14

LP GAS HOOKUP

LP GAS HOOK UP:

(TYPE 1 OR QCC1 REGULATOR):

Grills orifices for use with LP gas come equipped with a high capacity hose/regulator assembly for connection to

a standard 20 lb. LP cylinder (Type 1). The LP tank is not included.

Connection:

1/2” NPT male with a 3/8” Flare adapter (included). LP Hose with a quick disconnect and fittings are

included. Operating pressure: 11.0” W.C.

CAUTION!

Before connecting LP tank to regulator, check that all grill burners valves are in the OFF position and open grill lid.

To connect the LP regulator/hose assembly to the tank/valve assembly, first make sure the main valve on the tank

is completely closed. Although the flow of gas is stopped when the Type 1 system is disconnected as part of its

safety feature, you should always turn off the LP tank main valve after each use and during transport of the tank or

unit. Insert the regulator inlet into the tank valve and turn to the black coupler clockwise until the coupler tightens

up. Do not overtighten the coupler. Turn the main tank valve on and turn the burner control valves on the unit to

the “HI” position for about 20 seconds to allow the air in the system to purge, turn valves off and wait 5 minutes

before attempting to light the burners.

To disconnect the coupler, first make sure the main tank valve is turned off. Grasp the coupler and turn counter

clockwise. The inlet will then disengage. Remove the inlet from the tank valve opening if it has not already done so

when it disengaged. Your local LP filling station should be equipped with the proper equipment to fill your tank.

LP TANK REQUIREMENTS:

A dented or rusty LP tank may be hazardous and should be checked by your LP supplier. The cylinder that is used

must have a collar to protect the cylinder valve. Never use a cylinder with a damaged valve. Always check for leaks

after every LP tank change. The LP gas cylinder must be constructed and marked in accordance with the specifica-

tions for LP gas cylinders of the U.S. Department of Transportation (DOT or CAN/CSA-B339) and designed

for use with a Type 1 system only. Do not change the regulator/hose assembly from that supplied with the unit or

attempt to use a Type 1 equipped regulator/hose assembly with a standard 510 POL tank/valve assembly. The cyl-

inder must be provided with a shut-off valve terminating in an LP gas supply cylinder valve outlet specified, as ap-

plicable, for connection Type 1. If the appliance is stored indoors, the cylinder must be disconnected and removed

from the appliance. Cylinders must be stored outdoors in a well-ventilated area out of the reach of children.

*Installation must conform with local codes or with the National Fuel Gas Code ANSI Z223.1 or the CAN/CGA-

B149.2 Propane Installation Code

NATURAL GAS HOOK UP

(THIS TYPE OF CONNECTION SHOULD BE PERFORMED BY A CERTIFIED OR LICENSED TECHNI-

CIAN ONLY.)

Connection: 1/2” NPT male with 3/8” flare adapter. Operating pressure: 4.0” W.C. Supply pressure: 5” to 14”

water column. If in excess of 14” W.C., a step down regulators required. Check with your local gas utility company

or local codes for instructions on installing gas supply lines. Be sure to check on type and size of run, and how deep

to bury the line. If the gas line is too small, the grill will not function properly. Any joint sealant used must be an

approved type and be resistive to the actions of LP gases.

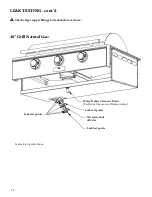

TO HOOK-UP THE FITTINGS SUPPLIED WITH THE GRILL:

Assemble and leak test as shown in the previous pages illustrations. Use threading compound on male threads only.

Do not use threading compound on the male end of the 1/2 NPT to 3/8 flare adapter. Use a second pipe wrench

to hold the grill inlet pipe to avoid shifting any internal gas lines of the grill. Ensure that the regulator arrow points

in the direction of gas flow towards the unit, away from the supply. Do not forget to place the installer-supplied gas

valve in an accessible location.