6-1

SECTION 6. MAINTENANCE AND TROUBLESHOOTING

These guidelines apply to several different Campbell Scientific weather stations.

6.1 MAINTENANCE

Proper maintenance of weather station

components is essential to obtain accurate

data. Equipment must be in good operating

condition, which requires a program of regular

inspection and maintenance. Routine and

simple maintenance can be accomplished by

the person in charge of the weather station.

More difficult maintenance such as sensor

calibration, sensor performance testing (i.e.,

bearing torque), and sensor component

replacement, generally requires a skilled

technician, or that the instrument be sent to

Campbell Scientific or the manufacturer.

A station log should be maintained for each

weather station that includes serial numbers,

dates that the site was visited, and maintenance

that was performed.

6.1.1 INSTRUMENTATION MAINTENANCE

The instrumentation requires a minimum of

routine maintenance. A few preventative

maintenance steps will optimize battery life and

decrease the chances of datalogger failure.

6.1.2 BATTERIES

Instruction 10 can be used to measure battery

voltage. By recording battery voltage the user

can determine how long a fresh set of batteries

will last (see the Installation Section of the

datalogger Operator's Manual for cold

temperature effects on alkaline batteries).

Short Cut and ETPro automatically program the

weather station to measure battery voltage.

When alkaline batteries are used, the battery

voltage should not be allowed to drop below 9.6

VDC before replacement. Where CR10 or 21X

dataloggers are used in the instrumentation, an

external battery must be used to maintain power

to the datalogger when changing batteries,

otherwise the clock, program, and data will be

lost (refer to the Installation Section of the

datalogger's Operator's Manual for details).

When not in use, remove the eight cells to

eliminate potential corrosion of the contact

points, and store in a cool dry place.

Rechargeable power supplies should be

connected to an AC transformer or unregulated

solar panel at all times. The charge indicating

diode should be "ON" when voltage to the

charging circuitry is present. Be aware of

battery voltage that consistently decreases over

time, which indicates a failure in the charging

circuitry.

6.1.3 DESICCANT

Enclosure humidity is monitored in the ET

Enclosure and MetData1 systems by an RH

chip incorporated into the connector board.

Change the desiccant packs when the

enclosure RH exceeds 35%. The RH chip

should be changed every 3 to 5 years.

In standard weather stations, a humidity

indicator card is provided with the enclosure. A

small RH sensor (10162) can be purchased

separately to record the RH inside the

enclosure. Change the desiccant when either

the card or the sensor read about 35% RH.

Desiccant may be ordered through Campbell

Scientific (DSC 20/4).

Desiccant packs inside of the dataloggers do not

require replacement under normal conditions.

6.1.4 SENSOR MAINTENANCE

Sensor maintenance should be performed at

regular intervals, depending on the desired

accuracy and the conditions of use. A suggested

maintenance schedule is outlined below.

1 week

•

Check the pyranometer for level and

contamination. Gently clean, if needed.

•

Visually inspect the wind sensors and

radiation shield.

1 month

•

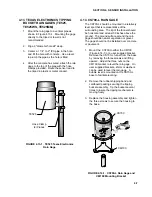

Check the rain gage funnel for debris and

level.

•

Do a visual/audio inspection of the

anemometer at low wind speeds.

•

Check the filter of the temperature/humidity

sensor for contamination.