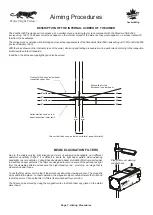

The inspection limits are a range of 4” at 25’. The illustrations below show the range allowed for vertical and horizontal inspection.

The left side of the “high intensity zone” must fall within the shaded

area for proper low beam horizontal adjustment.

The top of the “high intensity zone” must fall within the shaded area

for proper low beam vertical adjustment.

Nominal Vertical Aim Line

100 mm

100 mm

100

mm

100

mm

4"

4"

4"

0"

4"

8"

Inspection

upper limit

Inspection

lower limit

4"

0"

4"

4"

4"

Inspection

left limit

Inspection

right limit

4"

0"

4"

4"

4"

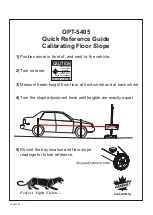

Low Beam Headlamps are aimed so that the top edge of the

high-intensity zone is at the

NOMINAL VERTICAL AIM

line,

and the left edge of the high-intensity zone is at the vertical

center line of the screen.

NOTE: Headlights centered more than 36” from the ground require beam slope compensation. See page 12 for details.

AIMING LOW BEAM HEADLAMPS

INSPECTION LIMITS FOR LOW BEAM HEADLIGHTS

There are many different beam patterns used in domestic vehicles. When checking headlights with complicated beam

patterns, you must locate the part of the high intensity zone that shines farthest down the road (is highest on the

screen) . This generally appears as a “hump” in the beam pattern. Once this is located, you simply set the left edge of

the “hump” to align with the center cross hair on the screen. You set the top of the “hump” with the horizontal cross hair.

The bottom of the “hump” typically blends into the lower portion of the beam pattern and is not considered when

adjusting the headlight.

Aiming Procedures

DIFFERENT LOW BEAM PATTERNS

Page 8 - Aiming Procedures

Canbuilt Mfg.

Perfect Night Vision.....

Summary of Contents for OPT-5405

Page 18: ......

Page 20: ...NOTES...