Page 4

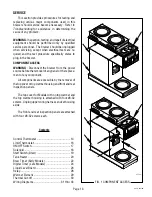

PLUMBING REQUIREMENTS

Models S & SA:

These models are completely portable and require no attached plumbing.

Models ST, STA, STF & STFA

These brewers must be connected to a cold water system with operating pressure between 20 and 90 psi (138

and 620 kPa) from a

1

⁄

2

" or larger supply line. A shut-off valve should be installed in the line before the brewer. Install

a regulator in the line when pressure is greater than 90 psi (620 kPa) to reduce it to 50 psi (345 kPa). The water

inlet fitting is

1

⁄

4

" flare.

NOTE -

Bunn-O-Matic recommends

1

⁄

4

" copper tubing for installations of less than 25 feet and

3

⁄

8

" for more than

25 feet from the

1

⁄

2

" water supply line. A tight coil of copper tubing in the water line will facilitate moving the brewer

to clean the countertop. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The

size and shape of the hole made in the supply line by this type of device may restrict water flow.

ELECTRICAL REQUIREMENTS

CAUTION -

The brewer must be disconnected from the power source until specified in

Initial Set-Up.

Model 15

has an attached cordset and requires 2-wire grounded service rated 120 volts ac, 15 amp, single

phase, 60 Hz.

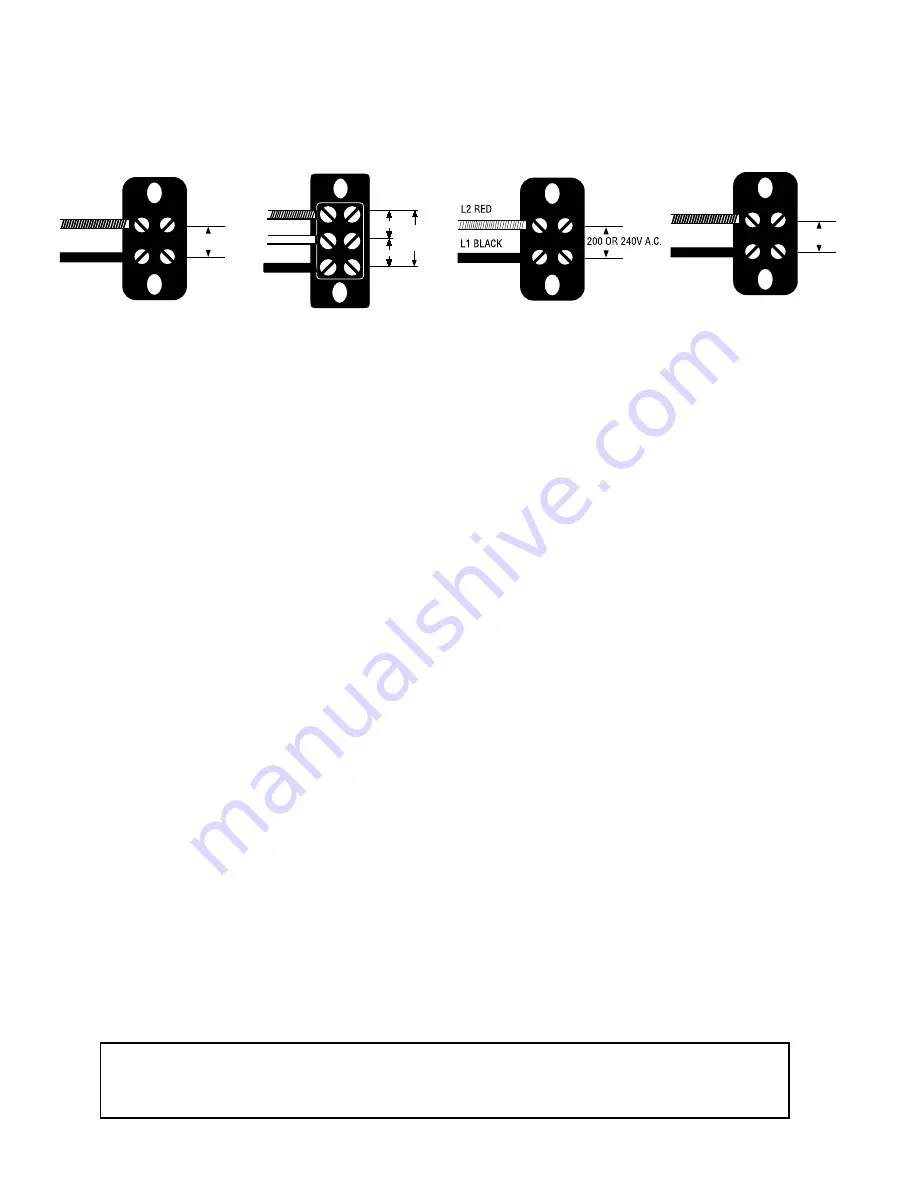

Model 35

requires 3-

wire, grounded service

rated 120/208 or 120/240

volts ac, 20 amp, single

phase, 60 Hz. Proceed as

follows:

Model 20

requires 2-

wire, grounded service

rated 120 volts ac, 20

amp, single phase, 60 Hz.

Proceed as follows:

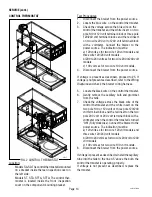

Electrical Hook-Up

CAUTION –

Improper electrical installation will damage electronic components.

1.

An electrician must provide electrical service as specified.

2.

Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

3.

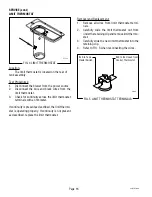

Before electrically connecting the brewer, remove the front and rear panel and rotate the thermostat knob fully

counterclockwise to the "OFF" position. Keep this knob in the "OFF" position until performing the "Initial Set-Up"

4.

Feed the power cord through the strain relief and connect it to the terminal block.

5.

Connect the brewer to the power source and verify the voltage at the terminal block before proceeding.

(Models S and ST-15 have cord attached. Replace all panels.

6.

If plumbing is to be hooked-up later be sure the brewer is disconnected from the power source. If plumbing

has been hooked-up, the brewer is ready for "Initial Set-Up".

NOTE: Schematic wiring diagrams are included in this manual.

“A" & "B”

models re-

quire 2-wire, grounded

service rated 200 volts ac

or 240 volts ac, 20 amp,

single phase, 50 Hz. Pro-

ceed as follows:

"SDB”

model requires

2-wire, grounded service

rated 100 volts ac, 20

amp, single phase, 50 Hz.

Proceed as follows:

This equipment must be installed to comply with the Basic Plumbing Code of the Building

Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation

Manual of the Food and Drug Administration (FDA).

29251 011800

P1841

L2 RED

NEUTRAL

L1 BLACK

120V A.C.

120V A.C.

208 or

240V.A.C.

WHITE

NEUTRAL

L1 BLACK

120V.A.C.

WHITE

NEUTRAL

L1 BLACK

100V.A.C.

WHITE

P2185

P2185

P2193

Summary of Contents for S

Page 31: ...Page 31 29251 052500 ...

Page 32: ...Page 32 29251 052500 ...

Page 33: ...Page 33 29251 052500 ...

Page 34: ...Page 34 29251 052500 ...

Page 35: ...Page 35 29251 052500 ...

Page 36: ...Page 36 29251 052500 ...

Page 37: ...Page 37 29251 052500 ...

Page 38: ...Page 38 29251 052500 ...

Page 39: ...Page 39 29251 052500 ...

Page 40: ...Page 40 29251 052500 ...

Page 41: ...Page 41 29251 052500 ...

Page 42: ...Page 42 29251 080400 ...

Page 43: ...Page 43 29251 052500 ...

Page 44: ......