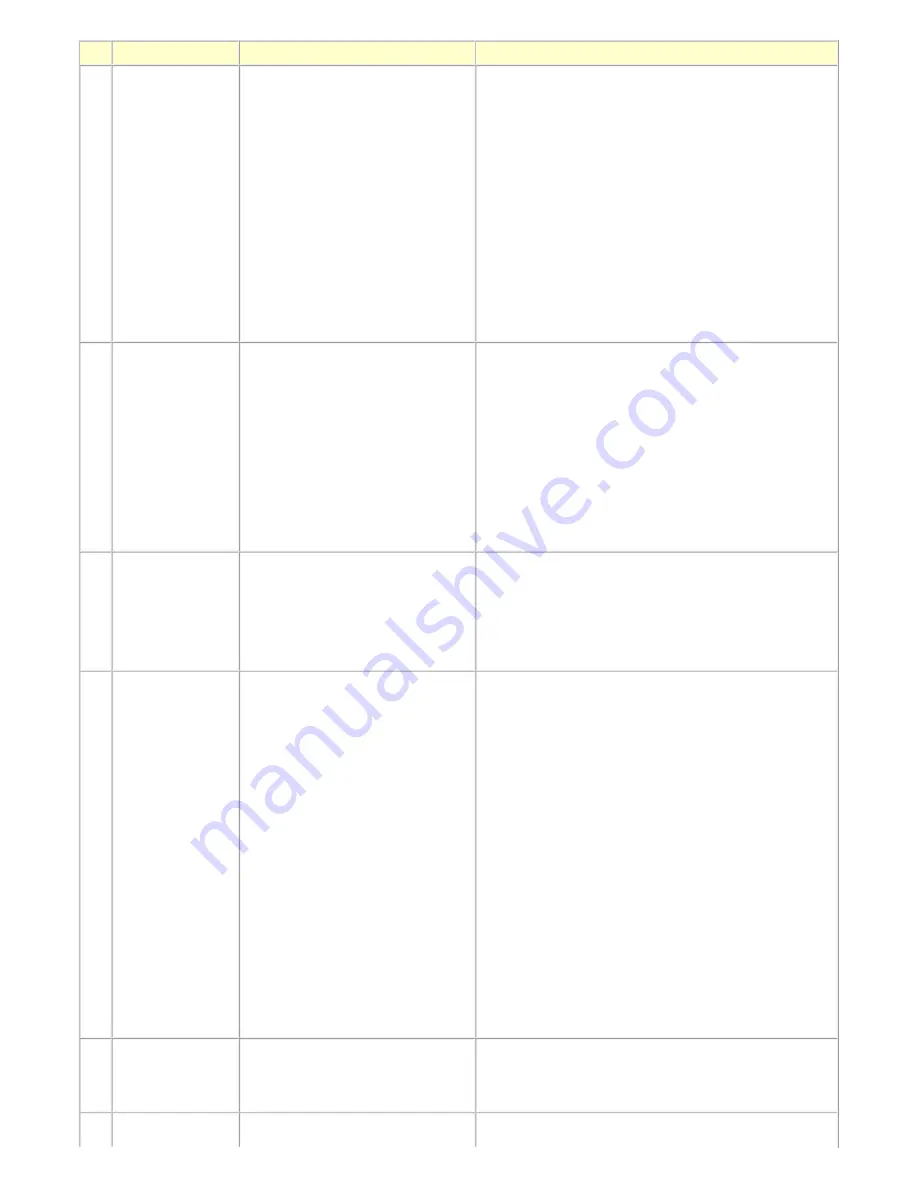

No.

Name

Function

Remarks

1 Test Print

Service test print

Paper (1 sheet of A3 or Ledger sized paper) will

feed from the rear tray.

Printed items:

- Model name

- ROM version

- USB serial number

- Process inspection information

- Barcode (model name + desti printer serial

number)

- Ink system function check result

- DVD / CD sensor check result (not applicable to

the iX6500 series)

2 EEPROM

EEPROM information print

The dialog box opens to select the paper source.

Select

Rear tray

and click

OK

(1 sheet of A4 or

Letter sized paper).

Printed items:

- Model name

- ROM version

- Ink absorber counter value

- Print information

- Error information, etc.

3 Nozzle Check

Nozzle check pattern print

The dialog box opens to select the paper source.

Select

Rear tray

and click

OK

(1 sheet of A4 or

Letter sized paper).

The same pattern as the one in the user mode is

printed.

4 Integration

Integrated inspection pattern print Paper (1 sheet of A3 or Ledger sized paper) will

feed from the rear tray.

Multiple inspection items are printed just in one

page, thus it is recommended to use this function for

the standard inspection.

Printed items:

- Model name

- ROM version

- USB serial number

- Nozzle check pattern (same as the one in the user

mode)

- Process inspection information

- Barcode (printer serial number)

- Ink system function check result

- DVD / CD sensor check result (not applicable to

the iX6500 series)

5 Auto Cleaning

Enabling / disabling of automatic

print head cleaning

Automatic print head cleaning prior to printing

(after replacement of an ink tank or the print head).

Select this option to enable the cleaning.

6 Deep Cleaning

Print head deep cleaning

Cleaning of both Black and Color at the same time

36 / 52

Summary of Contents for iX6500 Series

Page 19: ...5 Remove the panel cover unit R 1 screw 15 52...

Page 21: ...4 Remove the printer unit 6 screws Lift the printer unit Specific screw location 17 52...

Page 32: ...10 Cable wiring and connection 1 Logic board and spur unit 28 52...

Page 38: ...2 Service Tool functions Service Tool screen Version 2 000 34 52...

Page 39: ...35 52...

Page 50: ...4 2 Integrated Inspection Pattern Print Print sample 46 52...

Page 51: ...4 3 Ink Absorber Counter Value Print Print sample 4 VERIFICATION AFTER REPAIR 47 52...

Page 54: ...50 52...