Page 22

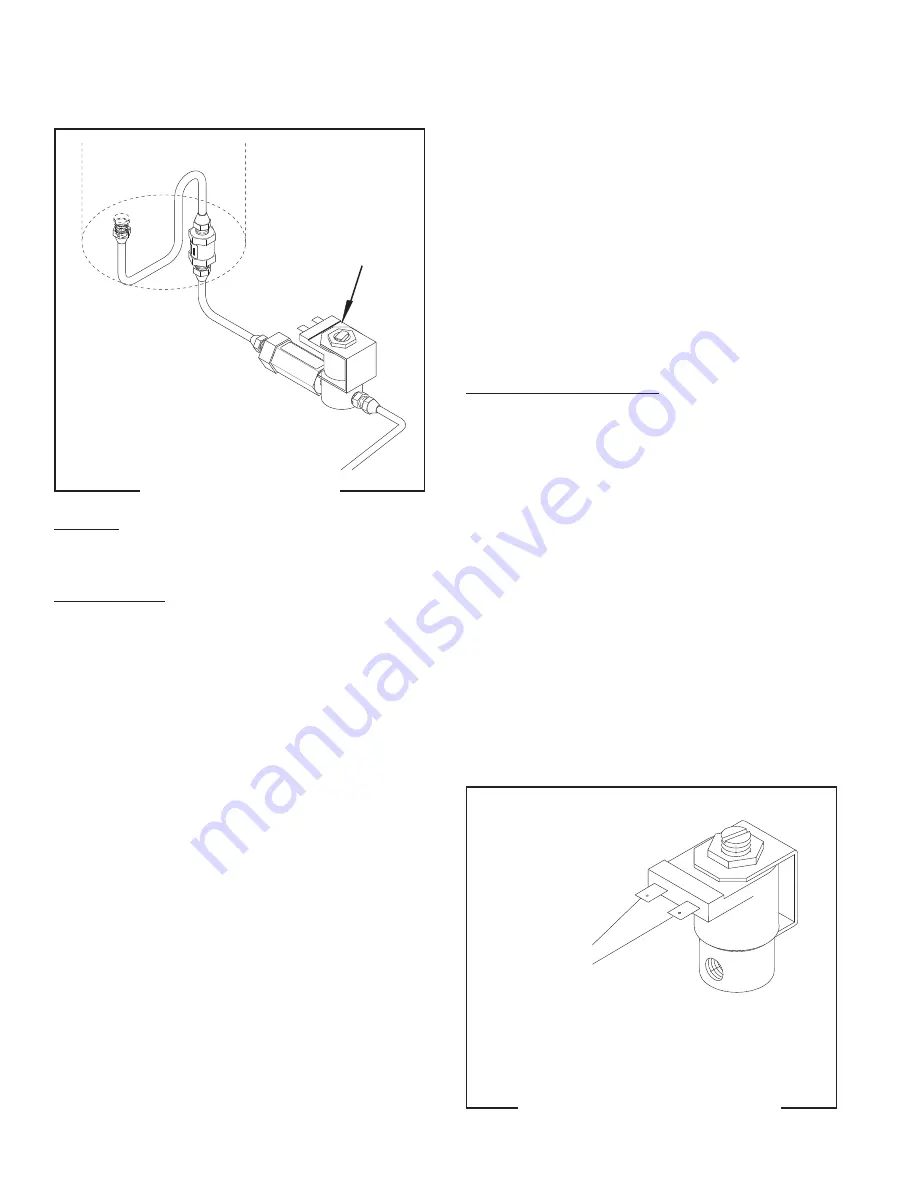

FIG. 21 SOLENOID VALVE

FIG. 22 SOLENOID VALVE WIRING

SERVICE (cont.)

Solenoid Valve

4. Check the solenoid valve for coil action. Connect

the brewer to the power source, place the On/Off

brew station warmer switch in the upper posi-

tion, press and release the start switch. Listen

carefully in the vicinity of the solenoid valve for a

“clicking” sound as the coil magnet attracts and

after the approximate setting on the brew timer

dial, repels the plunger.

5. Disconnect the brewer from the power source.

If the sound is heard as described and water will not

pass through the solenoid valve, there may be a block-

age in the water line before or after the solenoid valve

or, the solenoid valve may require inspection for wear,

and removal of waterborne particles.

If the sound is not heard as described, replace the

solenoid valve.

Removal and Replacement:

1. Remove all wires from the solenoid valve coil.

2. Turn off the water supply to the brewer.

3. Remove the bottom pan attached with one or

more 8-32 slotted-head screw(s) beneath the

front of the brewer.

4. Raise the brewer approximately six inches from

the counter top and support the feet on something

sturdy.

5. Disconnect the water lines to and from the sole-

noid valve.

6. Remove the two 10-32 screws holding the sole-

noid valve to the bracket.

7. Lift-out the solenoid valve.

8. Securely install the new solenoid valve to the

bracket. Check the direction of flow arrow on

the valve. It must be pointing toward the flow

control.

9. Securely fasten the water lines to and from the

solenoid valve.

10. Refer to FIG. 22 when reconnecting the wires.

Location:

The solenoid valve is located below and to the left of

the tank as viewed from the rear, FIG. 21.

Test Procedure:

1. Check the voltage across the white and black

wires with a voltmeter when the On/Off brew sta-

tion warmer switch is in the upper position and

the start switch is pressed to the lower position

and released. Connect the brewer to the power

source. The indication must be:

a) 120 volts ac for two wire 120 volt models and

three wire 120/240 volt models,

b) 200 or 240 volts ac for two wire 200 volt or

240 volt models,

c) 100 volts ac for two wire 100 volt models,

for the approximate setting on the brew timer dial

and then return to zero.

2. Disconnect the brewer from the power source.

If voltage is present as described, proceed to #3.

If voltage is not present as described, refer to the Wir-

ing Diagrams and check the brewer wiring harness.

3. Check for continuity across the solenoid valve

coil terminals.

If continuity is present as described, reconnect the

white and black wires and proceed to #4.

If continuity is not present as described, replace the

solenoid valve.

BLK to Brew Timer

WHI to Brew Timer

P1699

P1588

32440 070700

Part II

Summary of Contents for OL

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 27: ...Part I ...

Page 48: ... BUNN HOUSINGS PANELS ModelOL OL RL OT RT _ b _ _ 16 15 14 RevisedDecemberl999 Part I ...

Page 50: ... BUNN HOUSlNGS PANELS ModelRL D I a OL RL OT RT 2 P1649 6 RevisedDecember1999 Part I ...

Page 54: ... BUNN HOUSlNGS PANELS ModelRT OL RL OT RT P1651 IO RevisedDecember1999 Part I ...

Page 60: ...BUNN TANK COMPONENTS ModelsOT RT OL RL OT RT P1653 16 RevisedDecemberl999 Part I ...

Page 62: ...BUNN STRAlNER ModelsOL RL OL RL OT RT 9 8 IO 7 P1654 18 RevisedDecember1999 Part I ...

Page 68: ...BUNN WARMER ASSEMBLIES ModelsOL OT OL RL OT RT P1657 24 RevisedDecember1999 Part I ...

Page 72: ......

Page 73: ......

Page 76: ...ELECTRICAL OPERATING CONTROLS ModelRL OL RL OT RT 32 RevisedDecember1999 Part I ...

Page 78: ...Part I ...

Page 82: ...Part I ...

Page 86: ...BUNN 8 FUNNELS BASKETS OL RL OT RT 47 RevisedDecember1999 Part I ...

Page 90: ......

Page 92: ......

Page 170: ...44 BUNN OL RL OT RT FUNNELS BASKETS P1663 1 2 3 6 4 5 7 9 6 7 1 8 10785 010708 Part II ...

Page 174: ......