www.bullard.com

4

Oper

ations / Br

eathinig Air Requir

ements

Operations

Protection

Respiratory

The RT Series respirator is NIOSH approved (TC-19C-412) as a Type C

continuous-flow supplied air respirator. It can be worn for general purpose

applications, including pharmaceutical manufacturing, chemical and pesticide

handling, tank cleaning, spray painting, and other industrial or agricultural

applications in which hazardous compounds are present.

The RT Series respirator is not approved for use in any atmosphere

immediately dangerous to life or health (IDLH), or from which the wearer

cannot escape without the aid of the respirator. IDLH is defined in 29 CFR

1910.134(b)

Head

RT Series respirator hoods DO NOT provide head protection.

Face

RT Series respirator hoods DO NOT provide face protection. If face protection

is required, use the Bullard 20TICH or 20SICH model.

Eyes

RT Series respirator hoods DO NOT provide eye protection. Wear approved

safety glasses or goggles at all times.

Ears

RT Series respirator hoods DO NOT provide hearing protection. Use properly

fitted earmuffs, earplugs or other protection when exposed to high noise

levels.

RT Series Respirator Breathing Air Requirements

Air Quality

Respirable, breathable air must be supplied to the point-of-attachment of

the approved Bullard air supply hose. The point-of-attachment is the point

at which the air supply hose connects to the air source. A pressure gauge

attached to the air source is used to monitor the pressure of air provided to

the respirator wearer (see Figure 2).

Supplied breathing air must AT MINIMUM meet the requirements for Type 1

gaseous air described in the ANSI/Compressed Gas Association Commodity

Specification G-7.1 for Grade D or higher quality as specified by Federal

regulations 42 CFR, Part 84.141(b) and 29CFR1910.134(i).

The requirements for Grade D breathable air include:

Oxygen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19.5-23.5%

Hydrocarbons (condensed) in mg/m3 of gas . . . . . . . . . . . . . . . 5 mg/m3 max.

Carbon monoxide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 ppm max.

Carbon dioxide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,000 ppm max.

Odor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *

No toxic contaminants at levels that make air unsafe to breathe.

*Specific measurement of odor in gaseous air is impractical. Air may normally

have a slight odor. The presence of a pronounced odor should render the air

unsatisfactory.

Contact the Compressed Gas Association (1725 Jefferson Davis Highway,

Arlington, VA 22202) or www.cganet.com for complete details on Commodity

Specification G-7.1.

Air Source

Locate the source of supplied air, whether it is a breathing air compressor

or an ambient air pump, such as a Bullard Free-Air® pump, in a clean air

environment. Locate the air source far enough from your work site to ensure

the air remains contaminant-free. Always use an inlet filter on your air

source.

Use suitable after-cooler/dryers with filters, and carbon monoxide monitors

and alarms, as necessary to assure clean, breathable air at all times.

Compressed air should be regularly sampled to be sure that it meets Grade D

requirements.

RT Series Respirator Breathing Air Pressure

Air pressure should be monitored at the point-of-attachment while operating

this respirator. A reliable air pressure gauge must be present to permit you to

monitor pressure during actual respirator operation.

Special or Critical User’s Instructions

The Breathing Air Pressure Table (see page 5) defines the air pressure ranges

necessary to provide RT Series respirators with a volume of air that falls

within the required range of 6-15 cfm or 170-425 lpm (Ref. 42 CFR, Part 84,

Subpart J, 84.150).

Make sure you understand the information in the Breathing Air Pressure Table

before using this respirator.

1. Determine the type of air source you are using (Column 1), then find your

flow control valve/climate control device (Column 2).

2. Be sure your Bullard air supply hose (Column 3) is approved for use with

your flow control valve/climate control device.

3. Determine that your Bullard air supply hose is within the approved length

(Column 4).

4. Make sure you have not exceeded the maximum number of hose sections

(Column 5).

5. Set the air pressure at the point-of-attachment within the required

pressure range (Column 6) for your flow control valve/climate control device,

and air supply hose type and length.

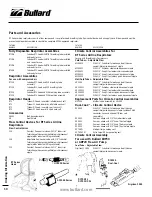

RT Series Respirator Breathing Air Supply Hoses

and Hose Fittings

NIOSH approved Bullard air supply hose(s) MUST be used between the

breathing tube connection fitting on the wearer’s belt and the point-of-

attachment to the air supply.

NIOSH approved Bullard quick-disconnect fittings MUST be used to connect

V5 or V20 hose lengths together. When connecting lengths of V10 hose, only

use Bullard V11 hose-to-hose adapters. Secure connection(s) until wrench-

tight and leak-free. Total connected hose length and number of hoses MUST

be within the ranges specified on the Breathing Air Pressure Table (see page

5).

The breathing tube connection fitting MUST be secured to the belt that is

supplied with this respirator. Securing the breathing tube connection helps

prevent the air supply hose from snagging, disconnecting or pulling the

respirator hood off your head.

WARNING

The RT Series respirator must be supplied with clean, breathable air,

Grade D or better, at all times. This respirator does NOT purify or filter

out contaminants. Failure to heed these warnings could result in death

or serious injury.

WARNING

Failure to supply the minimum required pressure at the point-of-attach-

ment for your hose length and RT respirator type will reduce airflow and

could result in death or serious injury.