27

6.9

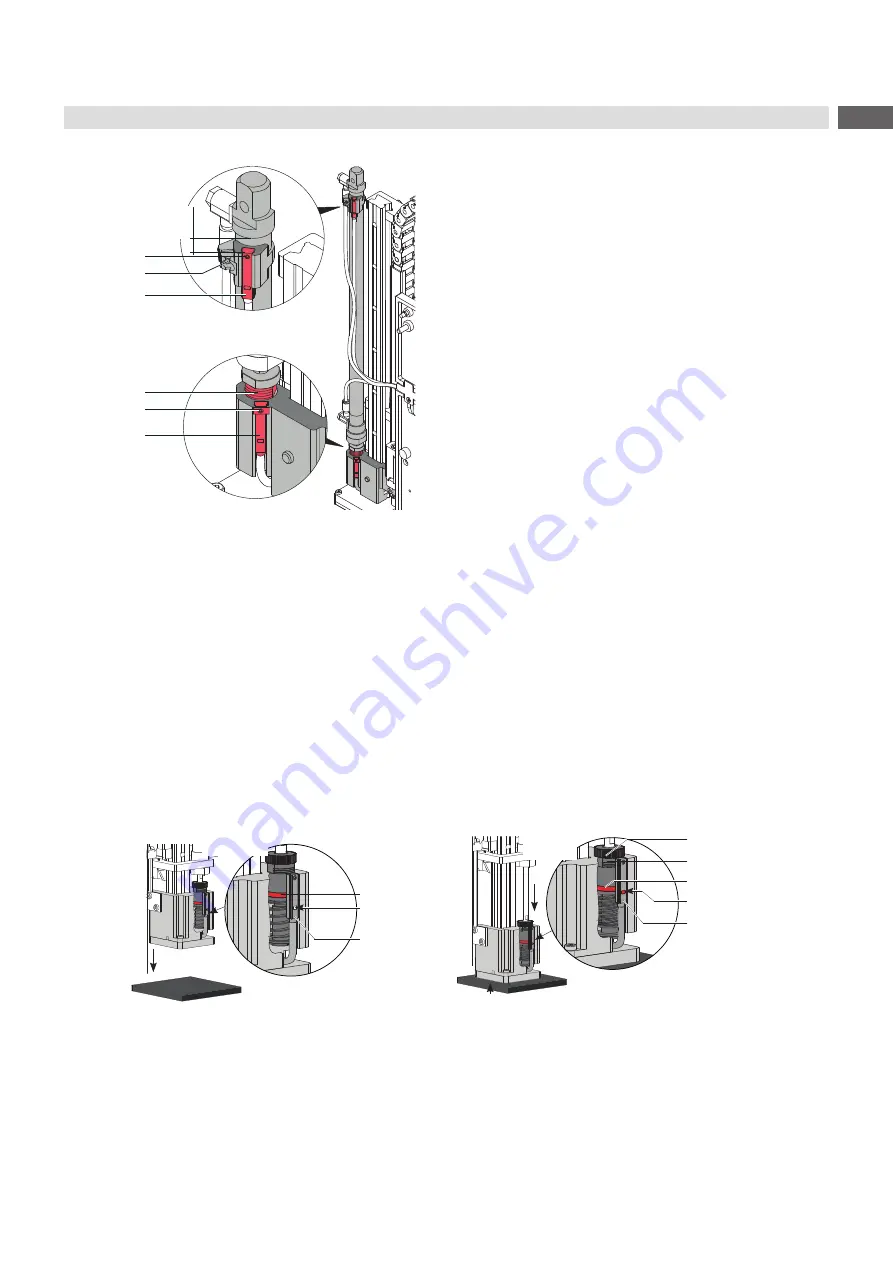

Sensors on Cylinder Z

1

3

2

4

5

6

8mm

Fig. 27

Sensors on cylinder Z

Sensor Start Position (3) Cylinder Z

1. Loosen screw (1) of sensor "Start Position" (3) and move the sensor so that the top edge of the sensor sits

comfortably in the sensor holder.

2. Remove the compressed air tubes of the cylinder Z and power up the printer with connection to the applicator.

3. Move the pad toward the stopper manually.

4. Loosen screw (2) of the sensor holder.

5. Position the sensor so that it triggers securely with lit up LED at complete contraction of cylinder Z. This is

achieved with the top edge of the sensor being about 8 mm from the top edge of the connection ring.

6. Tighten screw (2).

Sensor End Position (6) Cylinder Z

The sensor End Position (6) is to be mounted flush with the upper edge of the punch holder.

Depending on the weight of the punch and the installation position, the tension of the spring in the adapter bolt is set

in order to avoid unintentional triggering of the sensor End Position (6). The triggering magnet is integrated in the

adapter bolt and varies its position when the spring tension changes.

Magnet

Detection point

in sensor

Sensor

Pad free

Pad on

product

Magnet

Detection point

in sensor

Sensor

Setting nut, black with

cut-out 13mm

Knurled nut

Fig. 28

Labelling sensor principle

1.

Getting the printer and applicator into the final orientation.

2. Adjust the spring tension on the adapter bolt (4) via the black setting nut so that:

•

The adapter bolt is not pushed into the stamp assembly group during motion.

•

The sensor triggers when the pad has reached the labeling position.

3.

Turn the setting nut with an open spanner 13 mm and fix the knurled nut by holding it.

- Turning the setting nut clockwise will increase the spring tension.

- Turning the setting nut counterclockwise will decrease the spring tension. Loosen screw (5) and move the

sensor (6) so that the LED lights up when the adapter bold is pushed into the pad assembly.

4. Tighten screw (5).

Summary of Contents for 4414 Series

Page 1: ...Service Manual 4414 MADE IN GERMANY Stroke Applicator...

Page 36: ...36 36 9 Drawings 9 2 Pneumatic drawing Type 4414 Fig 40 Pneumatics Type 4414...

Page 37: ...37 9 Drawings 9 3 Label position Type 4414 L Fig 41 Label position 4414L...

Page 38: ...38 38 9 Drawings 9 4 Label position Type 4414 R Fig 42 Label position 4414R...