Page 27

29877 080301

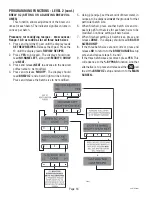

ENABLE ADS?

This function allows the operator to choose whether

or not to display the advertising message that was

entered into the brewer with an

AD CARD

. This mes-

sage will be displayed when the brewer is not in use.

Procedure to Enable/Disable Ads

:

1. Press and hold the ® pad until the display reads

SET NEW RECIPES

. Release the ®. Press and

release the ® until the display reads

ENABLE ADS

.

The

YES

or

NO

will be flashing to indicate the

current selection.

2. Press and release the

NO

pad to disable this

function (no ads will be displayed on the screen),

or;

3. Press and release the

YES

pad to enable this

function (ads will be displayed on screen).

4. When finished, press and release

DONE

to save the

new setting, exit the

ENABLE ADS

function and

advance to the next function screen,

SET TEMP.

Another alternative is to press and release either of

the

pads located on the front switch panel to

exit the

ENABLE ADS

function and return to the

MAIN SCREEN.

SET TEMP - Range: 185˚F (85˚C) to 205˚F (96˚C)

This function allows the operator to set the brew

water temperature in the tank. It also sets the hot water

faucet dispense temperature.

P2301

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

P2302

Procedure to set brew temperature:

1. Press and hold the ® pad until the display reads

SET NEW RECIPES

. Release button. Press and

release the ® until the display reads

SET TEMP

.

P2303

Procedure to set ready temperature:

1. Press and hold the ® pad until the display reads

SET NEW RECIPES

. Release the ® pad. Press and

release the ® pad until the display reads

SET

READY

.

2. To adjust the ready temperature, press the

(-)

button to decrease, or

(+)

to increase the ready

temperature.

3. When finished, press and release

DONE

to save the

new setting, exit the

SET READY

function and

advance to the next function screen,

REFILL.

Another alternative is to press and release either of

the

pads located on the front switch panel to

exit the

SET READY

function and return to the

MAIN SCREEN.

2. To adjust the brew temperature, press

(-)

to de-

crease or

(+)

to increase the brew temperature.

3. When finished, press and release

DONE

to save the

new setting, exit the

SET TEMP

function and

advance to the next function screen,

SET READY.

Another alternative is to press and release either of

the

pads located on the front switch panel to

exit the

SET TEMP

function and return to the

MAIN

SCREEN.

SET READY - Range: 185˚F (85˚C) to 203F (95C)

This function allows the operator to set the mini-

mum temperature allowable to start a brew cycle. The

range can be from 185˚F (85˚C) to within 2˚F of the

SET

TEMP.

The water must be at the

SET READY

tempera-

ture or higher for the display to indicate

READY TO

BREW

. If brew lockout is enabled, the brewing process

will not start below this

READY

temperature.

NOTE:

The upper limit is the water temperature control

setting minus 2˚F (-17

°

C).