Ripping

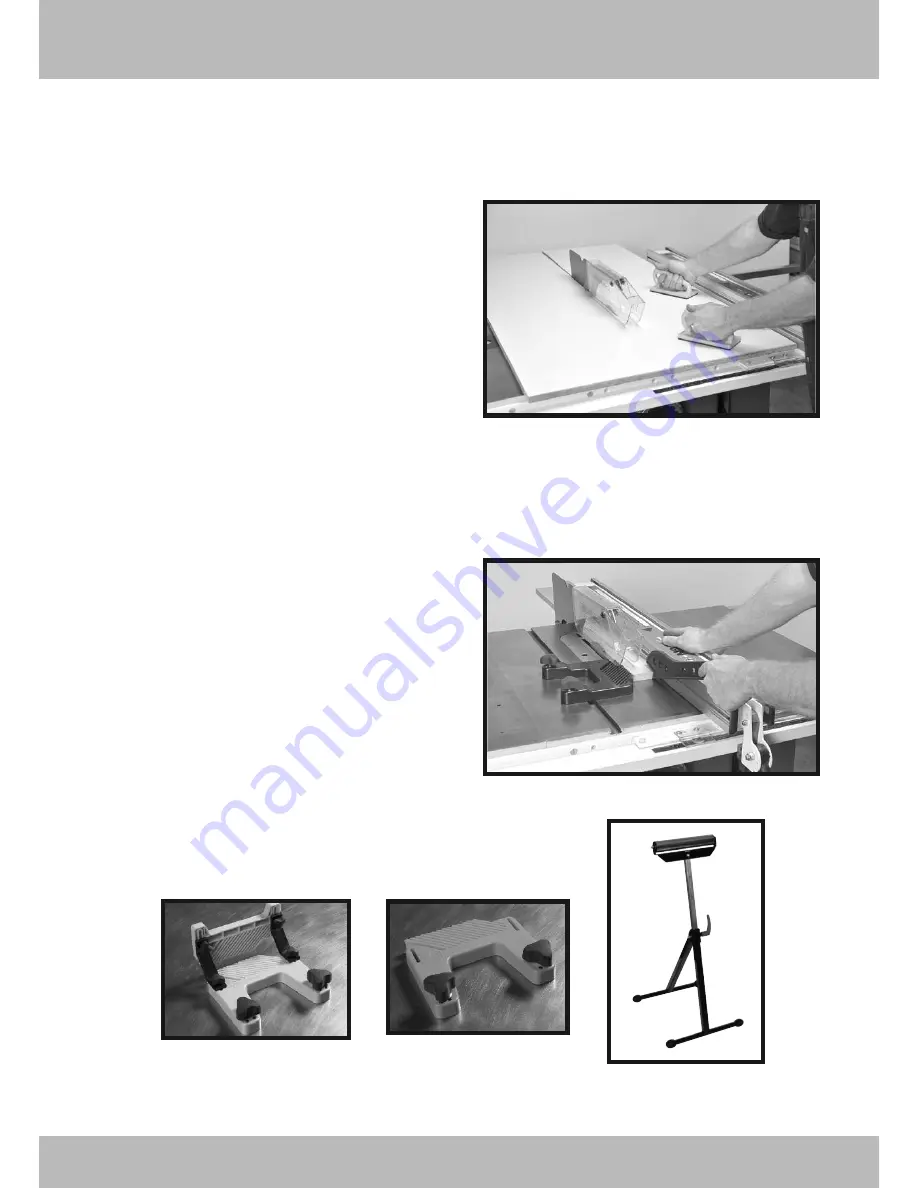

Ripping is the operation of making a lengthwise cut

through a board, and the rip fence is used to position

and guide the work. One edge of the work rides

against the rip fence while the flat side of the board

rest on the table. Since the work is pushed along the

fence, it must have a straight edge and make solid

contact with the table. The saw guard should be used

for all through cutting operations. Some blade guards

have anti-kickback fingers and most include a splitter

to prevent the saw kerf (the gap left from the cutting

action) from closing and binding on the blade.

Start the motor and advance the work holding it down

and against the fence. Never, stand in the line of the

saw cut when ripping. Hold the work with both hands

and push it along the fence and into the saw blade.

The work can then be fed through the saw blade with

one or two hands. Using push blocks will help control

your workpiece and increase safety.

Thinner workpieces may require working close to the

saw blade. Use a thin push stick to feed the work

through between the fence and the blade. -Use safety

equipment, such as featherboards, to hold you

workpiece to your fence assembly.

Your workpiece once cut completely through, should

remain held on the table by the rear of the guard, or

the anti kickback fingers. Your workpiece may also

slide to the floor when you release your pressure. If

this is going to cause damage, take maesure to

prevent this happening by seeking assistance with a

person at the rear of the table saw, or by using a

portable saw stand to support the exiting workpiece.

Your off cut waste piece should also stay on the table,

tilt up slightly and be caught by the rear end of the

guard, or slide off the table to the floor. Remember to

switch off the saw. and wait for the blade to completely

stop, before removing the off cut.

Operations

www.carbatec.com.au

21

Summary of Contents for CTH-110L 1PH

Page 31: ...Notes www carbatec com au 31...