the CSMV (see

maintain the compressor within its operating envelope,

maximize unit capacity and maintain temperature

control.

If it is suspected that the CSMV is malfunctioning, the

most efficient method of diagnosing the valve is to run

a Pretrip (refer to

). The Pretrip steps will

check the remainder of the system and the CSMV

specific test will check the valve. During the CSMV

specific test the valve will be brought to a preset

position, the unit started and then the valve will be

opened while the control system monitors suction

pressure.

If there is a problem with the valve internal motor/piston

assembly or control system wiring to the valve the test

will fail.

Figure 8.10 Suction Modulation Valve (CSMV)

a. Diagnostics - Control System or Wiring

NOTE

The APX Micro Service Harness, Carrier P/N 07-00515-00 can be used for this procedure.

1. Disconnect the CSMV connector.

2. Place the START/RUN-OFF switch in the START/RUN position, DO NOT ALLOW THE UNIT TO START. When

the MessageCenter displays “SMV CLOSING”, measure the AC voltage on the harness side of the connector

between pins A & B and then between C & D. A voltage (10 to 16 VAC) should be read by the digital voltmeter for

each pair of wires. If the reading is present on all of the wire pairs there is a good signal coming from the control

system.

3. If the reading is not present on one or more of the wire pairs, check the wiring between the control system and

the CSMV connector, or check the control system for proper model number Configuration.

b. Diagnostics - Stepper Motor (SMV)

The valve stepper motor may be tested using a stepper motor drive tester or ohmmeter.

1. To test with a stepper motor drive tester (Carrier Transicold P/N 07-00375-00SV), connect the 4 pin test cable

supplied with the tester to the valve connector, refer to

, and the cable wires to the tester in

accordance with wire and terminal color.

2. Set the step rate to 150 steps per second and either open or close the valve. Each red LED should light

sequentially until all four are illuminated. Any LED failing to illuminate indicates an open on that leg, and a need

to replace the piston and drive motor assembly.

3. To test with an ohmmeter, check the winding

resistance between connector pin A & B and then

between C & D, see

. In normal

ambient, the resistance between the pins should

be 65 to 84 ohms. Also check each terminal to the

coil casing (ground). If an out of tolerance or zero

reading is observed, the piston and drive motor

assembly is to be replaced.

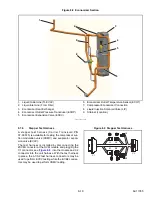

Figure 8.11 CSMV Coil

4 Pin Connector

Drive & Motor

Assembly

Screws

Body

1

2

A (BLACK)

(WHITE) B

(RED) C

D (GREEN)

Summary of Contents for VECTOR 8100

Page 2: ......

Page 4: ......

Page 12: ...62 11785 viii ...

Page 16: ...62 11640 12 ...

Page 18: ...62 11785 ...

Page 24: ...62 11785 1 6 1 3 SAFETY DECALS ...

Page 25: ...1 7 62 11785 ...

Page 26: ...62 11785 1 8 ...

Page 27: ...1 9 62 11785 ...

Page 28: ...62 11785 1 10 ...

Page 30: ...62 11785 ...

Page 50: ...62 11785 ...

Page 82: ...62 11785 ...

Page 96: ...62 11785 4 14 ...

Page 98: ...62 11785 ...

Page 129: ...5 31 62 11785 ...

Page 130: ...62 11785 5 32 ...

Page 134: ...62 11785 6 4 ...

Page 138: ...62 11785 ...

Page 230: ...62 11785 ...

Page 271: ...8 41 62 11785 ...

Page 272: ...62 11785 8 42 ...

Page 274: ...62 11785 ...

Page 286: ......

Page 287: ......

Page 288: ...62 11785 10 8 ...

Page 292: ......

Page 293: ......