docs.carbide3d.com

8/31/2020

Version 4.0

61

2.

Position your spindle directly above the BitSetter.

a.

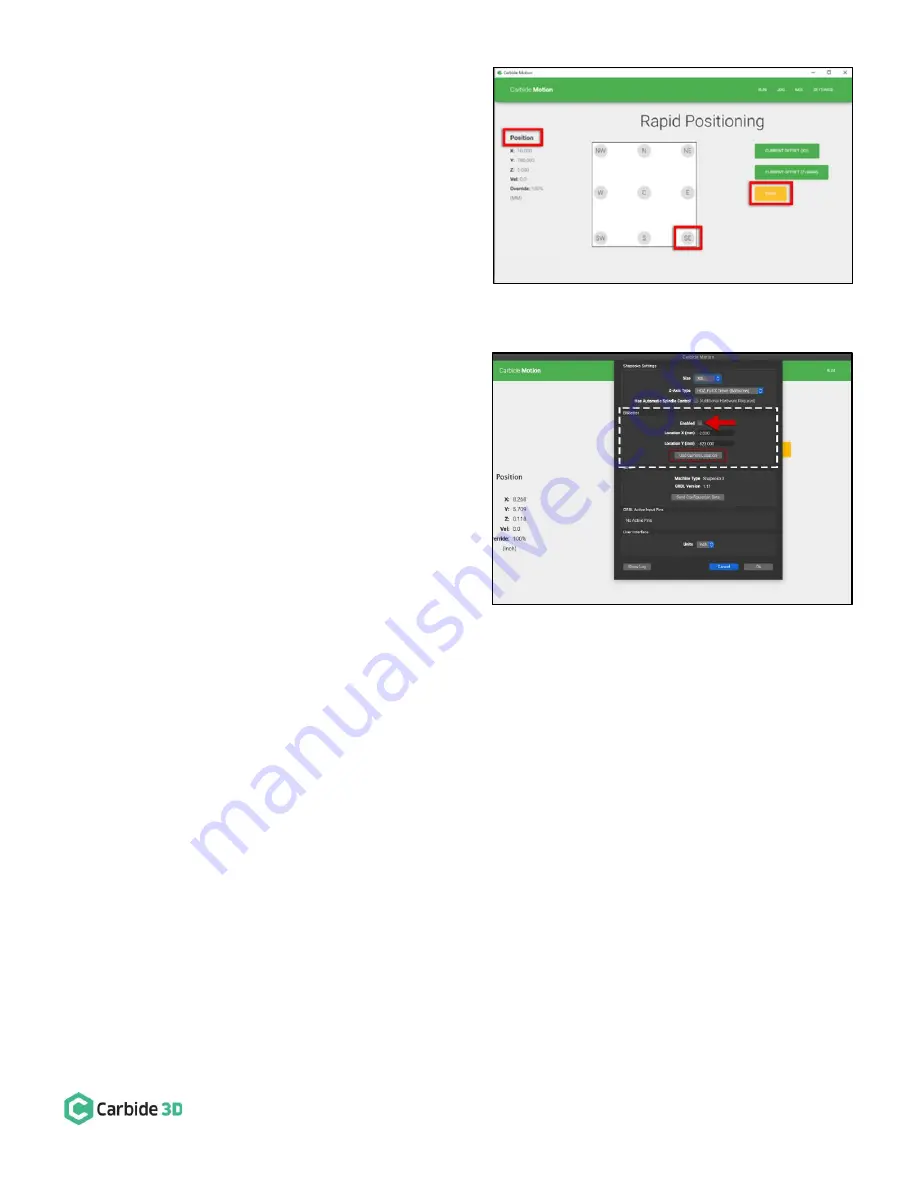

Click the Position label. This will toggle the

view to the machine coordinates. See

Fig. 25

.

b.

Click Rapid Position, then click the SE button

to move the spindle to the front-right of the

machine. Once in position, click

DONE

. See

Fig. 25

.

c.

From the Jog screen, use the arrows on the

screen (or the arrows on your keyboard) to

jog the gantry so the spindle is directly above

the BitSetter.

Once you have the spindle positioned directly above the

BitSetter, we need to permanently save this location:

1.

Click Settings in the top menu bar.

2.

Recalibrate your BitSetter. See

Fig. 26

.

a.

In the BitSetter box, select the Enabled

checkbox.

b.

With your spindle directly above the

BitSetter, click the Use Current Location

button to set the location. This will

permanently save the X/Y location of your

BitSetter.

3.

Click Ok to save and close the window.

Maintenance

4.

The HDZ is pretty much maintenance-free. We recommend keeping it as dust-free as possible. A quick coat of

synthetic oil (such as Mobil Vactra No. 2 Oil) on the rails and ball screw every 6 months. All the parts are

rubber-sealed. You can also inject oil by removing the central M4 screw from the end of a bearing block and

injecting machine grease through a syringe.

Figure 26

Figure 25

Summary of Contents for Shapeoko HDZ 4.0

Page 1: ...support carbide3d com docs carbide3d com 9 2 2020 Version 4 0 1 ASSEMBLY GUIDE HDZ 4 0...

Page 2: ...support carbide3d com docs carbide3d com 9 2 2020 Version 4 0 2...

Page 8: ...support carbide3d com docs carbide3d com 8 31 2020 Version 4 0 8 Figure 2...

Page 42: ...support carbide3d com docs carbide3d com 8 31 2020 Version 4 0 42 Figure 2...