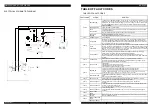

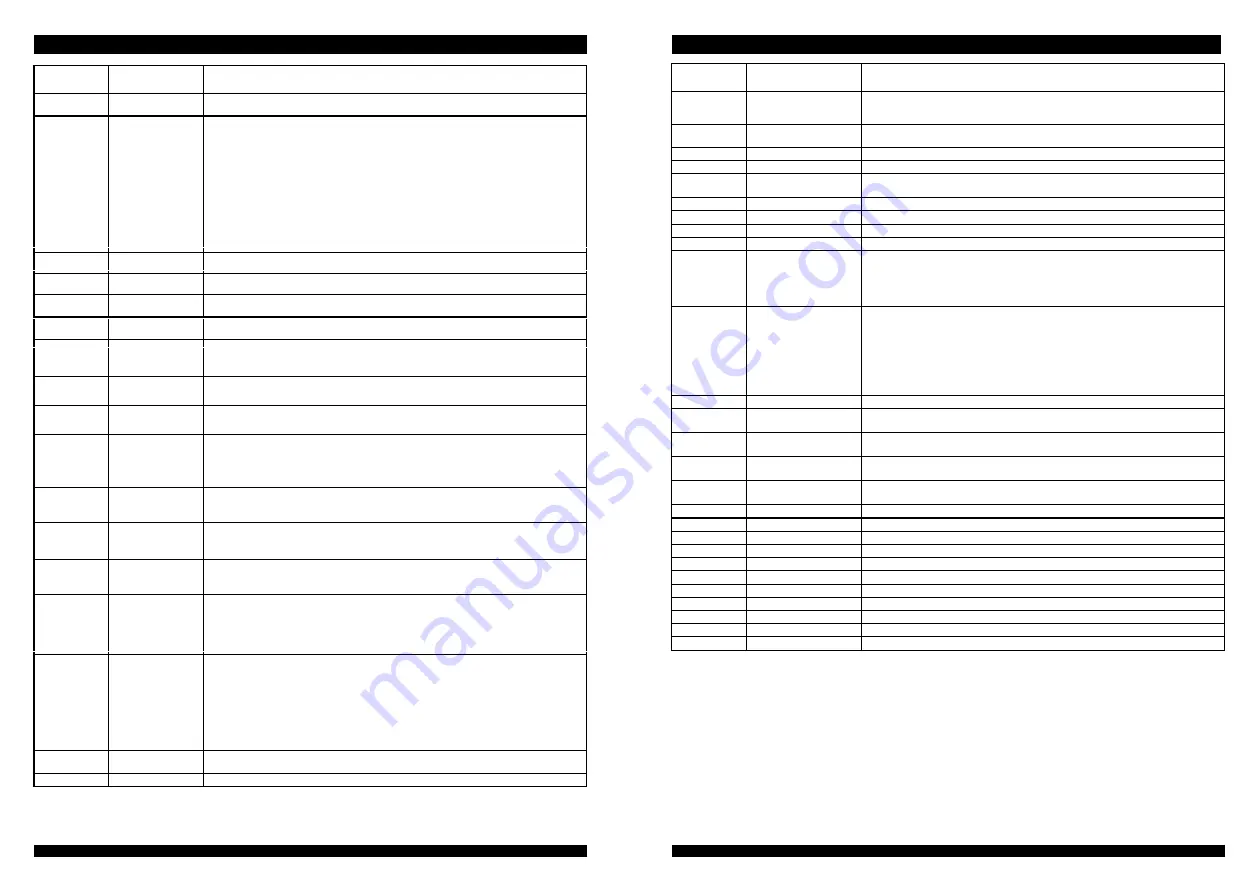

06A11

DATA ACQUISITION This activated fault proves that it is in the data acquisition phase. Please wait until the

data acquisition is complete

.

06A12

LOGIC FAILURE #1

A fault that occurs in the low-voltage or over-voltage protection state. In a 24V system,

the controller detects a voltage of more than 45V

or less

than 9V; In a 48V

system, the

controller detects

a voltage of more than 65V or

less than 11V.The possible causes are:

1.

Whether there is a short circuit in the circuit system, such as DC-DC, brake coil, etc.,

or whether

the input

power of the controller is in good condition.

(walking controller)

2.

Whether the battery voltage is too low or too high.(walking controller)

3.

Whether the power cables on the terminals such as B+, B, and the main contactor

are fastened. (walking controller)

4.

Whether the voltage calibration parameter of controller is consistent with the actual

voltage. (walking controller)

5.

The hardware circuit of the over-voltage protection on the logic card is faulty. Replace the

controller. (walking controller)

6.

The voltage between W phase and U phase does not meet the requirements. Replace the

controller. (steering controller)

06A13

LOGIC FAILURE #2 The voltage between W phase and V phase does not meet the requirements. Replace the

controller. (steering controller)

06A14

LOGIC FAILURE #3 The output VU-VV of the voltage amplifier exceeds 2.2V-2.8V. Replace the controller (steering

controller).

06A15

LOGIC FAILURE #4

The output VW-VV of the voltage amplifier exceeds 2.2V-2.8V. Replace the controller

(steering controller).

06A16

KS CLOSED

The main contactor detects that the safety contactor of the slave contactor is closed in

advance. Replace the controller.

06A17

KM CLOSED

The slave contactor detects that the safety contactor of the main contactor is closed in

advance. Replace the controller.

06A18

KS OPEN

The main contactor detects that the safety contactor of the slave contactor is not closed in time.

Replace the controller.

06A19

KM OPEN

The slave contactor detects that the safety contactor of the main contactor is not closed in time.

Replace the controller.

06A20

MAIN CONT. OPEN

The logic card has driven the main contactor coil, but the contactor is not closed. Possible

causes are as follows:

1. Mechanical failure of contactor or stuck, etc.

2. Poor contact of the contactor.

3. If the contactor works properly, replace the controller.

06A21

MICRO SLAVE

Replace the controller.

06A22

S.P OUT OF RANGE

If a single potentiometer, such as CPOC1 end, exceeds the range of 0.8v-4.2v, an alarm will be

raised. When a dual potentiometer is selected, the sum of the two sliding ends

(CPOC1+CPOC2) exceeds the range of 4.4v-5.5v, an alarm will be raised. Check the

connection of the potentiometer.

06A23

F.B OUT OF RANGE

When the feedback potentiometer (CPOT connected to CNB # 6) is faulty, an alarm will be

raised. If the range of CPOT exceeds the range 0.3V-4.7V, an alarm will be raised. Check if

the steering motor encoder is connected correctly and whether there is a circuit break.

06A24

MICRO SLAVE KO

1.

When a stepper motor is used, the direction of the main microprocessor is inconsistent with

that of the stepper motor detected from the slave microprocessor.

2.

In the closed-loop control system, the direction of the stepper motor detected by the main

contactor is wrong and inconsistent with the direction of the stepper motor detected from the

slave contactor.

3. The main contactor did not detect the steering limit, but the slave contactor did.

06A25

ENCODER ERROR

The controller detected a significant difference in the two consecutive speed readings of

the encoder since

the

internal encoder cannot change the speed very much in a short time.

Check the mechanical and circuit functions of the encoder to make sure if the encoder

is

faulty

(the circuit of

one or two encoders

is worn or broken); Or the alarm

may be

caused by electromagnetic

interference on the sensor

bearing. If neither, replace the

controller. Please note that manual operation may also cause this fault. In this case, you

need to power off

and restart

the vehicle.

For example:

1.The vehicle suddenly hit an obstacle and was unable to walk;

2. Slam on the brake at high speed.

06A26

BAD ENCODER

SIGN

Exchange encoder A phase and B phase;

06A27

GAIN EEPROM KO

Replace the controller;

06A28

CAN BUS KO

1. Check if CAN BUS communication cable is connected well; 2. Check if the

communication baud rate is consistent; 3. Check if CAN communication is on;

4.

Check if CAN communication loop resistance is 60Ω.

06A38

POSITION

1. Check if the connection of A phase and B phase of steering motor encoder is loose.

2. Check if A phase and B phase of the steering motors are disturbed.

06A39

SERIAL ERROR

Replace the controller.

06A40

MICRO SLAVE #4

Replace the controller.

06A41

SLAVE COM. ERROR

Replace the controller.

06A43

CURRENT GAIN

Replace the controller.

06A44

CLOCK PAL NOT OK

Replace the controller.

06A45

STEER SENSOR KO

Check if the wiring and output of two-way angle potentiometer is correct.

06A46

JERKING FB

Replace feedback potentiometer;

06A47

FB POT LOCKED

1. Check if there is mechanical loosening of the feedback angle potentiometer;

2. Check if there is a mechanical limit;

3. Check if the feedback angle potentiometer reaches its own limit point;

4. If this fault occurs due to the reverse direction of the steering wheels during installation,

adjust the direction of the steering wheels.

06A48

MOTOR TEMPERAT.

1.

This fault occurs if the motor temperature digital switch is turned on, or the analog

signal

exceeds the cutoff value.

2.

When the motor temperature reaches 120

℃

, the controller gives an alarm, at which

point the vehicle can still walk, but the maximum current is reduced,

so does the

performance of the vehicle. When the motor temperature reaches 125

℃

, the motor

stops working, and you should try to cool the motor.

3. If the fault still exists when the motor cools down, check the wiring. If all is good,

replace

the controller.

06A49

MOTOR LOCKED

The time of maximum sustained current of the steering motor exceeds 1s.

06A50

STEPPER MOT MISM

Replace the controller.

06A52

MICRO SLAVE #8

Replace the controller.

06A53

INPUT ERROR #1

Check if CAN # 4 connection cable is correct.

06A54

CAN BUS KO SL.

Replace the controller.

06A55

SL EPS NOT ALL.

Replace the controller.

06A56

SL CENTERING

Replace the controller.

16A06

Check the CAN cables of the handle, instrument and steering controller.

17A01

battery high temp.waring

17A02

battery high temp.alarm

17A03

battery leakage waring

17A04

battery leakage serious

17A05

battery Status Alarm

17A06

BDI low

17A07

BDI low

17A08

BDI low

USER MANUAL

7

2

7

3

OM-

EPS14Pi

2019001-EN

MAINTENANCE OF VEHICLES

EPS14Pi

FAULT

CODE

ALARM

REMEDY

FAULT

CODE

ALARM

REMEDY