46

cab - Produkttechnik GmbH

Warning Sensors

The sensors recognize, when the diameter of the label supply roll respectively

the transfer ribbon roll decreases below a preset thresould value.

NOTICE !

The messages of the sensors are only intended to inform the operator.

They do not influence the operation of the Hermes, i.e. the operation is

not interrupted.

The messages will be shown by switching on the yellow lamp of the warning

light (option). The signals also can be sent to a control system by using the

peripheral interface.

Warning Sensor Label End

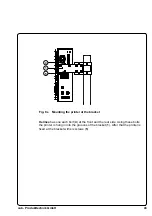

Mounting

1. Switch off the printer

2. Slide the sensor holder (1) with the warning sensor label end (2) behind the

wind plate (6) of the media supply hub.

3. Attach the sensor holder with the slotted head screw (7) and the hexagon

socket head screw (3) to the mounting plate. The hexagon socket head

screw (3) must be used at this side, where the elongated hole is located in

the sensor holder.

4. Plug the cable (4). For that Hermes 4 has a 5-pin connector at the rear

side of the frame. The connector (10) at Hermes 5 is beside the control

panel.

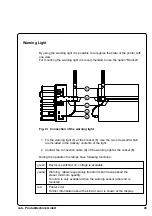

Adjustment

With this setting the threshold diameter (3.3 to 4.3 in / 84 to 110mm) for the

warning message can be adjusted.

1. Slide a label roll (9) with the intended threshold diameter onto the media

supply hub.

2. Switch on the printer. The sensor (2) sends out a beam (5). If the label roll

does not interrupt the path of the beam, the beam is mirrored at the

reflective foil (8) and detected again by the sensor. In that case the LED at

the sensor is on.

3. Loosen the hexagon socket head screw (3) and swing the sensor holder

against the axle of the media supply hub as near as possible.The LED at

the sensor is off.

4. Slowly swing the sensor holder away from the axle until the LED at the

sensor goes on.

5. Tighten the hexagon socket head screw (3).

Summary of Contents for Hermes 4F

Page 27: ...27 cab Produkttechnik GmbH ...

Page 50: ...50 cab Produkttechnik GmbH ...