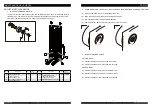

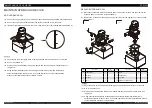

MAINTENANCE OF VEHICLES

EPS14Pi

USER MANUAL

6

4

6

5

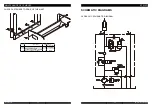

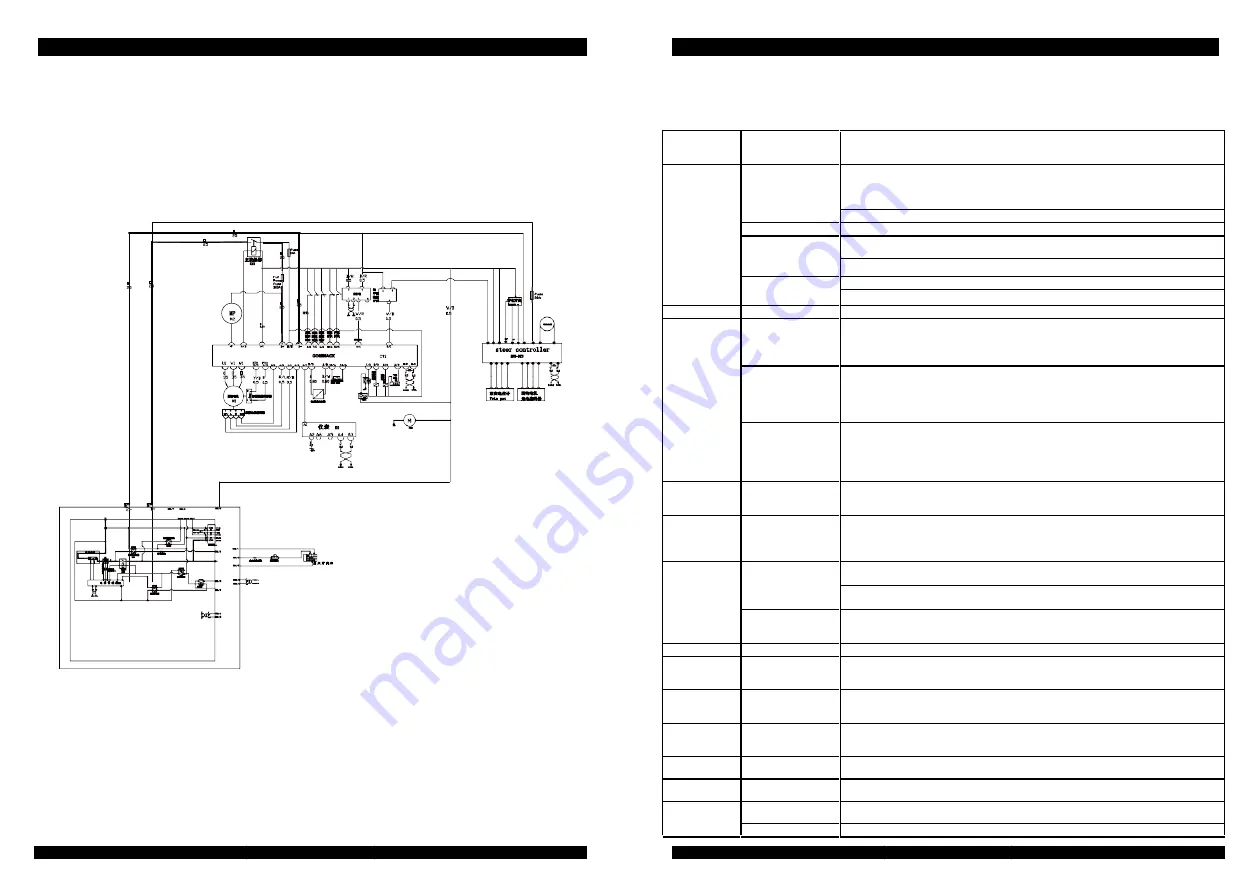

ELECTRICAL SCHEMATIC DIAGRAM

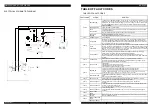

TABLE OF FAULT CODES

FAULT

CODE

ALARM

REMEDY

02A00

BATTERY LOW

If parameters of “BATTERY CHECK” are not set as “0”, the fault will be reported, and the

lifting function will

be locked when the battery power

is

less than 15% and no bars are

displayed on the instrument. Please charge in time. If the battery is electric, check whether

the

value of“ADJUST BATTERY” on the controller

is consistent with that

of battery voltage.

EPS RELE OPEN

DATA

ACQUISITION

If the fault is activated to show that it is in a phase of data acquisition, please wait until data

is acquired completely.

Don’t operate during date acquisition. Restart after data is acquired.

CHECK UP

NEEDED

When the maintenance time is up, check it.

Revise CHECK UP DONE into ON. Shut down and restart

02A01

WRONG CONFIG

Clear EEPROM

02A08

WATCHDOG

Watchdog circuit will be activated before software starts. Under working or standby states,

the signal of watchdog is ineffective (warning state). Fault analysis: a broken state has been

seen in the watchdog hardware circuit or the microcontroller output part. If both of the above

two are irrelevant with outer parts, replace the controller.

FLASH

CHECKSUM

After the key is turned on, the value of flash checksum on the program is positive. If it is

negative, the signal of fault will appear. Fault analysis: It

is blamed for the flash memory of

microcontroller. The flash checksum may be broken, or the program stored suffered from

damage. Try to reset the pro-gram of the logic card. If the fault continues,

it should be

blamed for

the microcontroller. Replace the controller.

WATCHDOG#2

Cause: The Watchdog circuit will be activated before software starts. Under working or

standby states, the signal of watchdog is

ineffective (warning state).

Fault analysis: A broken state has been seen in the watchdog hardware circuit or the

microcontroller output part. If both of the above two are irrelevant with outer

parts, replace the

controller.

02A10

WRONG RAM

Find faults when performing tests for main ram: the registration address is “DIRTY”.

The fault will

limit the operability of forklifts. Fault

analysis: Close the key switch and open

again. If the fault still

exists, replace the controller.

02A11

STALL ROTOR

1.Motor stalls.

2.Fault appears in the encoder of the motor.

3.Wiring harnesses is broken or fault is found in the wiring.

4.The encoder is disabled in its power supply.

02A13

EEPROM KO

1. Restart the electric lock. Please replace the controller if the fault still exists.

2. Restart the electric lock. Please reset parameters if the fault disappears.

Perform CLEAR EEPROM. If the fault disappears, change the parameters

as set values singly. Instead, try to replace the controller.

PARAM RESTORE

If CLEAR EEPROM has been performed, change the prompt parameters of fault as a default

value.

If not, there is a fault inside the controller.

02A16

AUXOUTPUT KO

Check whether the coil of electromagnetic brake is normal. If not, replace the controller.

02A17

LOGIC FAILURE

#3

The output circuit of coil suddenly disconnects during operation.

A fault is found in the current protection function of the logic card. Replace the

controller.

02A18

LOGIC FAILURE

#2

1. Check whether the circuit of motor power line is normal, including the safety device of the

controller. 2. Check the parameter list.

3. If it is bot blamed for the above two, replace the controller.

02A19

LOGIC FAILURE

#1

1. Check battery voltage.

2. Check whether ADJUST BATTERY of the controller is consistent with actual voltage of

the battery.

02A20

HEIGHT SENS

OPEN

02A21

CHARGE

SAFETY

When it is charging, any movement of forklifts will report the fault. It can protect forklifts from

being operated when charging.

02A22

HEIGHT SENS

LOCK

LOCK

RESET CUTBACK

1

Charge the battery.

Check if the EPS controller is faulty.

TABLE OF FAULT CODES

OM-

EPS14Pi

2019001-EN