Page 30 of 106

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

KENDO.30LIGHT-KENDO.30LIGHTFI

7105-M002-0_B

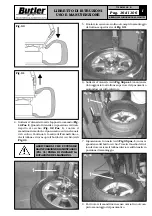

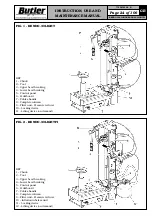

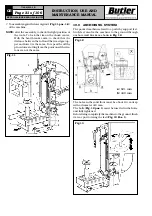

Fig. 10

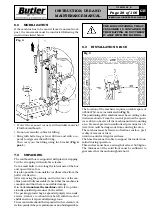

9.3

Electrical connection

EVEN THE TINIEST PROCEDURE

OF AN ELECTRICAL NATURE

MUST BE CARRIED OUT BY PRO-

FESSIONALLY QUALIFIED

STAFF.

As envisaged by the regulations in force, the machine is

not equipped with a master circuit breaker, but simply

has a plug-socket connection to the electrical mains.

The machine is supplied with

3

mt. of free cable. A plug

corresponding to the following requirements must be

connected to the cable:

• Conformity to Norm

IEC 309

•

230/400 Volt – 16A

•

2P + Ground

•

IP 44

VERSION WITH

MONOPHASE MOTOR

On delivery, the machine is preset to operate at a voltage

of 200 ÷ 265 V - 50/60 Hz monophase.

9.4

Working area modification

After the delivery, the machine is prearranged to operate

on wheel of 41” maximum diameter and a rim diameter

(10” - 26”). It’s possible to move the tools column to

enlarge the working area from 43” (with rim diameter of

12” - 28”) to 45” (with rim diameter of 14” - 30”) (see

Figure 10

).

The column handling is possible unscrewing the fixing

screws of the base (

Fig. 10 pos. A

) to the column (

Fig.

10 pos. B

) and sliding the base (

Fig. 10 pos. A

) into the

proper slots until the required measure.

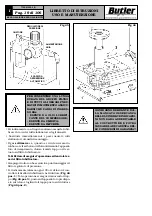

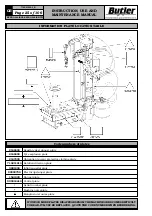

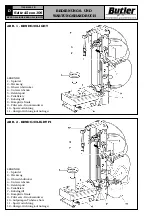

MAKE SURE THAT THE TYRE

CHANGING MACHINE COLUMN IS

STABLE USING A CABLE WITH A

BLOCK TO LOCK ON THE LIFTING

CROSS BEAM (FIG. 11 POS. 7).

1. To remove the lateral guard (

Fig. 11 pos. 1-2

) of the

machine.

2. To unscrew the screws (

Fig. 11 pos. 3

) and the nuts

near the central slots (

Fig. 11 pos. 4

) playing atten-

tion to not remove the nuts from the proper screws.

3. To remove six remained screws (

Fig. 11 pos. 5

).

4. To move the base (

Fig. 11 pos. 6

) into the required

position (to 43” or 45”) and if necessary to use a lift-

ing device (

Fig. 11 pos. 7

).

5. To lock the base three screws (

Fig. 11 pos. 3

) with a

couple of 80 Nm.

6. To place six screws (

Fig. 11 pos. 5

) previously re-

moved and to lock them on the base side with a cou-

ple of 80 Nm.