400

600

400

50

142

220

Pa

g

e

6

- M

an

u

al

c

od

e:

11

9

B

W

4

1

E

N

11

9

B

W

4

1

E

N

ve

rs

.

4

04/

2

0

14 © C

A

M

E c

an

ce

lli

auto

m

ati

ci

s.p.a. - T

h

e d

ata a

n

d i

nf

or

m

ati

on p

rovi

d

ed

in

th

is

m

an

u

al

a

re s

u

b

je

ct to c

h

an

g

e at a

ny ti

m

e w

ith

ou

t p

ri

or n

oti

ce

by C

A

M

E C

an

ce

lli

A

uto

m

ati

ci

S

.p.a.

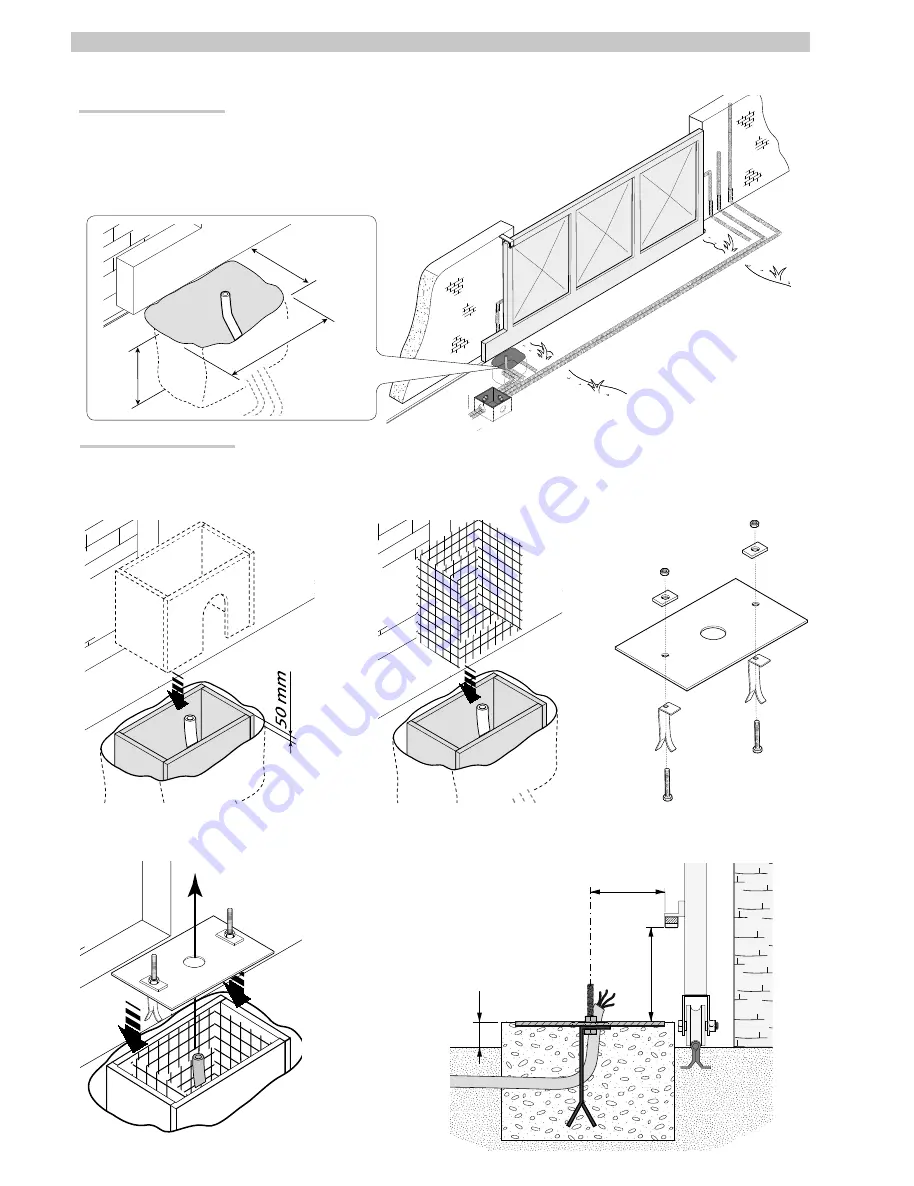

INSTALLATION

⚠

The following illustrations are only examples, given that the space for securing the operator and accessories varies depending on the overall dimensions. The

installation technician is responsible for choosing the most suitable solution.

Installing corrugated tubes

Drill the hole for the counterframe.

Prepare the junction boxes and corrugated tubes necessary for the connections from the inspection chamber. In order to

connect the gearmotor, a Ø 60 mm corrugated tube is advisable. Ø 25 mm pipes are recommended for accessories, on

the other hand.

N.B. the number of tubes depends on the type of system installed and any accessories.

Installing the mounting plate

Prepare a counterframe that is larger than the mounting plate and place it in the hole. The counterframe must protrude 50 mm from ground level.

Insert an iron grid inside the counterframe to reinforce the concrete.

Secure the anchor brackets to the plate using the screws, nuts and washers supplied.

Position the mounting plate, respecting the measurements shown on the drawing, if the rack is already present.

Caution! The tube must pass through the prepared hole.

All manuals and user guides at all-guides.com

all-guides.com