www.bssindustrial.co.uk

38

Commissioning

Filling

First you must ensure that the pressure in the expansion vessel is the same as the setting of the

pressure reducing valve i.e. 3 bar (45PSI). The valve is of the Schrader car tyre type. Check all the

connections for water tightness including any factory made connections such as the immersion heater

and the temperature and pressure relief valve. Prior to filling, open the hot tap furthest away from the

cylinder to expel air. Open the cold main isolation valve and allow the unit to fill.

Once the cylinder has been fully commissioned it should be heated to its normal operating

temperature. Draw off secondary hot water to each outlet and allow hot water to flow from each

outlet for at least 30 seconds to remove any flux residue from the pipe work within the secondary

hot water system. Then fully drain the cylinder and re-fill to ensure that all flux residues are removed

from the system.

Indirect Units

Fill the primary circuit according to the boiler manufacturers’ commissioning instructions. Any

additives used in the heating system water circulating through the cylinder coil must be compatible

for use with stainless steel cylinders.

Ensure the lever on the two port valve is set to the filling position. When full, move the lever back.

Switch the programmer to Domestic Hot Water (DHW) and allow the unit to start to heat. Adjust the

dial of the dual thermostat to between 30°C and 70°C as required.

Storage Temperature

60-65°C is the recommended storage temperature for both Multi Energy and Indirect cylinders. In

hard water areas consideration should be given to reducing this to 50-55°C. In many healthcare

applications the guidance on Legionella control and safe water delivery temperatures will require

storing the water at 60-65°C, distributing at 50-55°C and using thermostatic mixing valves to control

the final temperature. For details consult the NHS Estates Guidance on safe hot water temperatures.

Summary of Contents for BOSS 100

Page 4: ...www bssindustrial co uk 4 ...

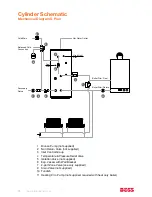

Page 31: ...Boss Direct Indirect Installation Guide 31 Cylinder Schematic Electrical Diagram S Plan ...

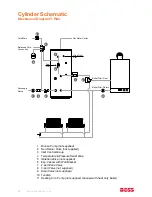

Page 33: ...Boss Direct Indirect Installation Guide 33 Cylinder Schematic Electrical Diagram Y Plan ...

Page 44: ...www bssindustrial co uk 44 48 Direct Indirect Mains Pressure Benchmark Checklist ...

Page 45: ...Boss Direct Indirect Installation Guide 45 49 Water Storage System Commisioning ...

Page 47: ...Boss Direct Indirect Installation Guide 47 Notes ...