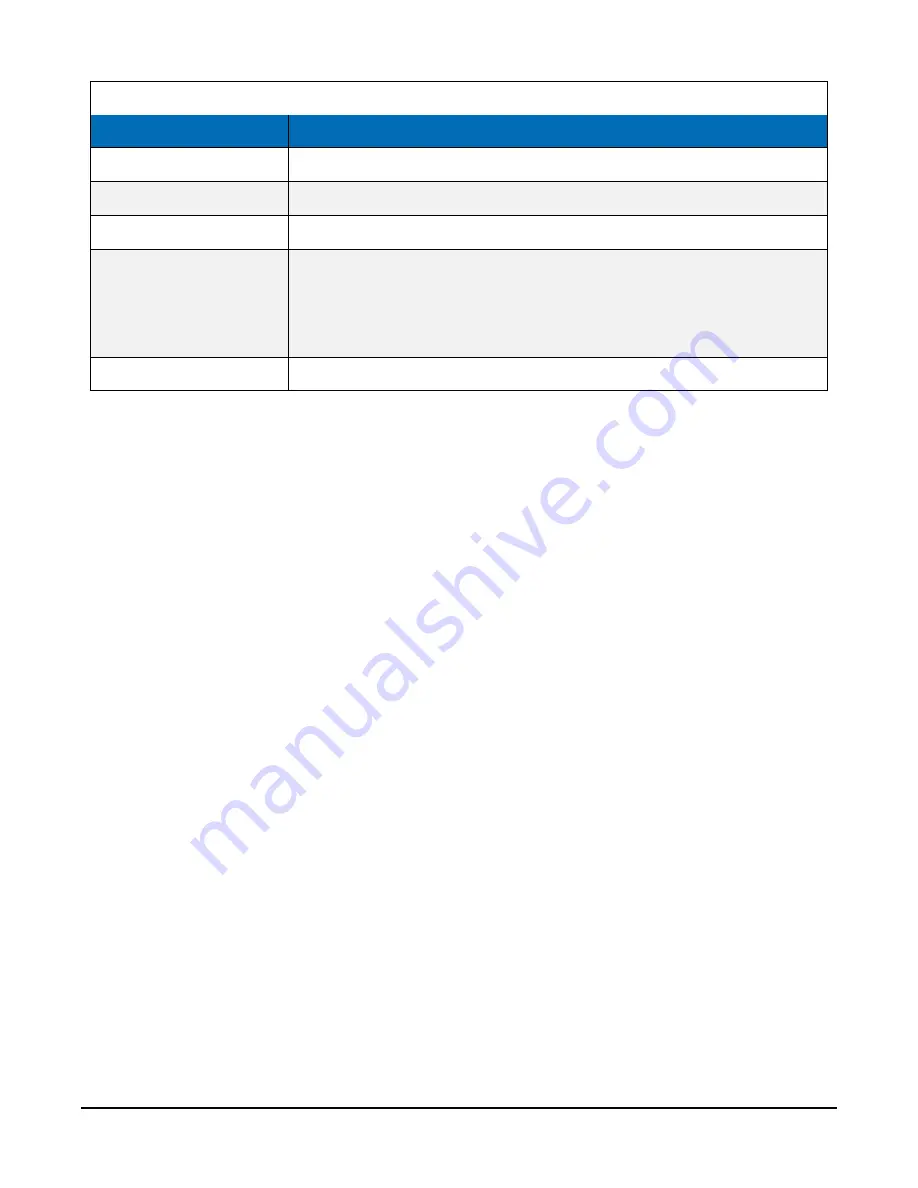

Table 7-3: Serial instructions

Instruction

Function

SerialFlush()

Clears the buffer.

Scan()

Establish a scan rate.

SerialOut()

Send command to the sensor.

SerialIn()

Set up the COM port to receive the incoming serial data. Note that in

the beginning of the CRBasic program, the variable used in the

SerialIn()

instruction needs to be declared as an ASCII string

format.

SplitStr()

Split out digital count value from the input string.

7.3 Mounting

To prevent condensation, install the sensor in an environmentally protected enclosure, complete

with desiccant. Change desiccant at regular intervals.

7.3.1 External air intake

For the sensor to detect the external ambient pressure, the enclosure must vent to the

atmosphere (not be hermetically sealed), which may require the addition of a vent hole on the

outer wall.

The preferred method is to use a two plate pressure port such as the RM Young 61002 to

minimize dynamic pressure errors due to wind.

Wind at the barometer inlet can impair measurement performance of remote barometers.

Ambient wind of 20 meters/second (45 mph) blowing over a typical barometer inlet tube can

cause dynamic pressure errors as high as 3 hPa. These errors can make atmospheric pressure

data unsuitable for research and forecast purposes. The pressure port reduces dynamic pressure

errors to a minimum level. The design of the pressure port effectively slows air velocity at the

pressure inlet. An internal baffle system creates a barrier to water and snow intrusion into the

barometer.

BaroVUE™10 Digital Barometer

11