DS4800 REFERENCE MANUAL

10

1

Focus Lock/Unlock

You must perform the

Focus Lock

procedure to save the mechanical focus position to

memory. If the mechanical focus position is changed by more than the allowed tolerance of

the value in memory, a diagnostic alarm will be sent to the display.

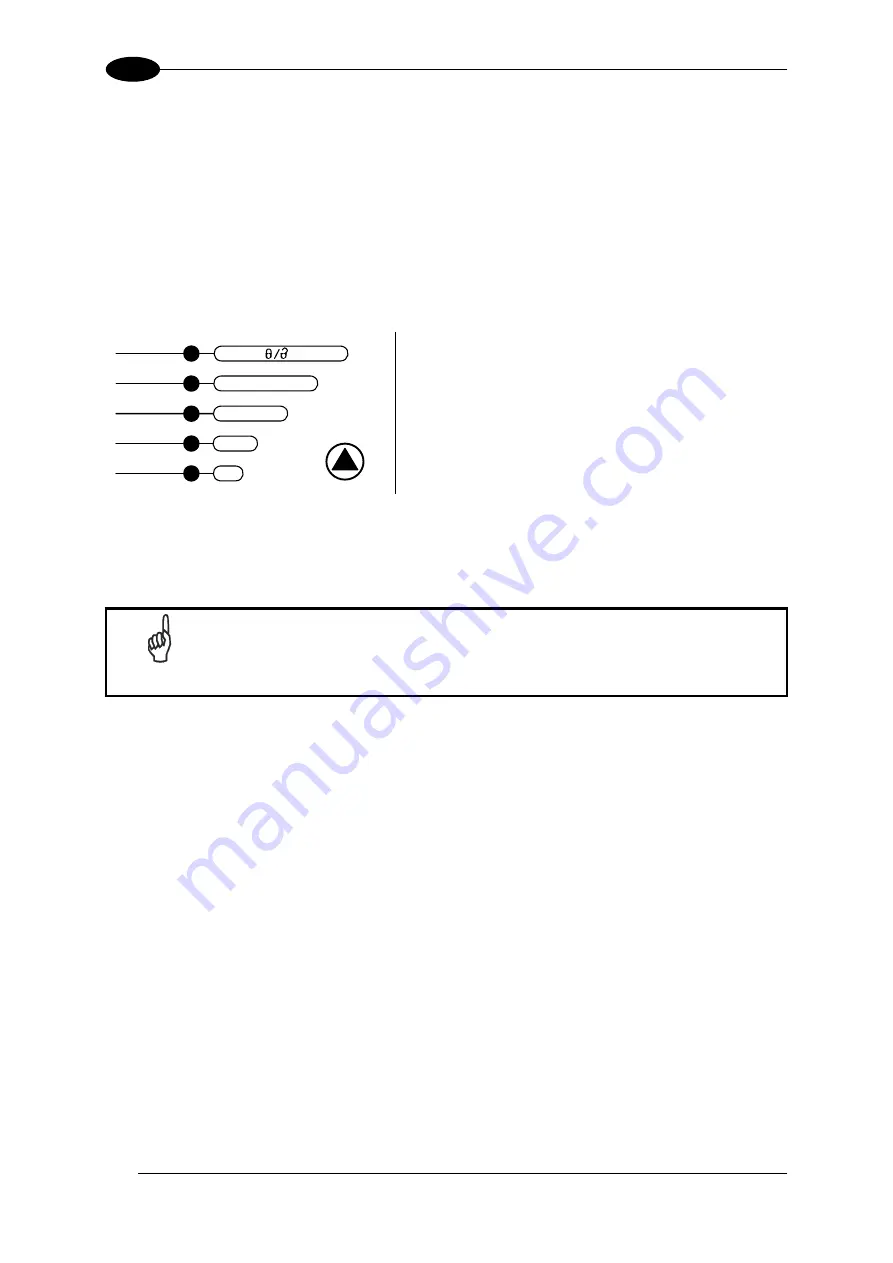

1. Enter the Focus Lock function by holding the X-PRESS™ push button pressed until the

FOCUS LOCK LED is on.

2. Release the button to enter the

Focus Lock

function.

Once entered, the scanner automatically performs the Lock (saving) or Unlock procedure

depending on the previous state of the Locked Position parameter.

green

green

yellow

yellow

red

READY

GOOD

TRIGGER

COM

STATUS

SETUP

LEARN

TEST

FOCUS

Figure 10 – X-PRESS™ Interface: Focus Lock/Unlock

Function

The procedure is as follows:

A)

enter

the Focus Lock function

B)

wait

until the "Focus locked at..."

message appears on the display

(indicating the focus position has

been saved to memory). The

following parameters are set:

Locked Position = your mechanical

setting

Focus Displacement (Alarm) = set

(default to display only)

The scanner will restart at the end of the process.

NOTE

If your application has been configured using X-PRESS™, go to STEP 6.

Reset Scanner to Factory Default (Optional)

If it ever becomes necessary to reset the scanner to the factory default values, you can

perform this procedure by holding the X-PRESS™ push button pressed while powering up

the scanner. At the end of the procedure (about 5-6 seconds), the Configuration and

Environmental parameters are reset, all LEDs blink simultaneously 3 times and the message

"Default Set" is shown on the display.