Model 99FRD, 100CRD, & 102CRD oil burners — Instruction manual

Carlin part number MN99102 Rev. 08/20/08

– 9 –

3. Prepare burner

Removing/installing head assembly

Use care when handling burner components after the burner

has been firing. Components can be hot and could cause

severe personal injury.

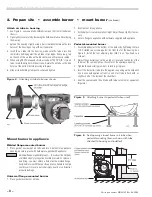

You will need to remove the combustion head assembly for inspection of

the assembly, replacement of the oil nozzle or adjustment of electrodes.

To remove the assembly:

1. Loosen, and then rotate the two screw clamps securing the ignitor in

place. Swing the ignitor plate open.

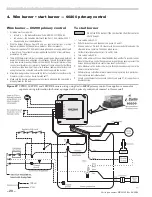

2. See Figure 7. Remove the blower shield by loosening the retaining

screw on its front edge if needed for easier removal or insertion of the

combustion head assembly.

3. Unscrew the oil line fitting and thumb nut at the burner housing.

4. Pull the threaded end of the oil tube into the blower housing.

5. See Figure 7. Rotate the combustion head assembly 180° so the

electrodes are upside down. This places the electrode insulators out

of the way for easy removal.

6. Remove the combustion head assembly by pulling the assembly up

and out of the housing.

7. Handle the assembly with care to avoid bending/moving the electrodes,

or damaging the electrode ceramic insulators.

8. Inspect the gasket on the bottom of the ignitor plate. The gasket prevents

air from escaping from the housing. Replace the gasket if not in good

condition.

9. Inspect the ignitor contact clips. Clean or replace if necessary to ensure

reliable contact with the electrodes.

Install nozzle/check electrodes

1. Loosen the clamp screw on the retention ring assembly (see Figure 10,

page 10). Slide the retention ring assembly off of the nozzle adapter.

Then loosen electrodes to rotate out of the way.

2. Install and tighten the nozzle shown in Table 1, page 3, for retrofit

applications. Install the nozzle given in the appliance manual when

application information for the 99FRD, 100CRD, and 102CRD oil burner

is given.

3. Hold the nozzle adapter securely when removing or replacing the nozzle

(Figure 9). Take care not to damage the electrode insulators or to bend

the electrodes in the process.

To replace the combustion head assembly, reverse the sequence.

• Remember to put the assembly in upside down, so the electrode

insulators are out of the way. Remove, then replace, the blower shield

if necessary for easier removal/insertion of the assembly.

• See Figure 8. For 99FRD or 100CRD burners, you will have to lift the

end of the assembly to guide it through the throttle at the end of the

air tube. DO NOT FORCE.

Use care when tightening the oil line fitting to oil tube extension.

Tighten securely, but do not cross-thread or over-tighten.

Figure 8

Inserting combustion head assembly

Figure 7

Removing/inserting combustion head assembly

Figure 9

Carefully support the nozzle adapter when

installing or removing nozzle